The absolute most critical practice for maximizing cowboy boot durability is establishing a strict rotation schedule. You must avoid wearing the same pair of boots on consecutive days to prevent rapid material degradation.

Core Takeaway Leather is a porous, organic material that absorbs moisture during wear, leading to bacterial growth and structural breakdown. By rotating between pairs, you allow the boots sufficient time to dry out and "rest," which significantly extends the lifespan of both the leather upper and the internal footbed.

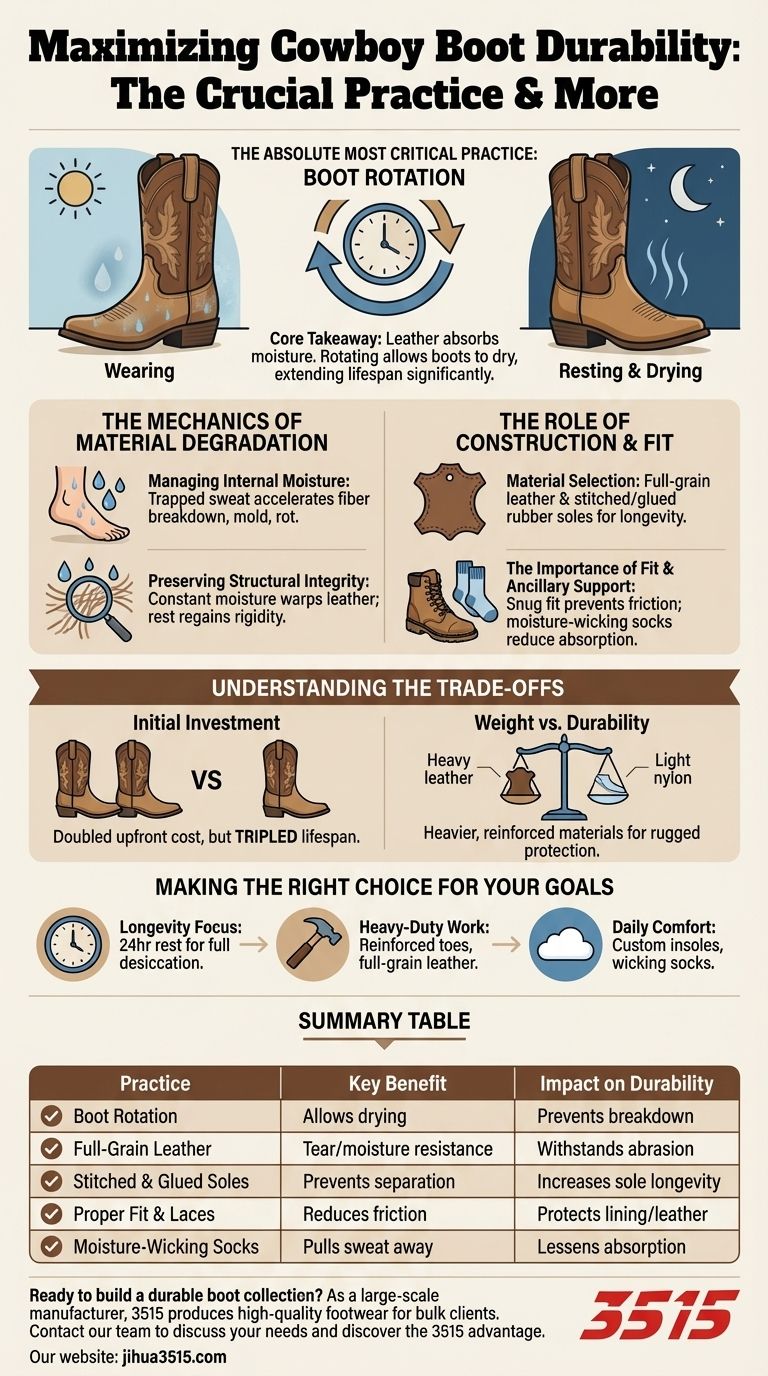

The Mechanics of Material Degradation

To understand why rotation is non-negotiable, you must understand how cowboy boots fail.

