Ultimately, any worker exposed to cold conditions needs insulated work boots, a category that commonly includes construction laborers, farmhands, utility workers, and individuals working in refrigerated environments like warehouses or food processing plants. The primary function of these boots is to prevent dangerous heat loss and protect feet from cold-related injuries.

The decision to use insulated boots isn't about a specific job title, but about the environment. It's a calculated choice based on temperature, moisture, and your personal activity level to maintain safety and comfort.

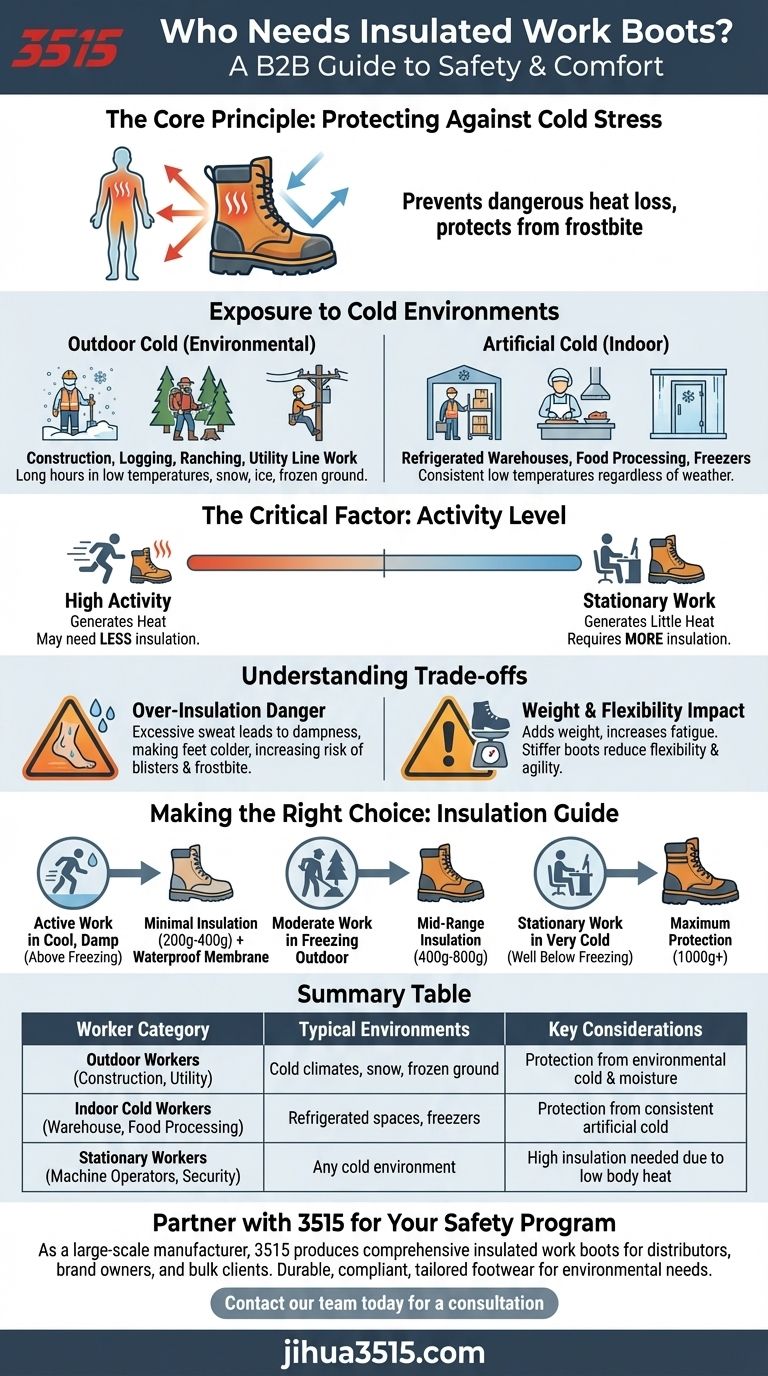

The Core Principle: Protecting Against Cold Stress

Insulated footwear is a critical piece of personal protective equipment (PPE) designed to slow the transfer of heat from your body to the cold environment. Without it, workers face risks ranging from severe discomfort to serious medical conditions like frostbite.

