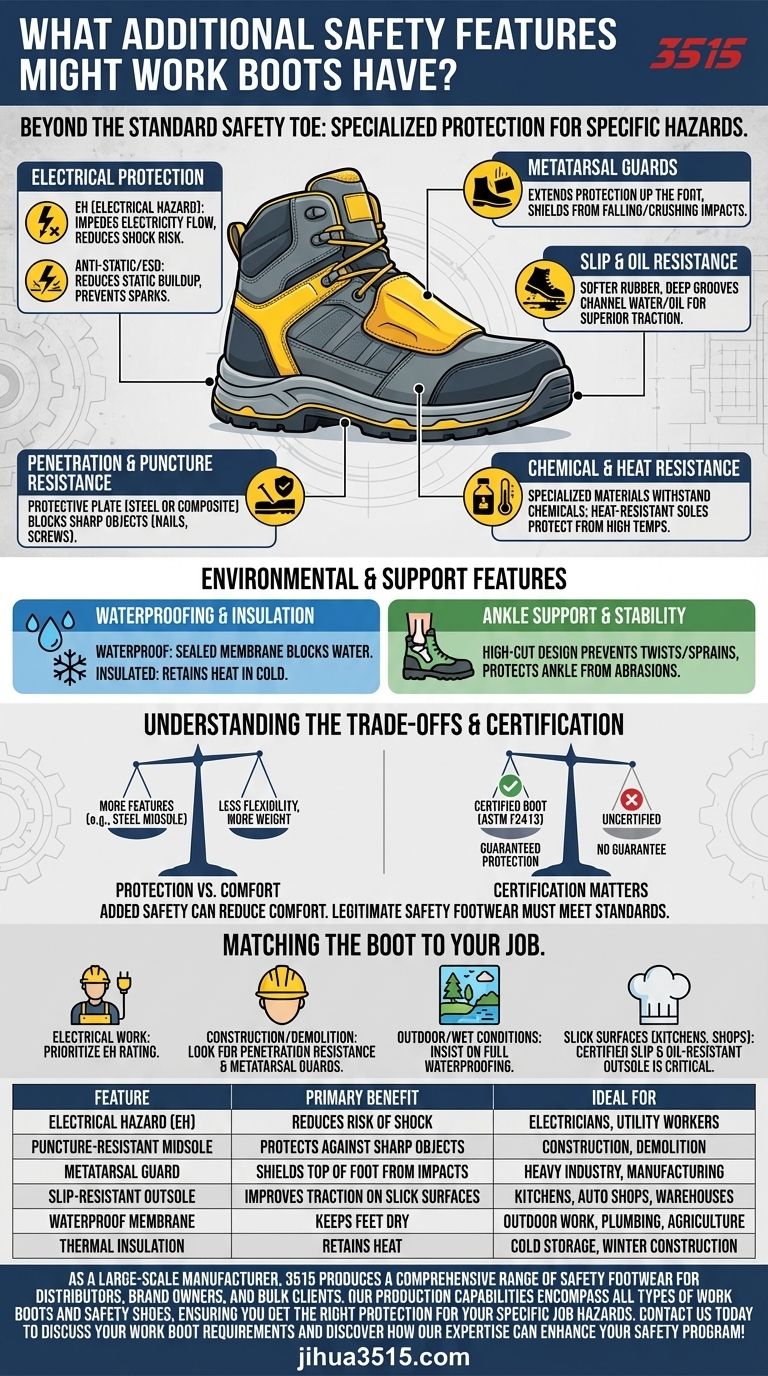

Beyond the standard safety toe, modern work boots offer a wide range of specialized features designed to protect against specific workplace hazards. These additions include protection from electrical currents, puncture-resistant soles to guard against sharp objects, slip-resistant outsoles for superior traction, metatarsal guards for top-of-foot impact, and waterproofing for environmental control.

The most effective work boot is not the one with the most features, but the one with the right features for your specific job hazards. Understanding these additional protections is crucial for matching your footwear to your work environment.

Protection from Specific Workplace Hazards

A boot's true value is determined by how well it mitigates the risks you face daily. The most critical features are those that directly counter a known hazard.

Electrical Protection (EH vs. Anti-Static)

Many job sites have electrical risks. Boots can offer two distinct types of protection.

Electrical Hazard (EH) rated boots are designed to impede the flow of electricity, reducing the chance of shock from accidental contact with live electrical circuits.

Anti-Static or Electrostatic Dissipative (ESD) boots do the opposite. They reduce the buildup of static electricity on your body, which is critical in environments where a static spark could damage sensitive electronics or ignite flammable materials.

Penetration and Puncture Resistance

Standard outsoles offer no protection from nails, screws, or other sharp objects on the ground.

