At its core, an electrical hazard (EH) rated boot works by insulating you from the ground. Its sole and heel are constructed from special non-conductive materials, like rubber, which act as a barrier. If you accidentally step on a live electrical circuit, this barrier is designed to stop the current from traveling through your body to the ground, significantly reducing the risk of electrocution.

The primary function of an EH-rated boot is not to conduct electricity away, but to stop it completely. It turns the wearer into an isolated element, preventing the formation of a dangerous electrical circuit through their body.

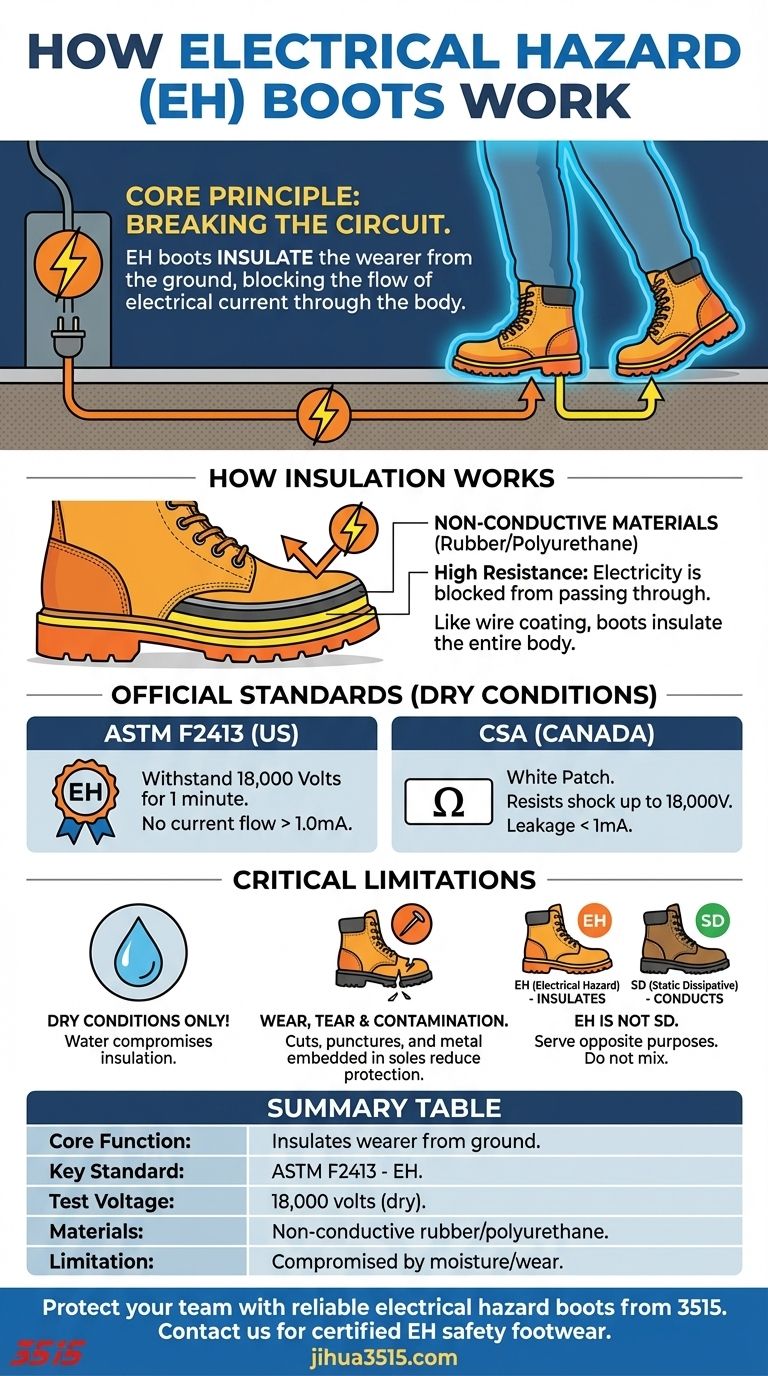

The Core Principle: Breaking the Circuit

An electrical current requires a complete path, or circuit, to flow. In an accidental electrocution scenario involving ground contact, the human body can become part of that circuit. EH boots are engineered specifically to break this dangerous connection.

How Insulation Works

Electricity always seeks the path of least resistance to the ground. The materials used in EH boot soles offer extremely high electrical resistance.

This high resistance makes it incredibly difficult for electricity to pass through the boot. The current is effectively blocked, preventing the circuit from being completed through your body.

