Modern steel toe boots are governed by globally recognized safety standards designed to ensure they provide verified, life-saving protection. The primary standards in the United States are set by the American Society for Testing and Materials (ASTM), while the EN ISO standards are the benchmark in Europe and internationally. These frameworks are enforced by regulatory bodies like OSHA to guarantee footwear can withstand specific, measurable workplace hazards.

The core purpose of safety standards is to move beyond marketing claims and provide a verifiable guarantee. An ASTM or EN ISO rating means a boot has been lab-tested to protect against specific threats like heavy impacts and crushing forces, ensuring it performs when you need it most.

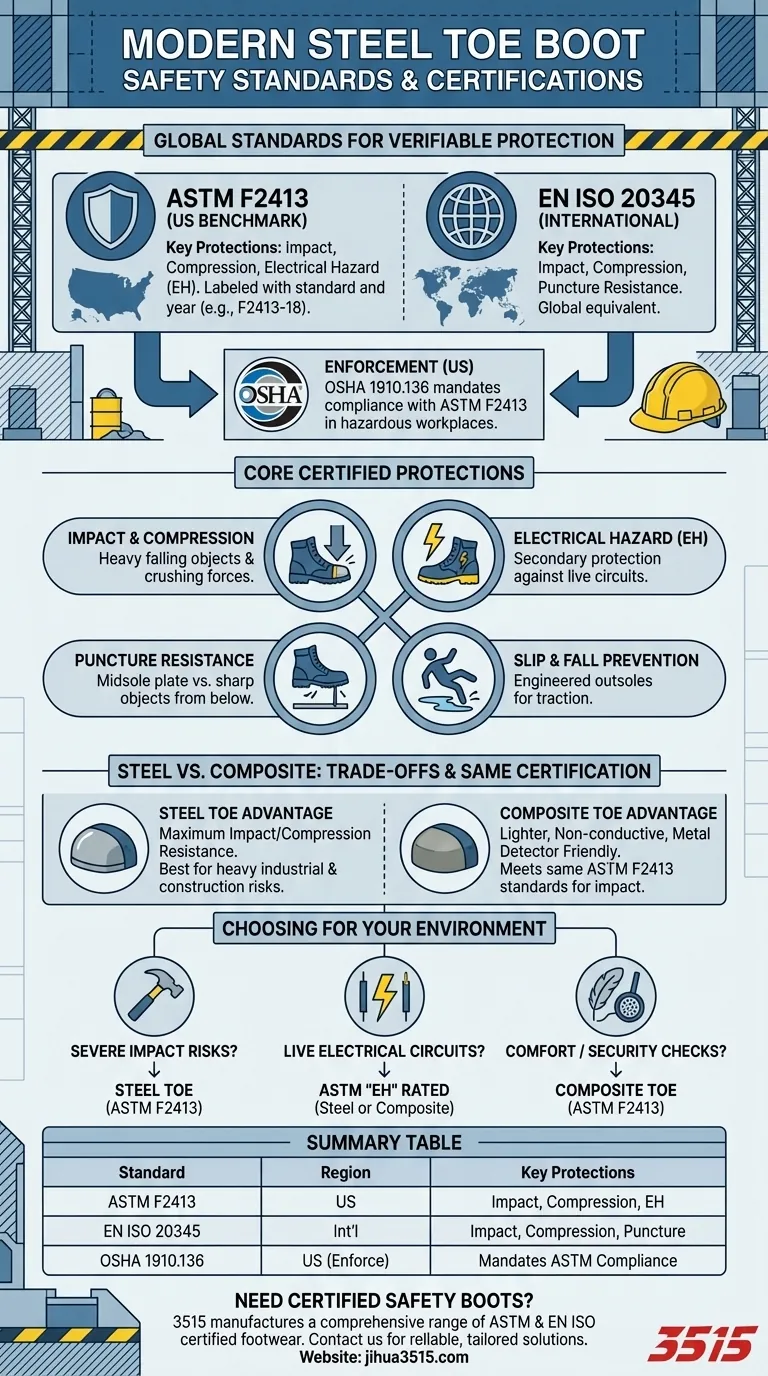

Decoding the Key Standards

To select the right footwear, it's essential to understand what the labels on the boot's tongue actually mean. These codes represent specific, tested capabilities.

