When it comes to high-quality engineer boots, the construction method is the foundation of their legendary durability. The most common and sought-after method is the Goodyear welt, a time-honored technique that involves stitching a leather strip (the welt) to the upper and the insole, and then stitching the outsole to that welt. This creates a highly durable, water-resistant, and, most importantly, resoleable boot designed to last for many years.

The construction method is the single most critical factor determining an engineer boot's longevity, repairability, and long-term value. While less expensive methods exist, the Goodyear welt is the undisputed hallmark of a premium boot built for a lifetime of wear.

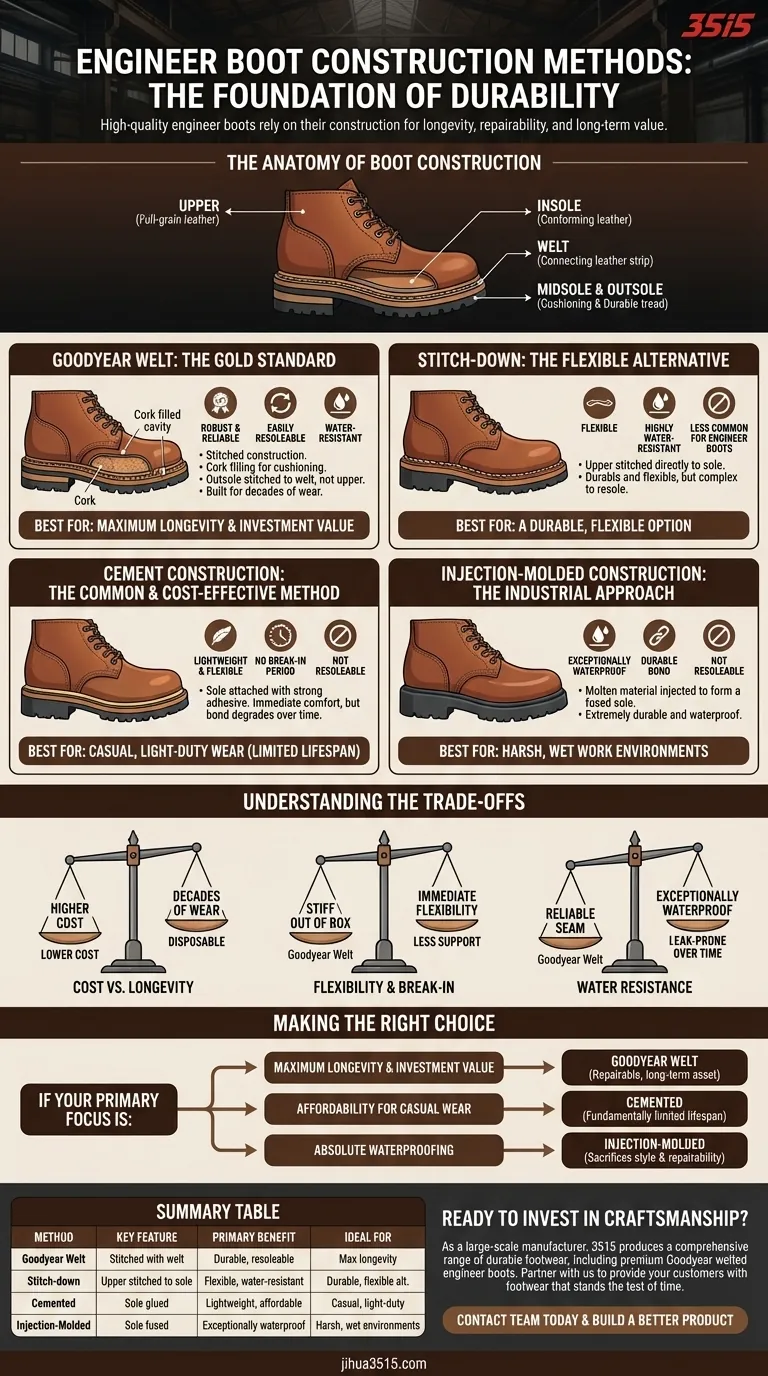

The Anatomy of Boot Construction

To understand the methods, it's essential to know the key components they bring together. A boot isn't just a single piece of leather, but a system of layers working in unison.

The Upper

This is the main body of the boot that you see, typically crafted from premium full-grain leather in high-quality engineer boots. Its design includes the tall shaft and distinctive buckle system.

The Insole

This is the layer directly beneath your foot. In premium boots, this is often a sturdy piece of leather that gradually conforms to the shape of your foot, creating a custom fit over time.

