The primary safety certification for work boots in the United States is ASTM F2413. This standard establishes the minimum requirements for the design, performance, testing, and classification of protective footwear. A boot that carries this certification has been independently tested to protect you from specific workplace hazards.

The key is to understand that ASTM F2413 is not a single rating, but a coding system. You must learn to read the boot's label to ensure its specific protections match the actual hazards you face on the job.

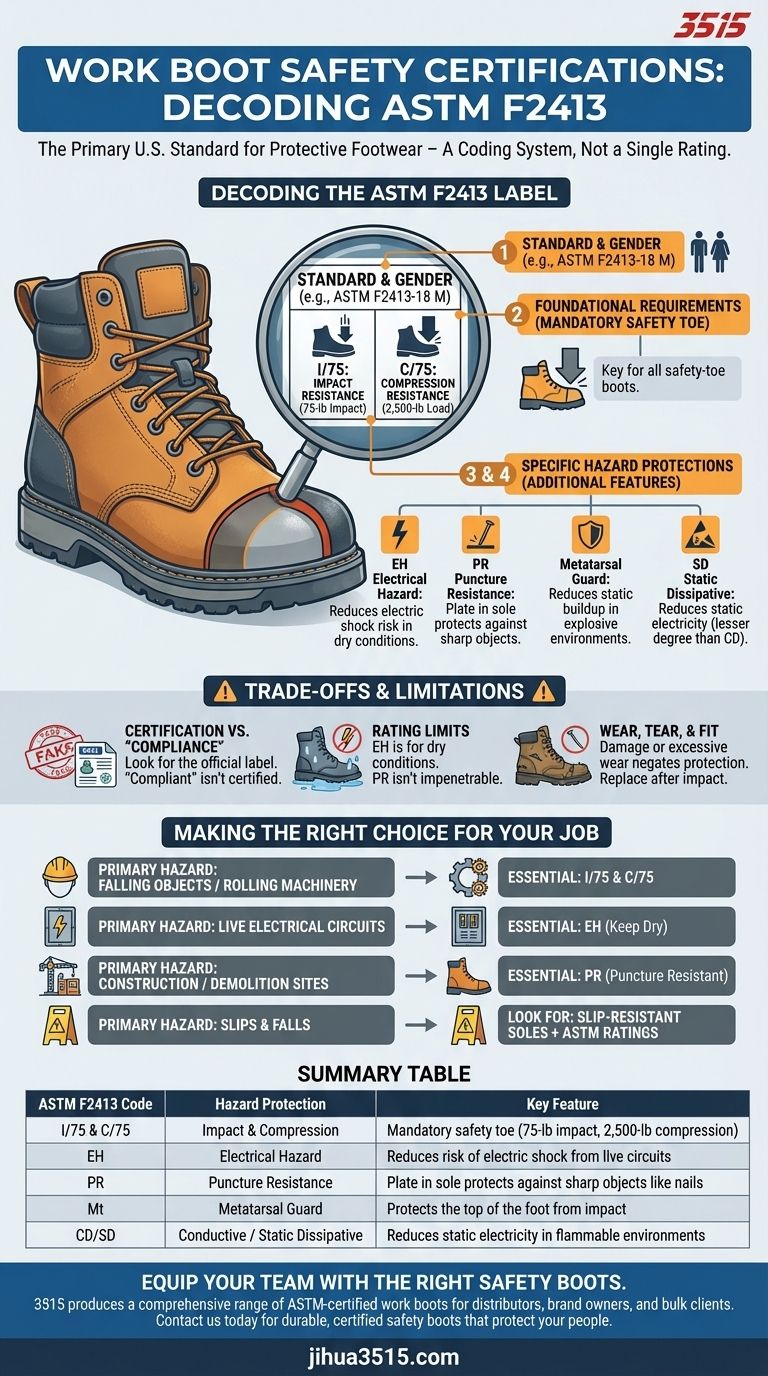

Decoding the ASTM F2413 Label

Every boot that meets the ASTM F2413 standard will have a specific label, typically sewn inside the tongue. This label is the definitive guide to its safety features. It is formatted with multiple lines, each identifying a specific protection.

Line 1: The Standard and Gender

The first line always identifies the standard (ASTM F2413) and the year of the standard it was tested against (e.g., -18 for the 2018 version). It will also indicate if the boot is designed for a Male (M) or Female (F) fit.

