In short, composite toe boots are particularly advantageous in any work environment where electrical hazards, security checkpoints, or extreme temperatures are a primary concern. Their non-metallic and lightweight properties also make them a superior choice for workers who spend long hours on their feet and require maximum comfort and mobility.

The core advantage of composite toe boots is not just protection, but specialized protection. Their non-metallic properties solve modern workplace challenges that steel cannot, from passing through a metal detector to working safely around live circuits.

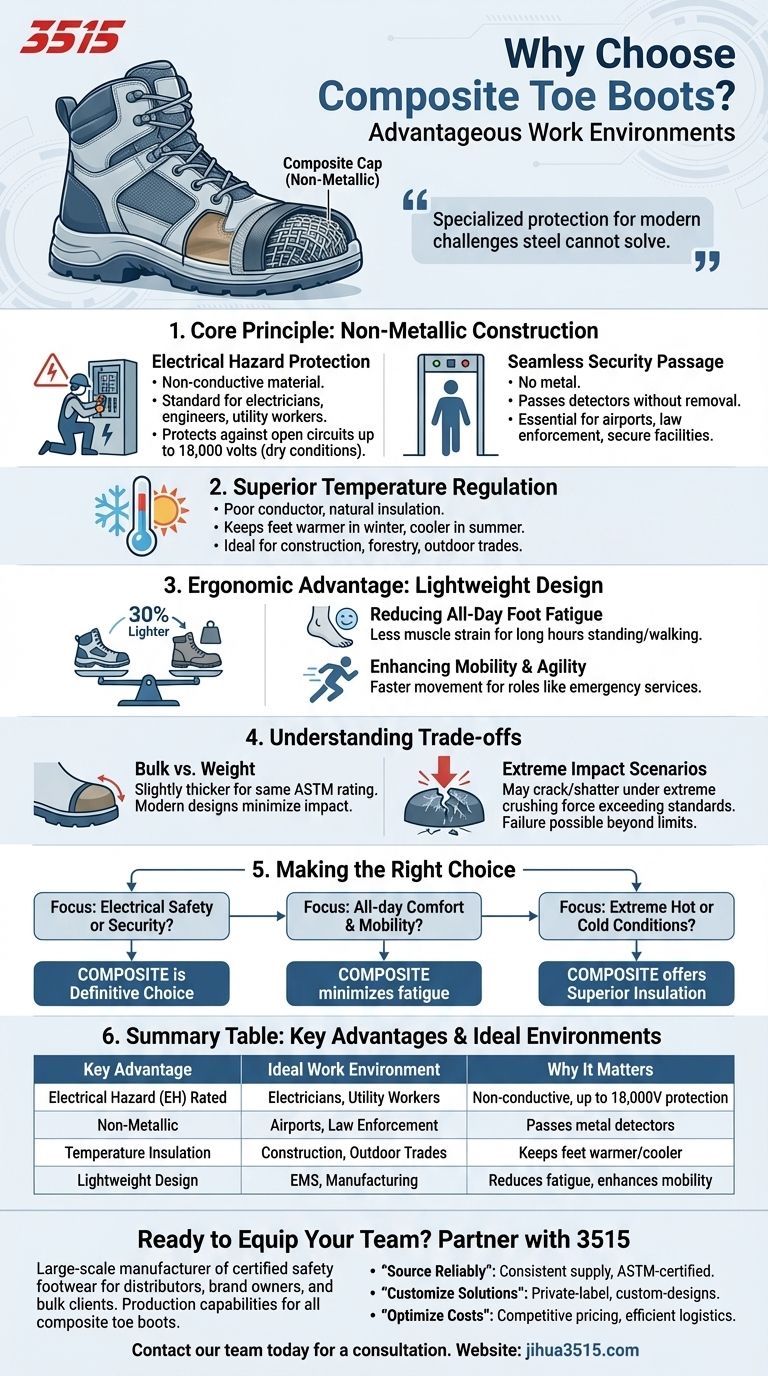

The Core Principle: Non-Metallic Construction

The fundamental difference between composite and steel toe boots is the material of the protective cap. Composite caps are made from non-metal materials like Kevlar, carbon fiber, or plastic. This single distinction is the source of their key advantages.

Electrical Hazard Protection

Because composite materials do not conduct electricity, these boots are the standard for electricians, engineers, and utility workers.

They provide a critical layer of defense against accidental contact with live circuits. Many models are rated to protect against open circuits of up to 18,000 volts in dry conditions, a level of safety steel toes cannot offer.

Seamless Passage Through Security

For anyone working in a secure facility that requires passing through metal detectors, composite toe boots are a practical necessity.

