To properly break in new steel toe boots, you must follow a gradual, phased approach. Begin by wearing them indoors for only a few hours at a time with your standard work socks. As the initial stiffness subsides, progress to short walks, and finally, wear them to your job for partial days, always keeping a comfortable backup pair of boots on hand. This methodical process allows the boot's materials to slowly conform to your foot's shape, preventing the blisters and pain that come from rushing it.

The core principle is this: You are not breaking in the steel toe—it is inflexible. You are methodically molding the leather and other materials around the protective cap to fit the unique contours of your foot. A successful break-in is impossible without a correct initial fit.

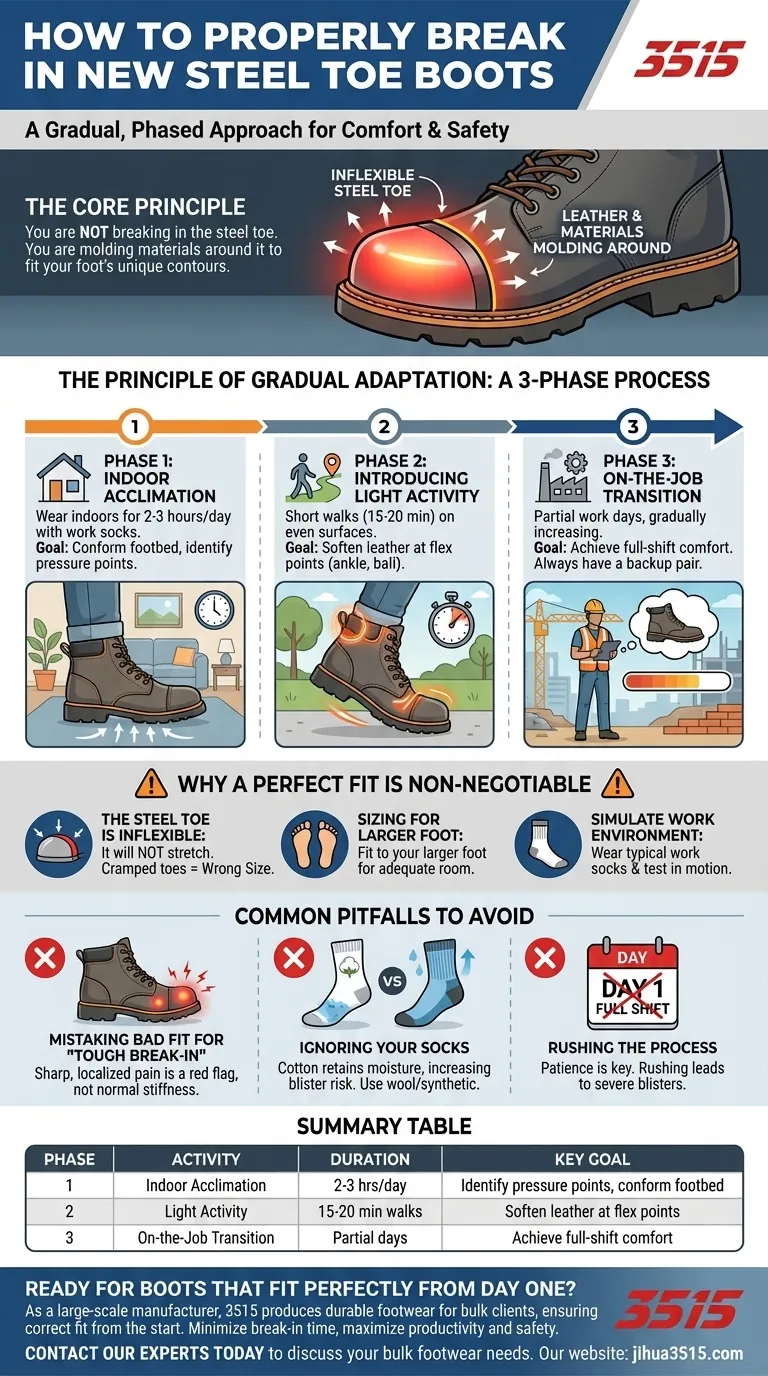

The Principle of Gradual Adaptation

The discomfort from new boots comes from rigid materials creating friction and pressure points against your foot. The goal is to make these materials pliable and form-fitting without causing tissue damage like blisters. This requires a deliberate, multi-stage process.

Phase 1: Indoor Acclimation

Start by wearing the new boots around your house for 2-3 hours per day. Always wear the same type of thick, moisture-wicking socks you use for work.

This initial phase helps the boot's footbed begin to compress and conform to your sole. It also allows you to identify any immediate, painful pressure points before you commit to wearing them outside or on the job.

