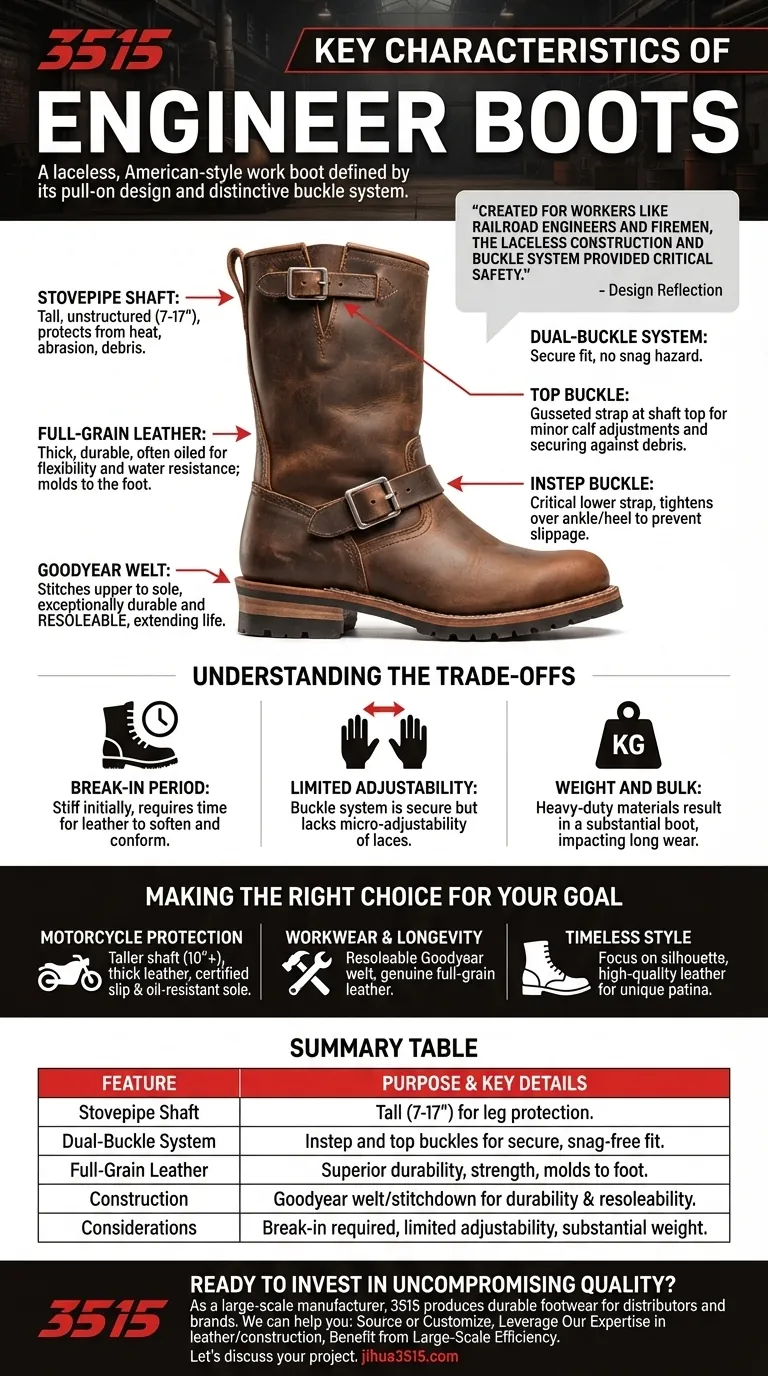

At its core, an engineer boot is a laceless, American-style work boot defined by its pull-on design and distinctive buckle system. It is characterized by a tall "stovepipe" shaft, a plain rounded toe, and two adjustable leather straps—one across the instep and another at the top of the shaft. This rugged construction prioritizes durability, protection, and a secure fit without the snag hazard of laces.

The design of the engineer boot is a direct reflection of its original purpose. Created for workers like railroad engineers and firemen, the laceless construction and buckle system provided critical safety, preventing entanglement in machinery while offering robust protection from heat and impact.

The Anatomy of an Engineer Boot

To truly understand the engineer boot, we must examine the functional purpose behind each of its core components. The design is a masterclass in utility, where every feature serves a specific need.