Puncture-resistant boots incorporate a protective plate—made of steel or a flexible composite material—into the midsole, directly beneath your foot, to block sharp objects from penetrating the boot.

Metatarsal Guards

A standard safety toe only protects the tips of your toes from compression and impact.

Metatarsal guards extend this protection up the top of your foot (the metatarsal area), shielding it from falling objects or crushing injuries that could strike behind the toe cap.

Slip and Oil Resistance

Slips, trips, and falls are among the most common workplace accidents.

Slip-resistant outsoles are made from softer rubber compounds and feature specialized tread patterns with deep grooves designed to channel away water and oil, maximizing the sole’s contact with the ground for better traction.

Chemical and Heat Resistance

For specialized industries, standard leather or synthetic materials are not enough.

Chemical-resistant boots use materials specifically engineered to withstand degradation from exposure to certain chemicals. Similarly, heat-resistant soles protect against contact with high-temperature surfaces.

Environmental and Support Features

Beyond immediate impact or puncture hazards, boots must often perform in challenging environments while supporting the wearer through a long day.

Waterproofing vs. Water Resistance

These terms are not interchangeable. Water-resistant materials can shed light moisture but will eventually soak through.

A waterproof boot features a sealed inner membrane or bootie that completely blocks water from entering, keeping your feet dry in rain, puddles, or other wet conditions.

Thermal Insulation

Working in cold climates requires protection against the elements to prevent frostbite and maintain comfort.

Insulated boots include a layer of material designed to trap air and retain heat, keeping your feet warm in extreme cold.

Ankle Support and Stability

Work boots are almost always high-cut for a reason.

This design provides crucial ankle support, helping to prevent twists and sprains on uneven terrain. The taller boot also protects the ankle area from abrasions and impacts.

Understanding the Trade-offs

Choosing a work boot involves balancing protection with practical considerations. More features are not always better.

Protection vs. Comfort

Added safety features often come with compromises. Steel midsoles and metatarsal guards add significant weight and can reduce flexibility.

Likewise, heavy insulation that is perfect for winter becomes a liability in the summer, and a waterproof membrane can reduce a boot's breathability.

The Importance of Certification

A feature is only reliable if it meets established safety standards. Legitimate safety footwear must be certified to pass tests for impact resistance, compression, and slip resistance.

An uncertified boot offers no guarantee of protection. Always look for the official PPE standard rating (such as ASTM F2413 in the U.S.) on the boot's tag.

Matching the Boot to Your Job

Use your primary work environment as your guide to select the essential features you need.

- If your primary focus is electrical work: Prioritize boots with a clear Electrical Hazard (EH) rating to protect against shock.

- If your primary focus is construction or demolition: Look for penetration-resistant midsoles and metatarsal guards for maximum impact and puncture protection.

- If your primary focus is working outdoors or in wet conditions: Insist on a fully waterproof boot to keep your feet dry and comfortable.

- If your primary focus is on slick surfaces like kitchens or auto shops: A certified slip and oil-resistant outsole is the most critical feature for preventing falls.

Ultimately, selecting the right work boot is an essential investment in your personal safety and daily well-being.

Summary Table:

| Feature | Primary Benefit | Ideal For |

|---|---|---|

| Electrical Hazard (EH) Rating | Reduces risk of electric shock | Electricians, utility workers |

| Puncture-Resistant Midsole | Protects against sharp objects | Construction, demolition |

| Metatarsal Guard | Shields top of foot from impacts | Heavy industry, manufacturing |

| Slip-Resistant Outsole | Improves traction on slick surfaces | Kitchens, auto shops, warehouses |

| Waterproof Membrane | Keeps feet dry in wet conditions | Outdoor work, plumbing, agriculture |

| Thermal Insulation | Retains heat in cold environments | Cold storage, winter construction |

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots and safety shoes, ensuring you get the right protection for your specific job hazards. Contact us today to discuss your work boot requirements and discover how our expertise can enhance your safety program!

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- What is the purpose of electric hazard boots? Essential Protection for Electrical Workers

- What are the main types of materials used for work boot uppers? A Guide to Leather, Synthetics & Rubber

- What are structural fire boots designed for? Essential Protection for Interior Firefighting

- How does flexibility compare among PVC, neoprene, and rubber work boots? Find Your Perfect Fit for All-Day Comfort

- What is the average lifespan of work boots? Extend Your Boots' Life with Expert Care

- How should farm boots be cleaned? A Complete Guide to Preserve Your Investment

- What are the functional purposes of the cowboy boot's design? Uncover the Engineering Behind the Icon

- What are the main types of safety toe boots? Choose the Right Protection for Your Job