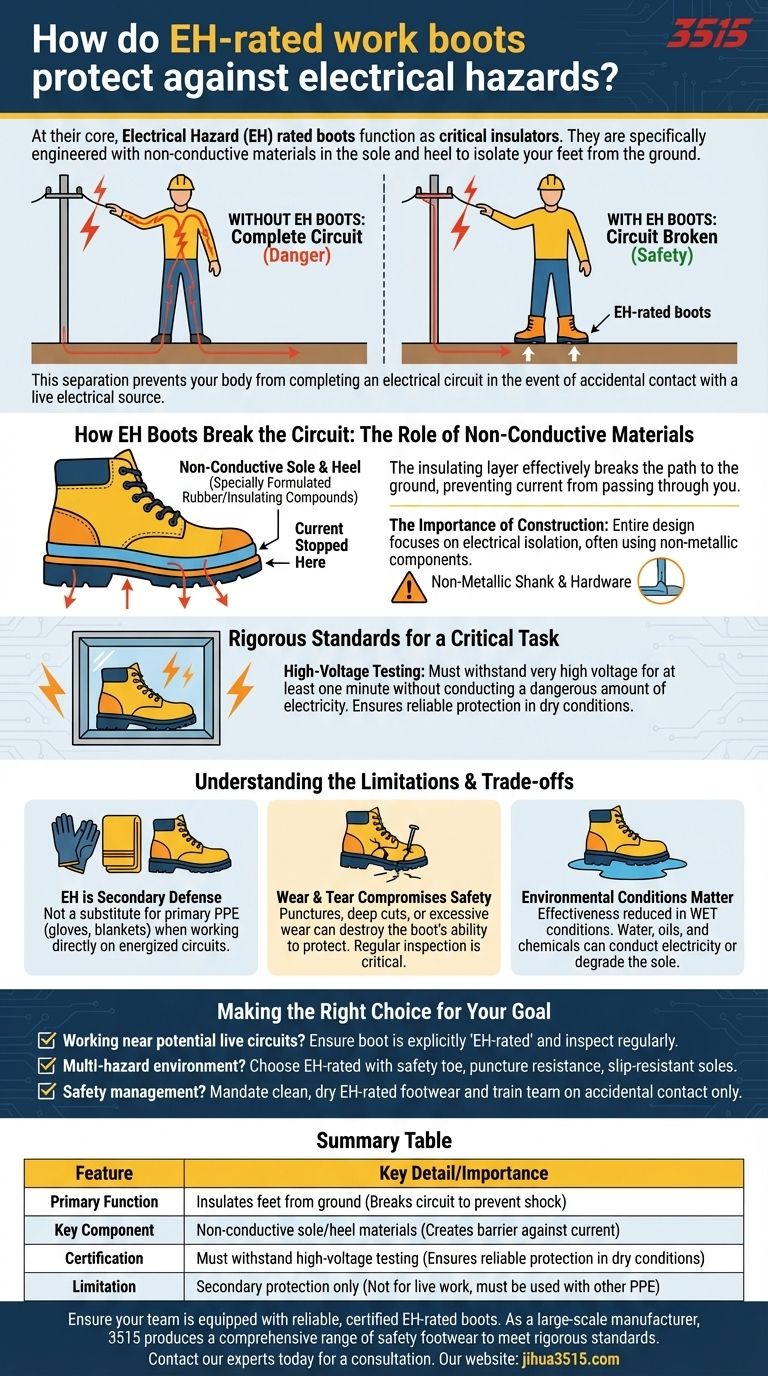

At their core, Electrical Hazard (EH) rated boots function as critical insulators. They are specifically engineered with non-conductive materials in the sole and heel to isolate your feet from the ground. This separation prevents your body from completing an electrical circuit in the event of accidental contact with a live electrical source, significantly reducing the risk of a dangerous or fatal shock.

The primary function of an EH-rated boot is not to allow you to work on live circuits, but to serve as a secondary, life-saving source of protection against accidental contact with energized equipment in dry conditions.

How EH Boots Break the Electrical Circuit

To understand how EH boots work, you must first understand how an electric shock occurs. For electricity to flow through your body, you must become part of a complete circuit—touching a live source with one part of your body and a path to the ground with another.

