The mandated sole for wildland fire boots is a melt-resistant, rubber lug sole, commonly known as a Vibram-type sole. This specific construction is a non-negotiable safety requirement designed to provide critical traction and prevent catastrophic failure in high-heat environments.

The choice of a boot sole is not about brand preference; it is a critical safety decision. A standard boot sole can melt when exposed to the intense ground heat of a wildfire, leading to equipment failure, loss of traction, and severe injury.

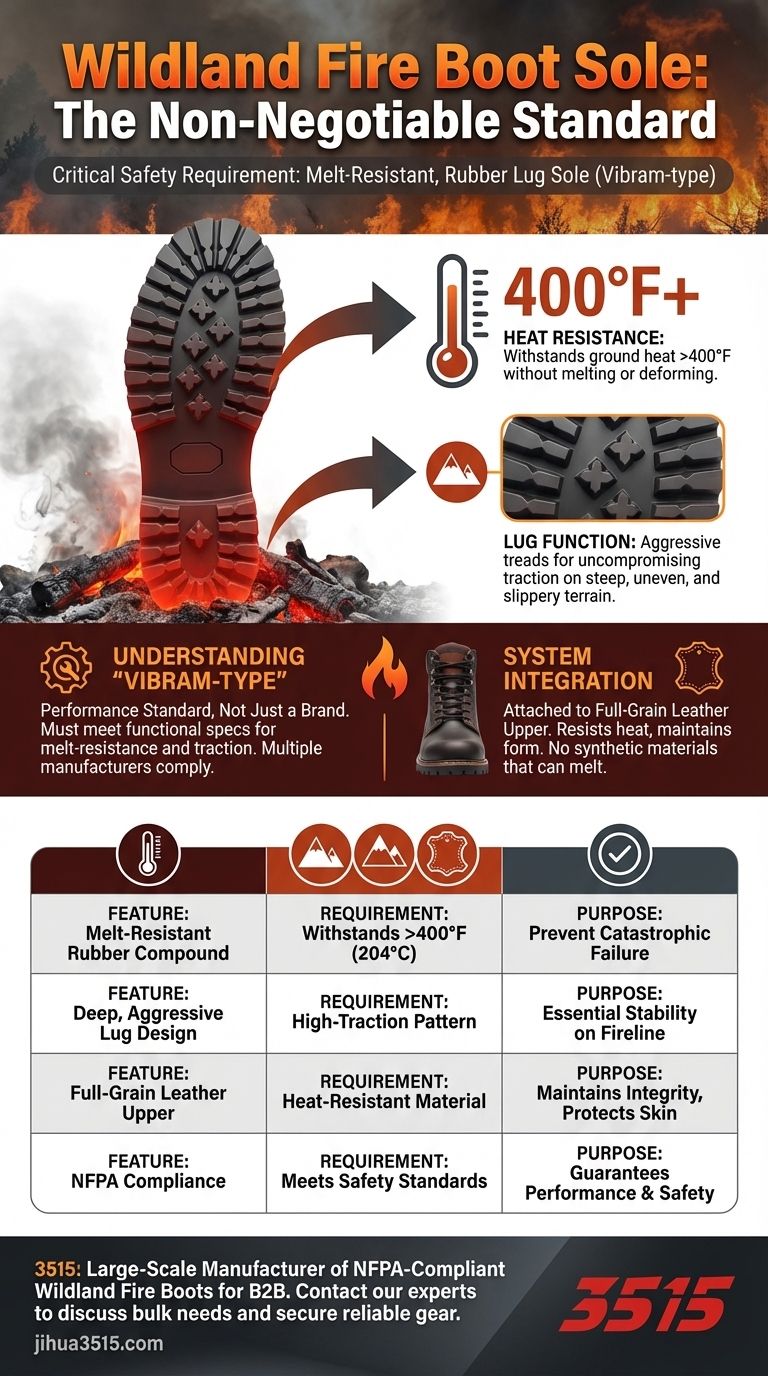

Why This Specific Sole is Non-Negotiable

A wildland firefighter's boots are a primary line of defense. The sole is arguably the most critical component, as it is in direct and constant contact with the hazardous ground of the fireline.

