Checking the labels on steel cap work boots is the only reliable method to verify their protective capabilities. A boot's label is not a feature list; it is a technical specification that confirms it meets mandatory safety standards and details the specific hazards it is designed to mitigate. Without this label, you are simply guessing about your own safety.

A work boot's label is a standardized code that decodes its specific safety certifications and protective features. Understanding this code ensures you are purchasing genuine, tested protection, not just the appearance of safety.

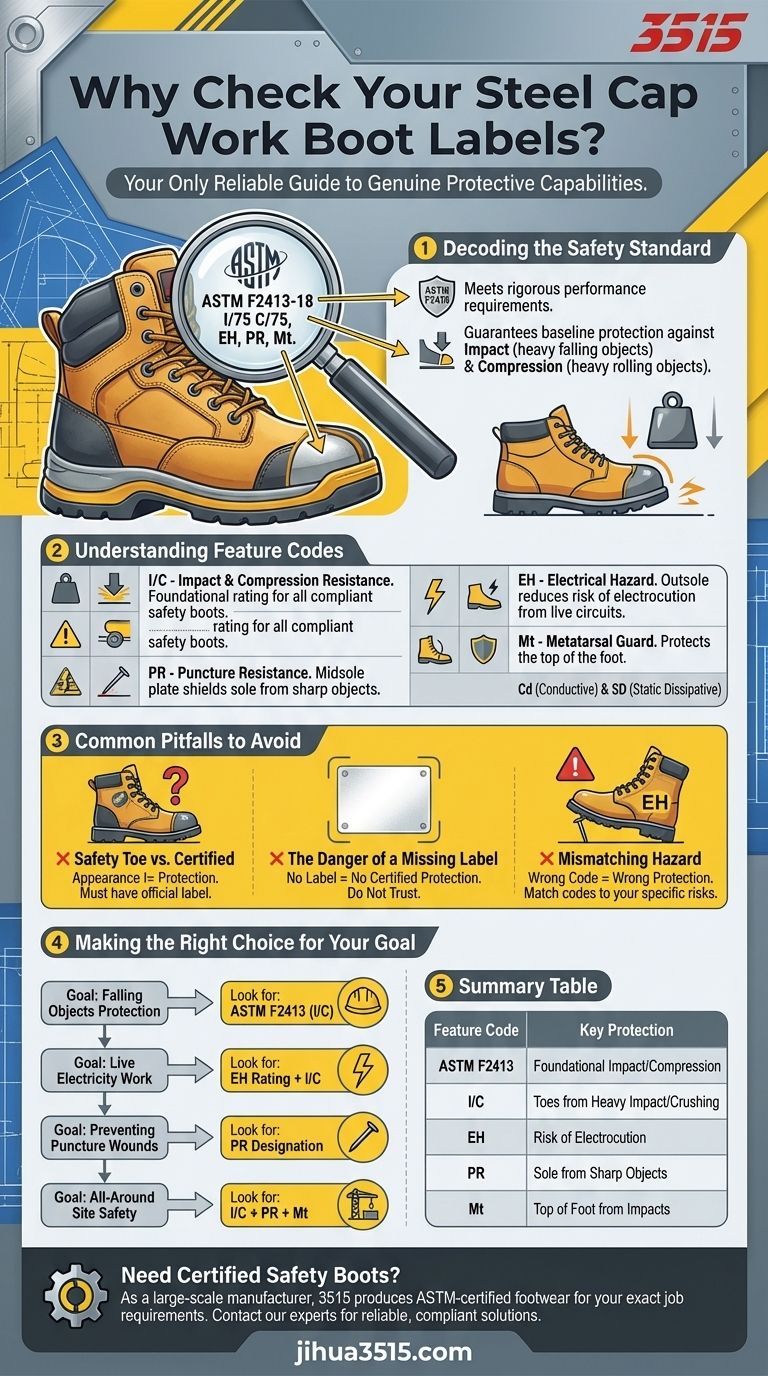

Decoding the Safety Standard

The primary function of a safety boot label is to prove that it meets a specific, recognized safety standard. This is the foundation upon which all other features are built.

What the Standard Guarantees

A safety standard, such as ASTM F2413 in the United States, is a set of rigorous performance requirements. A boot that carries this designation has been independently tested to withstand specific levels of impact and compression.