Phase 2: Introducing Light Activity

Once the boots feel reasonably comfortable for indoor wear, begin taking them on short walks. A 15-20 minute walk on a sidewalk or other even surface is ideal.

This step introduces flexion at the ankle and ball of the foot. The repeated bending and movement begins to soften the leather and synthetics in these critical areas, which is essential for long-term comfort.

Phase 3: The On-the-Job Transition

After a few days of light activity, you can start wearing the boots to work. However, do not attempt to wear them for a full shift initially.

Bring your old, trusted pair of boots with you. Wear the new boots for the first half of the day and switch into your old ones if you feel any significant discomfort developing. Gradually increase the wear time over several days until you can comfortably last a full shift.

Why a Perfect Fit is Non-Negotiable

No break-in procedure can fix a boot that is fundamentally the wrong size or shape for your foot. The process only works when you start with the correct foundation.

The Steel Toe is Inflexible

This is the most critical concept to understand. The protective toe cap, whether steel, composite, or alloy, will not stretch or change shape.

If you feel your toes are cramped or rubbing against the safety cap, the boot is too small, too narrow, or the wrong shape. This is a fit issue that will never improve with time.

Sizing for Your Larger Foot

Most people have one foot that is slightly larger than the other. Always fit your boots to your larger foot to ensure you have adequate room and prevent cramping.

Simulating Your Work Environment

When trying on boots, always wear your typical work socks. A thin dress sock can give you a false sense of a good fit.

Walk around the store for several minutes to see how the boot feels in motion. Check for heel slippage and ensure the ball of your foot aligns with the boot's natural flex point.

Common Pitfalls to Avoid

Achieving a comfortable fit requires avoiding common mistakes that can derail the process and cause unnecessary pain.

Mistaking a Bad Fit for a "Tough Break-in"

General stiffness throughout the boot is normal and will subside. However, sharp, localized pain—especially around the toe cap or heel—is a major red flag for a poor fit. Do not try to "tough it out."

Ignoring Your Socks

Cotton socks retain moisture, which softens the skin and dramatically increases the risk of blisters from friction. Always opt for high-quality wool or synthetic work socks that wick moisture away from your skin.

Rushing the Process

Patience is the most important tool in breaking in new boots. Attempting to wear a brand-new, stiff pair of leather boots for a full 10-hour shift is the primary cause of severe blisters and foot pain.

Making the Right Choice for Your Goal

Your approach should be guided by your primary need, whether it's immediate wearability or long-term performance.

- If your primary focus is maximum durability: Stiff, full-grain leather boots often require the longest break-in period but will eventually provide a superior, custom fit that lasts.

- If your primary focus is out-of-the-box comfort: Look for boots made with more flexible materials or those that feature comfort technology like padded collars and tongues, but understand a gradual break-in is still essential.

- If you feel any pressure from the steel toe cap: Stop. This is a critical fit problem, not a break-in issue. You must return the boots and find a model with a wider or differently shaped toe box.

Ultimately, treating your boots as a critical piece of equipment that requires proper conditioning is the key to achieving safety and comfort that work together.

Summary Table:

| Phase | Activity | Duration | Key Goal |

|---|---|---|---|

| 1: Indoor Acclimation | Wear indoors | 2-3 hours/day | Identify pressure points, conform footbed |

| 2: Light Activity | Short walks | 15-20 minutes | Soften leather at flex points (ankle, ball) |

| 3: On-the-Job Transition | Partial work days | Gradually increase | Achieve full-shift comfort without pain |

Ready for Boots That Fit Perfectly From Day One?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and work shoes, designed with both comfort and long-term performance in mind.

Let us help you equip your team with the right footwear. We ensure a correct fit from the start, minimizing break-in time and maximizing productivity and safety.

Contact our experts today to discuss your bulk footwear needs and find the perfect solution for your workforce.

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

- Durable Steel Toe Safety Boots Wholesale & Custom Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- When should you seek professional help for foot pain caused by steel toe boots? Recognize the Warning Signs

- How much weight can steel toe boots typically withstand? 2,500 lbs of Crush Protection Explained

- What are the advantages of wearing steel toe shoes? Maximum Protection for Your Workforce

- What is the importance of choosing the right size for steel toe boots? Avoid Injury and Boost Productivity

- What industries are steel toe boots commonly used in? Essential Foot Protection for High-Risk Work

- What factors should be considered when choosing between composite toe and steel toe shoes? Select the Right Safety Footwear for Your Job

- Which industries commonly use steel toe boots? Essential Foot Protection for High-Risk Jobs

- What are the key differences between steel toe and composite toe caps? Choose the Right Safety for Your Job