At its core, melt- and flame-resistant thread is critical in firefighter boots because it provides the structural integrity that holds the boot together under extreme heat. If the thread melts or burns away, the seams fail, the protective layers separate, and the boot completely loses its ability to shield the firefighter from life-threatening conditions.

The thread is not just a detail; it is the essential skeleton of the boot. Its primary purpose is to prevent catastrophic structural failure when exposed to fire, ensuring the boot remains a protective enclosure rather than falling apart at the most critical moment.

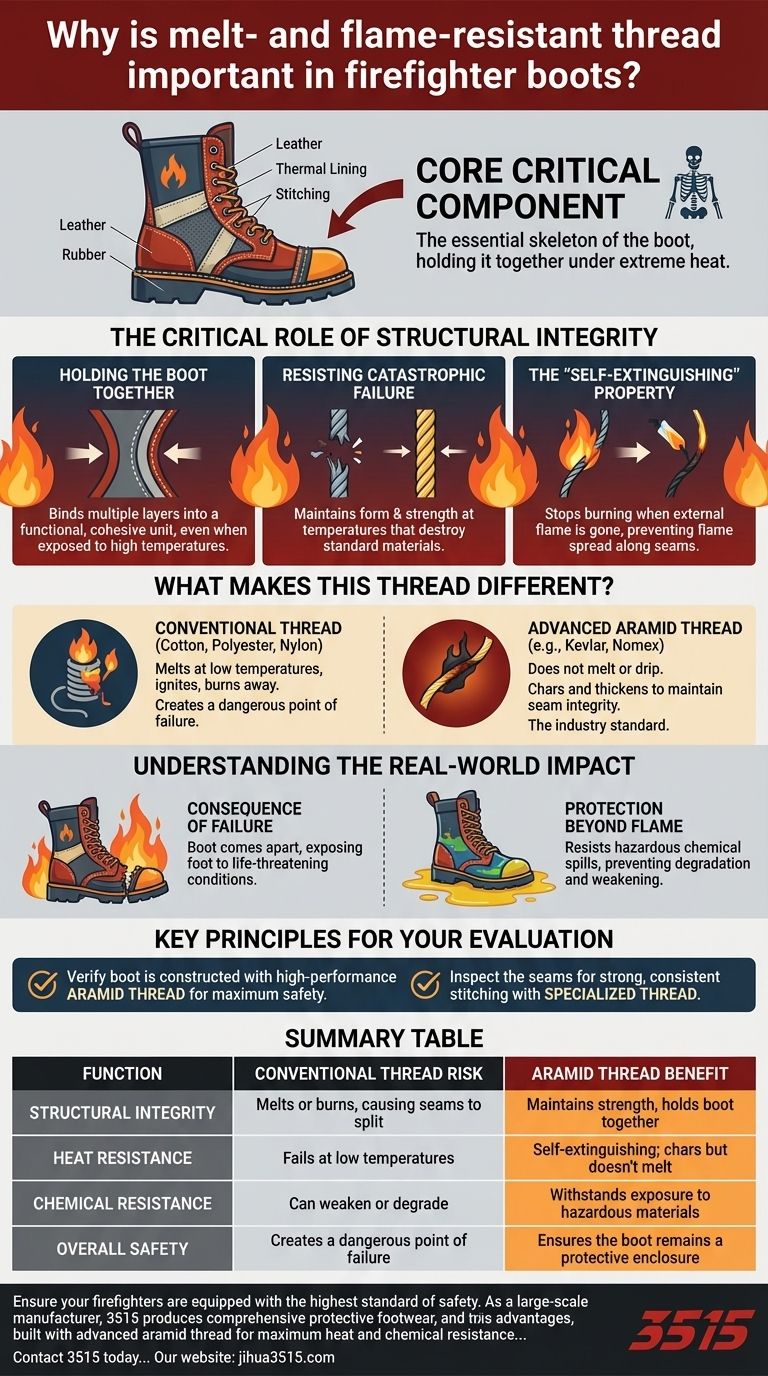

The Critical Role of Structural Integrity

A firefighter's boot is a complex assembly of multiple layers, each with a specific protective function. The thread is the single component that binds all these layers into a functional, cohesive unit.