Think of it like the rubber or plastic coating on an electrical wire. The coating insulates the conductive metal inside, allowing you to handle the wire safely. An EH boot provides a similar insulating layer for your entire body.

The Role of Non-Conductive Materials

The effectiveness of EH protection hinges entirely on the materials used. The outsole and heel are the most critical components.

These parts are typically made from rubber or specific polyurethane compounds formulated to be non-conductive. Critically, the construction of an EH-rated boot must also ensure no conductive materials (like nails or metal shanks) connect the outsole to the inside of the boot.

Understanding the Official Standards

To be considered genuine EH protective footwear, boots must be tested and certified to meet strict industry standards. This certification is your assurance that the footwear performs as designed.

The ASTM F2413 Standard

In the United States, the primary standard is ASTM F2413. Footwear that meets this standard is labeled "EH".

This certification means the boot has been tested to withstand the application of 18,000 volts at 60 Hz for one minute with no current flow or leakage current in excess of 1.0 milliampere under dry conditions.

The CSA White Omega Patch

In Canada, the standard is set by the Canadian Standards Association (CSA). EH-rated boots are identified by a distinct symbol.

Look for a white rectangle patch with an orange Greek letter omega (Ω) on the boot's upper. This signifies the soles provide resistance to electric shock up to 18,000 volts, with a leakage current not exceeding 1mA.

Critical Limitations and Trade-offs

Understanding what EH boots cannot do is just as important as knowing what they can. This is a secondary source of protection and not a license to disregard primary electrical safety protocols.

The "Dry Conditions" Caveat

The ASTM and CSA test standards are performed under dry conditions. This is a critical factor.

Water is a conductor of electricity. If your boots become wet, or you are standing in water, their insulating properties can be severely compromised or eliminated entirely.

Wear, Tear, and Contamination

The protective barrier of your boot is only as good as its condition. Deep cuts, punctures, or excessive wear can destroy the sole's insulating capabilities.

Furthermore, if the soles become embedded with conductive materials like metal shavings or screws, they can create a pathway for electricity, rendering the EH protection useless. Regular inspection of your footwear is essential.

EH is Not Static Dissipative (SD)

EH boots should not be confused with Static Dissipative (SD) footwear. They serve opposite purposes.

EH boots insulate you to prevent current flow. SD boots are designed to safely conduct static electricity to the ground to protect sensitive electronic equipment. Wearing EH boots in an environment that requires SD protection can be dangerous.

Making the Right Choice for Your Job

Selecting the proper footwear depends on a clear understanding of your work environment's specific electrical hazards.

- If your primary focus is working near live circuits: You need footwear explicitly marked with EH (ASTM F2413) or the CSA Omega symbol to ensure insulation from ground-based electrical shock.

- If your primary focus is preventing static buildup: You need footwear marked SD (Static Dissipative) to protect sensitive electronics, not EH boots.

- If you work in wet or compromised environments: You must recognize that EH boots offer reduced protection and should rely on primary safety measures like de-energizing circuits.

Ultimately, your safety relies on using EH footwear as a crucial secondary defense in a comprehensive electrical safety program.

Summary Table:

| Feature | Details |

|---|---|

| Core Function | Insulates the wearer from the ground to prevent electrical current flow. |

| Key Standard (ASTM) | ASTM F2413 - EH rating. |

| Test Voltage | 18,000 volts for 1 minute (dry conditions). |

| Critical Materials | Non-conductive rubber or polyurethane soles. |

| Primary Limitation | Protection can be compromised by moisture, wear, or damage. |

Protect your team with reliable electrical hazard boots from 3515. As a large-scale manufacturer, we produce a comprehensive range of certified EH safety footwear for distributors, brand owners, and bulk clients. Our boots are engineered to meet strict safety standards, providing the critical insulation your workers need. Contact us today to discuss your requirements and ensure your workforce is properly equipped.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- How do composite toe work boots provide protection without the weight of steel? Achieve Lighter, Safer Footwear

- What additional standards apply to proximity and structural firefighting footwear under NFPA 1971? Complete Hazard Protection Explained

- What was the common practice regarding boot maintenance in certain career fields? A Pragmatic Two-Boot System

- What should workers prioritize when selecting work boots for their industry? Match Boots to Hazards for Ultimate Safety

- What misconceptions exist about the origin of engineer boots? Uncover the True Marketing Story

- What additional features do quality wildfire boots offer besides heat protection? Ensure Stability and Protection on the Fire Line

- What are the common foot issues workers face due to uncomfortable work boots? Prevent Pain & Deformities

- What activities are packer boots suitable for? The Ultimate Hybrid Boot for Riding and Work