The Role of Non-Conductive Materials

EH-rated boots are constructed with soles and heels made from materials that do not conduct electricity, such as specially formulated rubber and other insulating compounds.

This insulating layer effectively breaks the path to the ground. If you accidentally step on a live wire, the boot's sole prevents the current from passing through you and into the earth, stopping the flow of electricity.

The Importance of Construction

The entire design is focused on electrical isolation. This often includes using non-metallic components throughout the boot where possible to minimize any potential for conductivity.

This feature is vital in situations where contact with live voltage is a risk, providing a crucial buffer that can prevent a serious incident.

Rigorous Standards for a Critical Task

EH-rated footwear is not just made from the right materials; it must pass stringent safety tests to earn its rating.

High-Voltage Testing

These boots undergo a rigorous testing process to confirm their protective capabilities. They are required to withstand a very high voltage for at least one minute without conducting a dangerous amount of electricity.

This certification ensures the footwear provides reliable protection under specific hazardous conditions, giving the wearer confidence in their equipment.

Protection Across Industries

This level of protection is essential for anyone working in fields where electrical hazards are present, from electricians and utility workers to maintenance staff in industrial settings.

EH-rated boots are a fundamental piece of personal protective equipment (PPE) for workers in heavy electrical and mining industries, among others.

Understanding the Limitations and Trade-offs

While EH boots are a life-saving technology, it is crucial to recognize their limitations. Over-reliance or improper use can create a false sense of security.

EH Boots are a Secondary Defense

EH-rated footwear is considered a secondary source of protection. It is not a substitute for primary protective equipment like insulated gloves, blankets, or proper lockout/tagout procedures when working directly on energized circuits.

Wear and Tear Compromises Safety

The insulating properties of the sole can be compromised by wear and tear. Punctures from nails, deep cuts, or excessive wear can destroy the boot's ability to protect you from shock. Regular inspection is critical.

Environmental Conditions Matter

The effectiveness of EH boots is significantly reduced in wet conditions. Water is a conductor of electricity and can negate the insulating properties of your footwear. Likewise, contamination with oils or certain chemicals can degrade the sole and compromise its integrity.

Making the Right Choice for Your Goal

Selecting the correct boot requires understanding your specific work environment and the hazards you face.

- If your primary focus is working near potential live circuits: Ensure your boot is explicitly "EH-rated" and inspect it regularly for damage, especially to the sole.

- If your primary focus is a multi-hazard environment: Choose an EH-rated boot that also includes other critical safety features like a safety toe, puncture resistance, and slip-resistant soles.

- If your primary focus is safety management: Mandate that all EH-rated footwear be kept clean and dry, and train your team to understand these boots are for accidental contact only.

Ultimately, viewing your EH-rated boots as a critical but secondary tool is the key to ensuring your safety around electrical hazards.

Summary Table:

| Feature | Key Detail | Importance |

|---|---|---|

| Primary Function | Insulates feet from the ground | Breaks the electrical circuit to prevent shock |

| Key Component | Non-conductive sole and heel materials | Creates a barrier against electrical current |

| Certification | Must withstand high-voltage testing | Ensures reliable protection in dry conditions |

| Limitation | Secondary protection only; not for live work | Must be used with other PPE and safe work practices |

Ensure your team is equipped with reliable, certified EH-rated boots. As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of EH-rated shoes and boots, designed to meet rigorous safety standards. Let us help you protect your workforce from electrical hazards. Contact our experts today for a consultation and discover the right safety solution for your needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What are some advanced technologies used in oilfield boots? Discover the Systems Protecting Workers

- Where can you purchase waterproofing products for leather boots? A Guide to Finding and Applying the Right Product

- What materials are used for work boot outsoles? Choose the Right Material for Your Job

- What are the recommended work boot features for the construction industry? Maximize Safety and Comfort

- What safety standards should oilfield work boots meet? Ensure OSHA & ASTM F2413 Compliance

- How are women's work boots designed differently? Engineered for a Woman's Foot Anatomy

- Are Moc toe boots still in fashion? Invest in a Timeless Workwear Staple

- What makes PVC work boots a cost-effective option? Essential Protection at an Unbeatable Price