Holding the Boot Together

The various pieces of leather, rubber, and thermal lining that make up a boot are joined by stitching. This stitching is under constant stress, but in a fire, that stress becomes extreme.

The melt- and flame-resistant thread ensures these seams remain intact, even when directly exposed to high temperatures and flames.

Resisting Catastrophic Failure

Standard threads, like cotton or conventional polyester, would disintegrate almost instantly in a fire. They would either burn away or melt into a liquid, causing the seams to split open.

Specialized thread is engineered to maintain its solid form and a high degree of its strength at temperatures that would destroy lesser materials.

The "Self-Extinguishing" Property

A key feature of this thread is that it is self-extinguishing. This means if it is ignited by a flame, it will stop burning as soon as the external flame source is removed.

This crucial property prevents the thread from acting like a fuse, carrying a flame along the seams and compromising the entire boot long after the initial exposure.

What Makes This Thread Different?

The performance of flame-resistant thread comes from its advanced material science. It is fundamentally different from the threads used in consumer clothing or standard work boots.

The Weakness of Conventional Materials

Threads made from natural fibers like cotton will ignite and burn. Standard synthetic threads like nylon or polyester will simply melt at relatively low temperatures, offering no protection.

Using these materials in a firefighter boot would create a dangerous, predetermined point of failure.

Advanced Aramid Fibers

Firefighter gear almost universally relies on thread made from aramid fibers. These are a class of high-performance synthetics known for exceptional heat resistance and strength.

Aramids do not melt or drip when exposed to intense heat. Instead, they char and thicken, which helps to maintain the seam's integrity and further seal out heat.

Understanding the Real-World Impact

The choice of thread is not an academic exercise; it has direct and immediate consequences for a firefighter's safety on the ground.

The Consequence of Thread Failure

If the stitching fails, the boot can come apart. This exposes the foot directly to flames, superheated water, steam, or hazardous chemicals.

A structural failure of the boot effectively removes the firefighter's last line of defense against severe burns and chemical injuries to the feet.

Protection Beyond Flame

The references correctly note that this thread also resists chemicals. In many emergency situations, firefighters face spills of corrosive or hazardous materials.

A thread that maintains its integrity when exposed to these substances is just as important as one that resists heat, preventing the boot from weakening or coming apart due to chemical attack.

Key Principles for Your Evaluation

When assessing protective footwear, the quality of the stitching is a direct indicator of its reliability under duress.

- If your primary focus is maximum safety: Verify that the boot is constructed with high-performance aramid thread, as this is the industry standard for resisting catastrophic heat failure.

- If your primary focus is understanding gear integrity: Always look past the primary materials and inspect the seams. Strong, consistent stitching with specialized thread is the hallmark of a boot built for true high-risk environments.

Ultimately, a piece of protective equipment is only as strong as its most vulnerable component.

Summary Table:

| Function | Conventional Thread Risk | Aramid Thread Benefit |

|---|---|---|

| Structural Integrity | Melts or burns, causing seams to split | Maintains strength, holds boot together |

| Heat Resistance | Fails at low temperatures | Self-extinguishing; chars but doesn't melt |

| Chemical Resistance | Can weaken or degrade | Withstands exposure to hazardous materials |

| Overall Safety | Creates a dangerous point of failure | Ensures the boot remains a protective enclosure |

Ensure your firefighters are equipped with the highest standard of safety.

As a large-scale manufacturer, 3515 produces comprehensive protective footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots, including those built with advanced aramid thread for maximum heat and chemical resistance, ensuring complete gear integrity.

Contact 3515 today to discuss your high-performance footwear needs and secure reliable protection.

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- How can firefighters maintain their leather boots effectively? Ensure Long-Lasting Protection and Comfort

- What are the benefits of work boots for women? Safety, Comfort & Durability Explained

- What role does grip and traction play in farming and gardening boots? Ensure Safety and Stability on Any Terrain

- Why are slip-resistant soles important in work boots? Prevent Slips & Boost Safety

- What are the construction-specific OSHA footwear requirements? Choose the Right Boots for Job Site Safety

- What are the advantages of using PU for work boots? Lightweight Comfort & Durability Explained

- How do work boots impact the physiological heat load of laborers? Understanding Heat Stress in High Temperatures

- What are the main features that define a good work boot? Essential Guide to Safety & Comfort