ASTM F2413: The US Benchmark

The most common standard you will see in the United States is ASTM F2413. This is the standard specification for performance requirements for protective (safety) toe cap footwear.

This standard verifies a boot's resistance to several key hazards. Any boot meeting this standard will be clearly labeled, often followed by the year of the last update (e.g., ASTM F2413-18).

EN ISO 20345: The International Standard

For footwear manufactured or sold internationally, you will frequently encounter the EN ISO 20345 standard. This is the European and international equivalent to the ASTM standard.

While the testing methods may differ slightly, its goal is the same: to certify that the footwear provides adequate protection against common industrial hazards, particularly impact and compression.

OSHA's Role: The Enforcement Framework

The Occupational Safety and Health Administration (OSHA) provides the legal requirement for protective footwear in the US under Standard 1910.136.

OSHA does not create its own footwear standards. Instead, it mandates that employers ensure employees use protective footwear that complies with consensus standards like ASTM F2413 in any workplace where there is a danger of foot injury.

What Protections Do These Standards Guarantee?

A certification is meaningless without understanding the real-world protection it represents. These standards test for specific, critical safety functions.

Impact and Compression Resistance

This is the fundamental purpose of a steel toe boot. The footwear is tested for its ability to protect the wearer's toes from a heavy falling object (impact) and from being crushed under a heavy rolling object (compression).

Electrical Hazard (EH) Protection

Many certified boots carry an "EH" rating. This indicates the outsole can provide a secondary source of protection against accidental contact with live electrical circuits, helping to reduce the potential for electric shock.

Puncture Resistance

Some boots are also designed with a steel or composite plate in the midsole to protect the foot from being punctured by sharp objects from below, like nails or scrap metal.

Slip and Fall Prevention

While not part of the toe cap standard itself, the overall design of safety footwear includes outsoles engineered to prevent slips, trips, and falls, which are among the most common workplace accidents.

Understanding the Trade-offs: Steel vs. Composite

Both traditional steel toe and modern composite toe boots can be certified to the exact same ASTM standards. The difference lies in their material properties and the secondary benefits they offer.

The Steel Toe Advantage: Maximum Protection

Steel offers the highest level of resistance to impact and compression. It has been the trusted standard for decades in heavy industrial, construction, and manufacturing environments where the risk of falling objects is severe.

The Composite Toe Advantage: Modern Versatility

Composite toes are made from non-metal materials like Kevlar, carbon fiber, or plastic. They are lighter than steel, do not conduct heat or cold, and will not set off metal detectors.

Critically, a composite toe boot that is ASTM F2413 certified provides the same level of tested impact and compression protection as its steel counterpart.

Making the Right Choice for Your Environment

Your choice should be dictated by the specific hazards of your job, not just the material of the toe cap.

- If your primary focus is heavy industry with severe impact risks: A steel toe boot rated to the latest ASTM F2413 standard offers the most proven defense.

- If your primary focus is working around live electrical circuits: You must select a boot with a specific ASTM "EH" rating, regardless of whether the toe is steel or composite.

- If your primary focus is comfort, temperature insulation, or passing through metal detectors: A composite toe boot certified to ASTM F2413 provides the necessary impact protection without the drawbacks of metal.

Understanding these standards allows you to move beyond the material and choose footwear based on certified, tested protection for your specific job.

Summary Table:

| Standard | Region | Key Protections |

|---|---|---|

| ASTM F2413 | United States | Impact, Compression, Electrical Hazard (EH) |

| EN ISO 20345 | Europe & International | Impact, Compression, Puncture Resistance |

| OSHA 1910.136 | United States (Enforcement) | Mandates use of ASTM-compliant footwear |

Need certified safety boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM and EN ISO certified footwear for distributors, brand owners, and bulk clients. We ensure every pair meets the highest safety standards for impact, compression, and electrical hazards.

Contact us today for reliable, certified protective footwear tailored to your industry's needs.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- What is the overall recommendation regarding steel toe boot usage? Essential for Maximum Protection

- How do women's safety toe work boots protect against foot injuries? A Complete Guide to Workplace Foot Safety

- What safety features can some gumboots have? Essential PPE for Hazardous Work Environments

- What are steel toe boots and how are they designed? Essential Guide to Industrial Footwear Safety

- In what work situations might cowboy boots not be appropriate? A Guide to Safety & Dress Code Compliance