The Importance of Certification

This certification proves the protective toe cap can protect your feet from a heavy falling object (impact) and from being crushed under a heavy rolling object (compression). It is a guarantee of baseline performance.

How to Find the Standard

The label is typically sewn inside the boot's tongue or upper. It will clearly list the standard it conforms to, often with the year of the standard it was tested against (e.g., ASTM F2413-18).

Understanding the Feature Codes

Beyond the basic standard, the label uses a series of simple codes to indicate additional protective features. This allows you to match a boot's capabilities to your specific work environment.

Impact and Compression (I/C)

These are the foundational ratings for the safety toe itself. The "I" stands for impact resistance, and the "C" stands for compression resistance. All compliant safety boots will have these designations.

Electrical Hazard (EH)

An EH rating means the outsole is designed to significantly reduce the potential for electrocution when stepping on live electrical circuits. This is critical for electricians and maintenance workers.

Puncture Resistance (PR)

Boots with a PR rating have a puncture-resistant plate built into the midsole. This protects the sole of your foot from sharp objects like nails, a common hazard on construction sites.

Other Common Codes

You may also see codes like Mt for metatarsal guards (protecting the top of the foot), Cd for conductive properties (to reduce static electricity buildup), or SD for static dissipative.

Common Pitfalls to Avoid

Relying on a boot's appearance or marketing claims instead of its official label can lead to serious injury. The label is your only source of truth.

"Safety Toe" vs. Certified Protection

A boot can have a hard toe and be marketed as a "safety boot" without ever passing the required tests. If it lacks a label with a recognized standard like ASTM F2413, it offers no guaranteed protection.

The Danger of a Missing Label

Never purchase a work boot for a hazardous environment if it does not have a safety specification label. Its absence means it has not been certified and should not be trusted for workplace safety.

Mismatching the Boot to the Hazard

Buying a certified boot is only half the battle. You must ensure its specific feature codes match your job's risks. An expensive EH-rated boot provides no protection from a nail on the ground if it is not also PR-rated.

Making the Right Choice for Your Goal

Use the boot's label to match its certified features directly to the hazards you face every day.

- If your primary focus is protection from falling objects: Ensure the label lists a recognized impact (I) and compression (C) standard, such as ASTM F2413.

- If your primary focus is working around live electricity: Look for the Electrical Hazard (EH) rating in addition to the standard impact and compression codes.

- If your primary focus is preventing sole punctures from nails: Verify the boot has a Puncture Resistant (PR) designation on its label.

- If your primary focus is all-around construction site safety: Seek a boot that combines I/C ratings with both PR and potentially Mt (Metatarsal) protection.

Ultimately, the label on your work boot is your most reliable safety partner, translating complex engineering into a clear promise of protection.

Summary Table:

| Feature Code | What It Means | Key Protection |

|---|---|---|

| ASTM F2413 | Meets US Safety Standard | Foundational Impact/Compression Rating |

| I/C | Impact & Compression Resistance | Protects toes from heavy falling/crushing objects |

| EH | Electrical Hazard Resistance | Reduces risk of electrocution from live circuits |

| PR | Puncture Resistance | Shields sole from sharp objects like nails |

| Mt | Metatarsal Guard | Protects the top of the foot from impacts |

Need certified safety boots that meet your exact job requirements?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring genuine protection tailored to your hazards.

Contact our experts today for reliable, compliant footwear solutions.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How can one avoid foot problems when wearing steel toe boots? Essential Tips for Daily Comfort & Health

- What are the characteristics of a properly fitting steel toe boot? Achieve All-Day Safety and Comfort

- How should you properly break in new steel toe boots? A 3-Phase Guide for Lasting Comfort

- What are the key differences in conductivity between steel and composite toe caps? Choose the Safer, More Comfortable Option

- What safety standards do modern steel toe boots adhere to? Understanding ASTM & EN ISO for Maximum Protection

- Why do landscapers need steel-toe boots? Essential Protection for a Hazardous Job

- What are the primary safety functions of safety boots with steel-toe designs? Essential Protection for Industry

- What are the key benefits of steel toe boots? Unmatched Protection & Durability