The Stovepipe Shaft

The tall, unstructured shaft, typically ranging from 7 to 17 inches, is the boot's most prominent feature. Its primary function is to protect the wearer's leg from heat, abrasion, and debris. This was essential for workers on steam locomotives and remains a key protective element for motorcyclists today.

The Dual-Buckle System

The lack of laces is intentional. The two-buckle system offers a secure fit without the risk of snagging.

- The Instep Buckle: This lower strap is the most critical for fit, allowing the wearer to tighten the boot over the ankle and heel to prevent slippage.

- The Top Buckle: This gusseted strap at the top of the shaft allows for minor adjustments to fit the calf, securing the boot and preventing debris from entering.

Full-Grain Leather Construction

True engineer boots are almost exclusively made from thick, durable full-grain leather, often in black or brown. This material is chosen for its superior strength and ability to mold to the wearer's foot over time. Many are made with oiled leather, which enhances flexibility and water resistance.

The Rugged Foundation

The boot's sole and construction method are fundamental to its longevity. High-quality engineer boots feature a Goodyear welt or a similar stitchdown construction. This technique stitches the upper to the sole, making the boot exceptionally durable and, most importantly, resoleable, dramatically extending its life.

Understanding the Trade-offs

While exceptionally durable, the engineer boot's design comes with practical considerations that every potential owner should understand.

The Break-in Period

The same thick, full-grain leather that provides protection and longevity also requires a significant break-in period. A new pair of high-quality engineer boots will be stiff and can be uncomfortable until the leather softens and conforms to your foot.

Limited Adjustability

The buckle system, while secure, does not offer the same micro-adjustability as a traditional lacing system. Achieving a perfect fit is crucial from the start, as there is less room for error compared to a fully laced boot.

Weight and Bulk

These are not lightweight boots. The heavy-duty leather, rugged soles, and durable construction result in a substantial boot. This weight is a testament to their protective qualities but can be a factor for all-day wear if you are unaccustomed to it.

Making the Right Choice for Your Goal

Selecting the right engineer boot depends entirely on your primary intended use.

- If your primary focus is motorcycle protection: Prioritize a taller shaft (10+ inches), thick leather, and a certified slip-resistant and oil-resistant sole.

- If your primary focus is workwear and longevity: Insist on a resoleable Goodyear welt construction and verify the use of genuine full-grain leather.

- If your primary focus is timeless style: Concentrate on the silhouette and the quality of the leather, as this will determine how well the boot ages and develops a unique patina.

Ultimately, choosing an engineer boot is an investment in uncompromising function and an iconic piece of American heritage.

Summary Table:

| Feature | Purpose & Key Details |

|---|---|

| Stovepipe Shaft | Tall (7-17") for leg protection from heat and debris. |

| Dual-Buckle System | Instep and top buckles for a secure, snag-free fit. |

| Full-Grain Leather | Provides superior durability, strength, and molds to the foot. |

| Construction | Goodyear welt or stitchdown for durability and resoleability. |

| Considerations | Requires a break-in period; limited adjustability; substantial weight. |

Ready to Invest in Uncompromising Quality?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of rugged boots, including authentic engineer boots built to the highest standards of protection and longevity.

We can help you:

- Source or Customize engineer boots with the exact specifications for your market.

- Leverage Our Expertise in full-grain leather and resoleable construction for superior products.

- Benefit from Large-Scale Efficiency without sacrificing quality.

Let's discuss your project. Contact our team today to get a quote or learn more about our manufacturing capabilities.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- In what work environments are soft-toe boots recommended? Ideal for Low-Risk Jobs Needing All-Day Comfort

- What are some ways to enhance an outfit with moc toe boots? Master Rugged, Smart-Casual & Modern Styles

- What are important considerations when selecting work shoes? Balance Safety, Comfort, and Durability

- What should workers prioritize when selecting work boots for their industry? Match Boots to Hazards for Ultimate Safety

- What are engineer boots and their characteristics? Unpacking the Iconic Work & Motorcycle Boot

- What are the main similarities between PVC, neoprene, and rubber work boots? The Key Waterproof Trait Explained

- Why is it important to select breathable and supportive materials for work boot uppers? Enhance Safety and Comfort

- How does slip resistance benefit firefighters? Secure Your Mission with Superior Grip