Line 2: The Foundational Requirements (I/C)

This is the most critical line. It confirms the boot's resistance to two primary hazards: impact and compression. These are mandatory for a boot to be considered a "safety-toe" boot under the standard.

- I/75: This indicates the toe cap's impact resistance. It can withstand a 75-pound impact.

- C/75: This indicates the toe cap's compression resistance. It can withstand a compressive load of 2,500 pounds.

Line 3 & 4: Protection from Specific Hazards

Subsequent lines denote any additional safety features the boot possesses. These are not mandatory for all boots but are critical for specific jobs, such as those performed by electricians, loggers, or construction workers.

- EH: Indicates Electrical Hazard protection. These boots have soles and heels designed to reduce the potential of electric shock when the sole is exposed to live electrical circuits.

- PR: Indicates Puncture Resistance. A plate is built into the sole to protect the foot from sharp objects like nails.

- Mt: Indicates a Metatarsal Guard. This provides added protection for the top of the foot against impact.

- CD: Indicates Conductive properties, which reduce the buildup of static electricity. This is crucial in highly flammable or explosive environments.

- SD: Indicates Static Dissipative properties, which also reduce static electricity but to a lesser degree than CD boots.

Understanding the Trade-offs and Limitations

Certification is the baseline for safety, but it isn't the entire story. Relying on the label alone without considering the context can lead to a false sense of security.

Certification vs. "Compliance"

Be wary of boots advertised as "ASTM compliant" or "meets ASTM standards" without an official label inside. True certification requires third-party lab testing. An uncertified boot has no guarantee of performance and can fail under stress.

The Limits of a Rating

An EH-rated boot provides protection only in dry conditions and can be compromised by wear or excessive moisture. Similarly, a puncture-resistant sole doesn't make the boot impenetrable—extreme force or sharp objects at odd angles can still pose a risk.

Wear, Tear, and Fit

The certification applies to the boot in its new condition. Deep cuts, punctures in the sole, or excessive wear can negate its protective features. A single, heavy impact to the safety toe means the boot must be replaced, as its structural integrity is now compromised.

Making the Right Choice for Your Job

Your goal is to match the boot's certified protections to the specific, predictable hazards of your worksite.

- If your primary focus is protection from falling objects or rolling machinery: Your non-negotiable requirement is the I/75 and C/75 rating.

- If your primary focus is working near live electrical circuits: You must select a boot with a clear EH rating and keep it in good, dry condition.

- If your primary focus is construction or demolition sites: A PR (Puncture Resistant) rating is essential to protect against nails and other sharp debris underfoot.

- If your primary focus is preventing slips and falls: Look for boots that specifically advertise high-traction, slip-resistant soles in addition to their core ASTM safety ratings.

Ultimately, understanding the language of safety certification empowers you to make an informed choice that directly protects you from harm.

Summary Table:

| ASTM F2413 Code | Hazard Protection | Key Feature |

|---|---|---|

| I/75 & C/75 | Impact & Compression | Mandatory safety toe (75-lb impact, 2,500-lb compression) |

| EH | Electrical Hazard | Reduces risk of electric shock from live circuits |

| PR | Puncture Resistance | Plate in sole protects against sharp objects like nails |

| Mt | Metatarsal Guard | Protects the top of the foot from impact |

| CD/SD | Conductive / Static Dissipative | Reduces static electricity in flammable environments |

Ensure your team is equipped with the right safety boots for the job. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified work boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, ensuring every pair meets the precise hazard protections your workforce needs. Contact us today for durable, certified safety boots that protect your most valuable asset—your people.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What additional safety equipment might be needed with work boots? Complete Your PPE System for Total Protection

- What is the origin of engineer boots? Born in the 1930s for Industrial Workers

- Why were traditional leather conditioners ineffective for firefighter boots? The Hidden Danger of Sealing vs. Breathing

- How do hot weather and cold weather boots differ? Choose the Right Boot for Any Climate

- What safety boots are recommended for the manufacturing industry? Ensure Complete Protection & Comfort

- What are cowboy boots and what do they represent? A Symbol of Rugged Independence and Style

- What was the common practice regarding boot maintenance in certain career fields? A Pragmatic Two-Boot System

- What is metatarsal guard protection in mining boots? Essential Safety for Heavy Industry