Exposure to Environmental Cold

Workers who spend significant time outdoors in fall, winter, or in colder climates are the most obvious candidates. This includes a wide range of professions.

Professions like construction, logging, ranching, and utility line work often involve long hours in low temperatures, snow, and ice. Standing on frozen ground rapidly leaches heat from the feet.

Exposure to Artificial Cold

Cold isn't just an outdoor problem. Many modern occupations require working in artificially cold spaces for entire shifts.

This applies directly to those in refrigerated warehouses, food processing facilities, and walk-in freezers. In these roles, the temperature is consistently low regardless of the weather outside.

The Critical Factor of Activity Level

Your level of physical exertion plays a massive role in determining your insulation needs. The more you move, the more body heat you generate.

A worker who is highly active, such as a laborer constantly moving materials, generates significant metabolic heat and may need less insulation. In contrast, a stationary worker, like a machine operator or a security guard, generates very little heat and requires much more insulation to stay warm.

Understanding the Trade-offs

Choosing the right insulation is a balance. More is not always better, and selecting the wrong boot can create new problems.

The Danger of Over-Insulation

Wearing boots that are too warm for your activity level or environment is a common mistake. It leads to excessive sweating.

Trapped moisture from sweat will dampen your socks and skin. This moisture eliminates the insulating properties of your socks and can ironically make your feet feel even colder, increasing the risk of blisters and frostbite.

The Impact of Weight and Flexibility

Insulation adds material, which adds weight and bulk to the boot. Heavier boots can increase fatigue over a long workday.

Heavily insulated boots are also often stiffer, which can reduce flexibility and comfort for jobs that require agility or climbing.

Making the Right Choice for Your Environment

Your boot choice should be a direct response to your specific working conditions.

- If your primary focus is active work in cool, damp conditions (above freezing): A boot with minimal insulation (200g-400g) combined with a waterproof membrane is often ideal.

- If your primary focus is moderate work in freezing outdoor temperatures: A mid-range insulation level (400g-800g) provides a solid balance of warmth without excessive bulk.

- If your primary focus is stationary work in very cold conditions (well below freezing): You need maximum protection from a heavily insulated boot (1000g or more) to compensate for your lack of generated body heat.

Ultimately, matching your footwear to the specific thermal hazards of your job is a fundamental requirement for workplace safety.

Summary Table:

| Worker Category | Typical Environments | Key Considerations |

|---|---|---|

| Outdoor Workers (Construction, Utility, Logging) | Cold climates, snow, frozen ground | Protection from environmental cold and moisture. |

| Indoor Cold Workers (Warehouse, Food Processing) | Refrigerated spaces, freezers | Protection from consistent artificial cold. |

| Stationary Workers (Machine Operators, Security) | Any cold environment | High insulation needed due to low body heat generation. |

Ensure your team's safety and comfort in the cold with the right insulated boots. As a large-scale manufacturer, 3515 produces a comprehensive range of insulated work boots for distributors, brand owners, and bulk clients. Our expertise ensures durable, compliant footwear tailored to your specific environmental needs. Contact our team today for a consultation and discover how we can support your safety program.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What are the characteristics of lineman boots? Essential Safety & Support for Utility Workers

- What weather and chemical protections do premium boots offer? Your Complete Guide to Safety & Performance

- What are the 11 NFPA 1977 standards for wildland fire boots? Ensure Total Foot Protection on the Fire Line

- What are the key components of modern work boots? Engineered for Ultimate Durability and Comfort

- What types of toe protection are available in work-safe boots? Choose the Right Safety Toe for Your Job

- How should work boots be maintained to prolong their lifespan? Essential Care for Long-Lasting Safety

- How do composite toe work boots affect work productivity? Reduce Fatigue & Boost Performance

- What should potential buyers consider when purchasing lace-to-toe boots? A Guide to Fit & Function