Managing Internal Moisture

Your feet perspire throughout the day, and leather absorbs this dampness.

If you wear the boots again before they have fully dried, the moisture remains trapped. This accelerates the breakdown of fibers and encourages mold or bacteria, which can rot the stitching and lining from the inside out.

Preserving Structural Integrity

Boots rely on the leather's ability to hold a shape.

Constant moisture makes leather overly pliable and prone to warping. A rest period allows the fibers to regain their rigidity, ensuring the boot maintains its support and shape over years rather than months.

The Role of Construction and Fit

While rotation is the behavioral key, the physical makeup of the boot dictates its maximum potential lifespan.

Material Selection

For genuine longevity, full-grain leather is superior. It resists tearing and moisture damage better than processed alternatives.

Furthermore, look for rubber soles that are glued and stitched. This dual-attachment method prevents sole separation, a common failure point in cheaper boots.

The Importance of Fit

Durability is also a function of how the foot interacts with the boot.

Properly tightening laces (if applicable) or ensuring a snug instep fit prevents the foot from sliding. Excessive movement creates friction, which wears down the inner lining and stresses the leather at flex points.

Ancillary Support

Using moisture-wicking socks is a force multiplier for durability. They pull sweat away from the foot, reducing the amount of moisture the leather absorbs in the first place.

Understanding the Trade-offs

While maximizing durability is the goal, practical constraints exist.

The Initial Investment

The "rotation" strategy requires owning at least two pairs of high-quality boots.

While this doubles your upfront cost, it typically triples the lifespan of both pairs compared to wearing a single pair daily until failure.

Weight vs. Durability

To achieve maximum toughness, manufacturers often use reinforced toe areas and heavier leathers.

This increases the weight of the boot. You may have to sacrifice the lightweight feel of nylon or softer leathers to gain the rugged protection needed for heavy use.

Making the Right Choice for Your Goals

Durability is not a one-size-fits-all metric; it depends on how you use the boots.

- If your primary focus is longevity: Establish a 24-hour resting period between wears to allow full desiccation of the leather.

- If your primary focus is heavy-duty work: Prioritize boots with reinforced toes and full-grain leather to withstand external abrasion.

- If your primary focus is daily comfort: Utilize custom insoles and moisture-wicking socks to reduce internal friction and moisture buildup.

Treat your boots as a system that requires recovery time, and they will return the favor with years of service.

Summary Table:

| Practice | Key Benefit | Impact on Durability |

|---|---|---|

| Boot Rotation | Allows leather to dry completely | Prevents fiber breakdown & mold |

| Full-Grain Leather | Superior tear & moisture resistance | Withstands abrasion and wear |

| Stitched & Glued Soles | Dual-attachment prevents separation | Increases sole longevity |

| Proper Fit & Tight Laces | Reduces internal friction | Protects lining and leather at flex points |

| Moisture-Wicking Socks | Pulls sweat away from the foot | Lessens moisture absorption by leather |

Ready to build a durable boot collection that lasts?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable work and cowboy boots built with longevity in mind, using premium materials like full-grain leather and robust construction techniques.

Let us help you provide your customers with boots that stand the test of time. Contact our team today to discuss your bulk footwear needs and discover the 3515 advantage.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- How much water pressure can waterproof boots withstand? A Guide to Waterproof Integrity

- How should one choose between work boots and dress boots? Find the Right Boot for Your Needs

- How do boots with electrical hazard protection work? Safeguard Your Workforce with 3515 EH Boots

- How do EH-rated work boots protect against electrical hazards? Insulate Against Shock with Certified Safety

- What are some common safety risks associated with inadequate work boots? Protect Your Workforce from the Ground Up

- What construction methods are used in high-quality engineer boots? A Guide to Boots That Last a Lifetime

- What type of sole is required for wildland fire boots? The Critical Safety Standard Explained

- How should engineer boots be paired with denim? A Guide to the Perfect Fit and Cuff