The Critical Role of Heat Resistance

The defining characteristic of a compliant sole is its resistance to melting. Wildland firefighters routinely walk on superheated ground, ash pits, and smoldering embers.

A standard hiking or work boot sole would quickly soften, deform, or even liquify under these conditions.

Compliant soles are made from a custom rubber compound, like the Vibram Red X Fire Lug, that can withstand temperatures exceeding 400 degrees Fahrenheit without losing its structural integrity.

The Function of a Lug Sole

Beyond heat, the terrain itself is a significant hazard. A "lug" design refers to the deep, aggressive treads on the bottom of the sole.

These lugs are essential for providing uncompromising traction on steep, uneven, muddy, or chemically slick ground, which is common in wildland environments. This stability is crucial for preventing slips and falls that can be catastrophic on a fireline.

How it Integrates with the Boot

This specialized sole is part of a larger safety system. It is attached to an upper made entirely of leather, which is required because it resists heat and maintains its form, unlike synthetic materials that can melt onto the skin.

The combination of a melt-resistant sole and a durable leather upper creates a boot capable of withstanding the extreme demands of the job.

Understanding the "Vibram-Type" Standard

The term "Vibram-type" can cause confusion. It's important to understand what it means in the context of safety regulations and equipment choice.

It's a Specification, Not Just a Brand

While Vibram is a well-known manufacturer that produces compliant soles, the term "Vibram-type" refers to a performance standard, not just a single brand.

The requirement dictates that the sole must be a melt-resistant rubber lug sole that meets the functional specifications for wildland firefighting. Other manufacturers can and do produce soles that meet this standard.

A Note on Regional Exemptions

Regulations can have specific exceptions. For example, Alaskan wildland firefighters are noted to be exempt from the requirement to have a Vibram-type sole.

This highlights the importance of always verifying the specific requirements mandated by your hiring agency or jurisdiction, as rare exceptions may apply.

Making the Right Choice for the Fireline

When selecting your boots, the sole should be a primary point of verification.

- If your primary focus is meeting federal and state requirements: You must select a boot explicitly advertised with a melt-resistant, Vibram-type lug sole that meets or exceeds NFPA standards.

- If your primary focus is safety and performance: Prioritize soles made from high-temperature compounds, as this ensures the boot will not fail when exposed to hot ground, ash pits, or embers.

- If you are purchasing for a specific region: Always verify local or agency-specific requirements, as rare exemptions like the one for Alaska do exist.

Ensuring your boot has the correct sole is a foundational step in guaranteeing your safety and effectiveness on the fireline.

Summary Table:

| Feature | Requirement | Purpose |

|---|---|---|

| Material | Melt-resistant rubber compound (e.g., Vibram-type) | Withstands ground heat exceeding 400°F (204°C) without deforming. |

| Design | Deep, aggressive lug pattern | Provides essential traction on steep, uneven, and slippery terrain. |

| Upper Material | Full-grain leather | Resists heat and maintains integrity, unlike synthetic materials. |

Ensure your team is equipped with NFPA-compliant safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of certified wildland fire boots for distributors, brand owners, and bulk clients. Our production capabilities ensure durable, high-performance boots that meet the strictest safety standards. Contact our experts today to discuss your specific needs and secure reliable gear for the fireline.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What are PVC work boots and how are they made? Your Guide to Durable, Waterproof Footwear

- Which professions commonly use western work boots? From Ranchers to Electricians

- What are winterized work boots and their features? Essential Footwear for Cold, Hazardous Job Sites

- What role does a slip-resistant outsole play in firefighter boots? Ensuring Critical Traction and Safety

- What are the steps for maintaining and storing lace-up boots? A Guide to Extend Their Lifespan

- What is a recommended color for work boots? Discover the Best Choice for Durability & Professionalism

- What are the recommended practices for cleaning work boots? A Guide to Extend Boot Life & Safety

- What design features should be considered for additional protection and convenience in work boots? Enhance Your Safety and Comfort