This includes airport staff, law enforcement, certain government contractors, and mobile workers who travel frequently. The non-metallic cap eliminates the daily hassle of removing footwear for security screenings.

Superior Temperature Regulation

Metal is an excellent thermal conductor, meaning steel toe caps get extremely cold in the winter and uncomfortably hot in the summer.

Composite materials are poor conductors, providing natural insulation. This makes the boots far more comfortable for anyone working outdoors in extreme weather, such as in forestry, construction, or other trades exposed to the elements.

The Ergonomic Advantage: Lightweight Design

Beyond safety from specific hazards, composite toe boots offer a significant benefit in comfort and long-term wellness, primarily due to their reduced weight.

Reducing All-Day Foot Fatigue

Composite toe caps are approximately 30% lighter than their steel counterparts. While this difference may seem small, it adds up over thousands of steps a day.

This weight reduction directly translates to less muscle strain and foot fatigue, making them ideal for any occupation that involves long hours of standing or walking.

Enhancing Mobility and Agility

For roles that demand quick movement, such as law enforcement or emergency services, a lighter boot enhances agility. Less weight on the feet allows for faster, more natural movement without sacrificing certified protection against impact and compression.

Understanding the Trade-offs

No single piece of equipment is perfect for every situation. To make an informed decision, it's critical to understand the compromises inherent in choosing a composite toe.

Bulk vs. Weight

To achieve the same ASTM safety rating for impact and compression, a composite toe cap must be slightly thicker and bulkier than a steel one.

For some, this can make the boot feel slightly larger at the tip or affect the overall aesthetic. However, most modern designs accommodate this difference with minimal impact on fit.

Extreme Impact Scenarios

Both steel and composite toe boots must pass the same rigorous ASTM certification tests. However, they behave differently under forces that exceed those standards.

Under an extreme crushing force beyond its rating, steel is more likely to bend, whereas a composite cap is more likely to crack or shatter. It is crucial to remember that in any scenario exceeding ASTM limits, a catastrophic failure of safety equipment is possible.

Making the Right Choice for Your Environment

Ultimately, selecting the right boot means aligning its properties with the primary demands of your job.

- If your primary focus is electrical safety or security clearance: Composite is the definitive choice due to its non-metallic, non-conductive properties.

- If your primary focus is all-day comfort and mobility: The significant weight reduction of composite toes makes them ideal for minimizing fatigue over long shifts.

- If your primary focus is working in extreme hot or cold conditions: Composite toe boots offer superior thermal insulation, keeping your feet significantly more comfortable than steel.

Choosing the right safety boot is about matching the material's inherent strengths to your specific daily hazards and demands.

Summary Table:

| Key Advantage | Ideal Work Environment | Why It Matters |

|---|---|---|

| Electrical Hazard (EH) Rated | Electricians, Utility Workers, Engineers | Non-conductive material protects against live circuits up to 18,000 volts. |

| Non-Metallic | Airports, Law Enforcement, Secure Facilities | Passes through metal detectors without setting them off. |

| Temperature Insulation | Construction, Forestry, Outdoor Trades | Keeps feet warmer in winter and cooler in summer than steel. |

| Lightweight Design | Roles with long hours standing/walking (e.g., EMS, Manufacturing) | Reduces foot fatigue and enhances mobility over a full shift. |

Ready to Equip Your Team with Superior Composite Toe Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of composite toe boots designed for the specific challenges of your industry.

We can help you:

- Source Reliably: Ensure a consistent supply of high-quality, ASTM-certified composite toe boots.

- Customize Solutions: Develop private-label or custom-designed boots tailored to your brand and your customers' unique needs.

- Optimize Costs: Benefit from competitive pricing and efficient logistics for bulk orders.

Let's discuss how we can support your business. Contact our team today for a consultation.

Visual Guide

Related Products

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium KPU Injection Athletic Style Safety Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- Why is melt- and flame-resistant thread important in firefighter boots? To Prevent Catastrophic Seam Failure

- What safety certifications should work boots have? Decode ASTM F2413 for Maximum Protection

- How can you ensure consistent comfort in work boots? Focus on Fit, Materials & Ergonomics

- When is it appropriate to use leather conditioner on boots? Identify the Signs of Dry Leather

- How do boots with ankle support enhance comfort? Achieve Stability and Reduce Fatigue

- What are the key characteristics of engineer boots? Discover the Anatomy of a Rugged Icon

- What are the key safety standards for work boots? Choose the Right Protection for Your Job

- What additional safety features might work boots have? Essential Protection for Your Job Site