The Welt

In welted construction, the welt is a critical intermediary. It's a strip of leather that runs along the perimeter of the outsole, acting as the connecting point between the upper and the sole.

The Midsole and Outsole

The midsole provides cushioning and support, while the outsole is the durable layer that makes contact with the ground. The material and tread pattern of the outsole are designed for specific uses, from urban wear to heavy-duty traction.

Primary Construction Methods: A Comparative Look

The way these components are joined together defines the boot's character, cost, and lifespan.

Goodyear Welt: The Gold Standard

The Goodyear welt is prized for its robust and reliable construction. The process creates a small cavity between the insole and midsole which is filled with cork, providing cushioning and breathability.

Its primary advantage is that the outsole is stitched to the welt, not directly to the upper. This allows a cobbler to easily remove the old sole and stitch on a new one without compromising the boot's structure.

Stitch-down Construction: The Flexible Alternative

In this method, the leather of the upper is turned outward at the bottom and stitched directly to the midsole and outsole. This creates a very flexible and often highly water-resistant boot.

While also a high-quality method, it is less common for traditional engineer boots and can be more complex to resole than a Goodyear welt.

Cement Construction: The Common & Cost-Effective Method

This is the simplest and most common method used in footwear today. The sole is attached to the upper using a strong adhesive or cement.

This process results in a lightweight and flexible boot with no break-in period. However, the bond can degrade over time, and the boots are generally not designed to be resoled, making them a less durable option.

Injection-Molded Construction: The Industrial Approach

Primarily used for work and rain boots, this method involves placing the upper on a mold and injecting molten plastic or rubber to form a sole that is permanently fused to it.

This creates an exceptionally waterproof and durable bond. However, it completely eliminates the possibility of resoling and is not typically used for heritage-style engineer boots where craftsmanship and repairability are valued.

Understanding the Trade-offs

Choosing a boot means balancing cost, comfort, and longevity. The construction method is at the heart of these compromises.

Cost vs. Longevity

Goodyear welted boots have a significantly higher upfront cost due to the skilled labor and materials involved. However, their ability to be resoled multiple times means they can last for decades, offering superior long-term value. Cemented boots are far more affordable but are essentially disposable once the sole wears out.

Flexibility and Break-in Period

A Goodyear welted boot is often stiff out of the box. The robust leather insole and cork filling require a break-in period to soften and mold to your foot. In contrast, cemented boots offer immediate, sneaker-like flexibility and comfort.

Water Resistance

The lockstitch used in a Goodyear welt creates a very reliable, water-resistant seam. Injection molding creates the most waterproof seal, while cemented boots can be vulnerable to leaks as the adhesive ages and fails.

Making the Right Choice for Your Goal

Your intended use for the boots should guide your decision on which construction method to prioritize.

- If your primary focus is maximum longevity and investment value: Goodyear welt construction is the only choice, as it ensures the boots are a repairable, long-term asset.

- If your primary focus is affordability for casual, light-duty wear: A cemented boot may suffice, but you must accept its fundamentally limited lifespan.

- If your primary focus is absolute waterproofing for a harsh work environment: Look for injection-molded work boots, though they sacrifice the traditional style and repairability of engineer boots.

Ultimately, understanding a boot's construction empowers you to invest in true craftsmanship that is built to endure.

Summary Table:

| Construction Method | Key Feature | Primary Benefit | Ideal For |

|---|---|---|---|

| Goodyear Welt | Stitched construction with a leather welt | Durable, water-resistant, and easily resoleable | Maximum longevity and investment value |

| Stitch-down | Upper stitched directly to the sole | Flexible and highly water-resistant | A durable, flexible alternative |

| Cemented | Sole glued to the upper | Lightweight, affordable, immediate comfort | Casual, light-duty wear (limited lifespan) |

| Injection-Molded | Sole fused to the upper | Exceptionally waterproof and durable | Harsh, wet work environments (not resoleable) |

Ready to invest in boots built to last?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including premium Goodyear welted engineer boots designed for superior longevity and value.

Partner with us to provide your customers with footwear that stands the test of time.

Contact our team today to discuss your manufacturing needs and discover how we can help you build a better product.

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?

- What are heavy duty work boots designed for? Maximum Protection for Hazardous Work Environments

- Why is heat-resistant protective footwear required for high-temp construction? Essential Safety for Steam Pipe Ops

- What are penetration-resistant insoles in safety footwear? Steel vs. Textile for Ultimate Protection

- What is the significance of providing standardized steel-toed safety shoes? Enhance Occupational Health Research Accuracy