The two critical standards for work boots are the guidelines set by the Occupational Safety and Health Administration (OSHA) and the performance specifications defined by ASTM International (formerly the American Society for Testing and Materials). OSHA determines when protective footwear is necessary based on a workplace hazard assessment, while the ASTM F2413 standard details the specific performance ratings a boot must meet to be considered safe.

The most effective way to select work boots is to match the specific hazard ratings on the boot's ASTM label directly to the known risks of your job. It's not about finding the "safest" boot in general, but the right boot for your specific environment.

The Two Pillars of Work Boot Safety

Understanding the roles of OSHA and ASTM is the first step. One entity sets the requirement, and the other defines the standard of protection.

OSHA: The "Why" and "When"

OSHA is the governing body that mandates employers provide a safe working environment. This includes requiring protective footwear wherever there is a danger of foot injuries.

OSHA does not certify specific boots. Instead, it requires that employers assess their workplace for hazards and ensure employees wear footwear that meets an appropriate performance standard, like ASTM F2413.

ASTM F2413: The "What" and "How"

This is the primary technical standard for protective footwear in the United States. A boot that is compliant with ASTM F2413 has been lab-tested for resistance against specific, measurable hazards.

You can find these ratings on a label sewn inside the boot. Understanding this label is the key to making an informed choice.

Decoding the ASTM F2413 Label

The ASTM label uses a simple coding system to tell you exactly what the boot protects against. The most common ratings are for impact and compression resistance.

Impact (I) and Compression (C) Protection

This is the most fundamental safety feature, referring to the protective toe cap. The standard is typically marked as I/75 and C/75.

I/75 means the toe cap can withstand an impact of 75 foot-pounds, equivalent to a 50-pound weight being dropped from about 1.5 feet.

C/75 means the toe cap can withstand a compressive load of 2,500 pounds before cracking or breaking.

Toe caps can be made from steel, composite materials, or even nano-carbon fiber, all of which can achieve the same I/75 C/75 rating.

Metatarsal (Mt) Protection

This rating indicates the boot has an integrated guard that protects the top of your foot (the metatarsal bones) from impact. It is crucial for roles where objects could drop or roll onto the foot.

Electrical Hazard (EH) Protection

EH-rated boots are designed with non-conductive, shock-resistant soles and heels. They are built to provide a secondary source of protection against accidental contact with live electrical circuits.

Static Dissipative (SD) Protection

Unlike EH boots, SD footwear is designed to reduce the buildup of static electricity. This is critical in environments with sensitive electronics or flammable materials where a static discharge could be hazardous.

Puncture Resistance (PR)

Boots with a PR rating have a puncture-resistant plate built into the midsole. This plate protects your foot from sharp objects you might step on, such as nails or scrap metal.

Understanding the Trade-offs

No single boot is perfect for every situation. Choosing the right one means balancing protection with practical needs.

Steel vs. Composite Toe Caps

Steel toes offer maximum protection and have been the industry standard for decades. However, they are heavier and conduct temperature.

Composite toes are lighter, do not conduct heat or cold, and will not set off metal detectors. They are ideal for workers who need protection without the added weight or conductivity of steel.

Specialized Features vs. General Use

A boot packed with every feature isn't always better. For instance, the construction required for an EH rating can be undermined by adding a PR plate, and SD boots serve a purpose directly opposite to that of EH boots.

Focus on the specific protections your job requires rather than simply seeking the most features.

Comfort and Fit are Non-Negotiable

A perfectly rated boot is useless if it's too uncomfortable to wear correctly or consistently. An improper fit can cause blisters, fatigue, and even lead to slips or falls. Safety and comfort are not mutually exclusive; they are co-dependent.

How to Select the Right Boot

Start with your employer's or worksite's safety assessment. If you are choosing on your own, analyze the most common risks you face daily.

- If your primary focus is protection from falling objects: Ensure the boot is rated I/75 and C/75.

- If you work around live electrical circuits: An EH-rated boot is non-negotiable for your safety.

- If you work with sensitive electronics or in flammable environments: You need Static Dissipative (SD) footwear to prevent static discharge.

- If you face puncture hazards from below (e.g., construction sites): A Puncture Resistant (PR) rating is essential.

- If you work on varied or slippery surfaces: Pay close attention to the outsole material (e.g., rubber for oil resistance) and tread design (e.g., deep lugs for mud).

Ultimately, choosing the right work boot is a critical decision that directly impacts your daily safety and well-being.

Summary Table:

| Key ASTM F2413 Safety Rating | What It Protects Against |

|---|---|

| I/75 & C/75 | Impact and compression from falling objects (e.g., steel toe). |

| Mt | Impact to the top of the foot (metatarsal bones). |

| EH | Accidental contact with live electrical circuits. |

| SD | Buildup of static electricity in sensitive environments. |

| PR | Puncture hazards from sharp objects like nails. |

Protect your workforce with the right safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-compliant work boots for distributors, brand owners, and bulk clients. Whether you need steel toe, composite, EH-rated, or puncture-resistant boots, our production capabilities ensure quality, durability, and the precise safety ratings your customers require. Contact us today to discuss your footwear needs and get a quote.

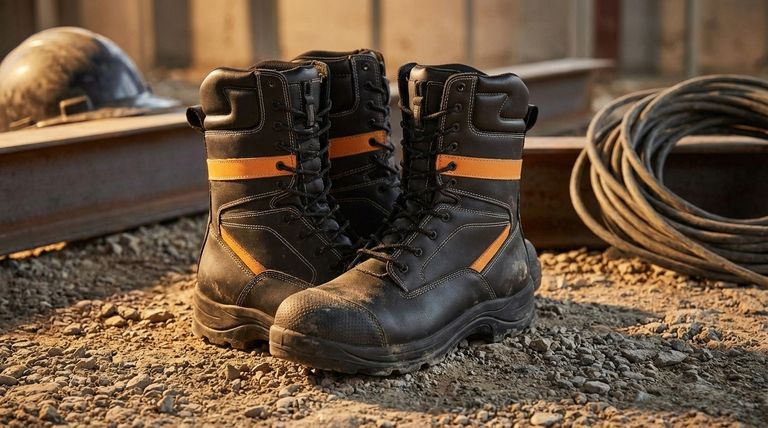

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- What organization sets the standards for wildland fire boots? The NFPA 1977 Guide

- What are the requirements for compression resistance in safety toe boots? Ensure OSHA & ASTM F2413 Compliance

- How does the design of wildland firefighter boots support comfort and functionality? Engineered for Stability and Endurance

- What industries benefit most from soft-toe boots? Prioritize Comfort and Agility for Your Workforce

- What are the purpose-specific features of western boots and work boots? Choose the Right Footwear for Your Job

- Why is it recommended to try on work boots before buying them? Ensure Perfect Fit & Safety

- How do oilfield boots ensure comfort during long shifts? The Ultimate Guide to All-Day Support

- Why are waterproof work boots important and who should use them? Essential Foot Protection for Outdoor & Wet Work