The short answer is yes. Composite toe work boots positively affect productivity primarily by reducing worker fatigue. Their lighter weight and enhanced comfort compared to traditional steel toe boots allow professionals to conserve energy and maintain focus throughout long, physically demanding shifts.

The key to understanding productivity isn't just about the safety rating of the boot, but about the total physical cost of wearing it for 8 to 12 hours. By minimizing weight without compromising on essential protection, composite toe boots reduce this physical cost, directly contributing to sustained performance.

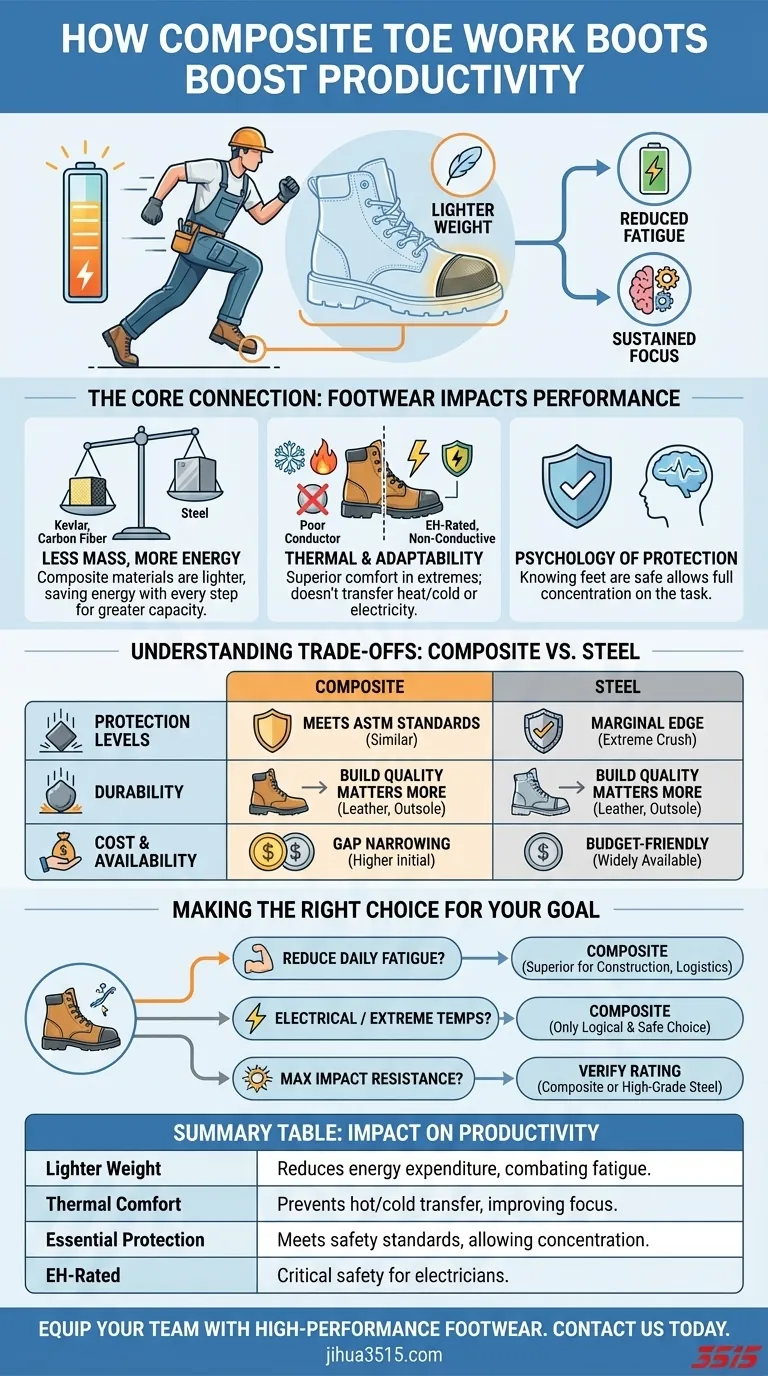

The Core Connection: How Footwear Impacts Performance

A worker's footwear is a foundational piece of equipment. If it's heavy, ill-fitting, or unsuitable for the environment, it creates a constant, low-level drain on physical and mental energy that compounds over a workday.

The Weight Factor: Less Mass, More Energy

Composite toe caps are made from non-metal materials like Kevlar, carbon fiber, or high-tech plastics.

These materials provide the necessary structural integrity to meet safety standards but are significantly lighter than steel.

This weight reduction means less energy is expended with every step. Over thousands of steps in a single shift, this saved energy translates directly into reduced fatigue and a greater capacity to focus on the task at hand.

Thermal Comfort and Environmental Adaptability

Unlike steel, composite materials are poor conductors of heat and electricity.

This makes them superior in extreme temperatures. They don't transfer cold to the foot in winter or heat in the summer, which improves overall comfort and reduces a major environmental distraction.

For electricians or those working in sensitive environments, the non-conductive (EH-rated) and metal-free properties are a critical safety feature that allows them to work with greater confidence.

The Psychology of Protection

Productivity is also a function of focus. Knowing your feet are protected from crush, cut, and puncture hazards allows you to concentrate fully on your work.

Composite boots provide this high level of protection, meeting the same safety standards as steel toes for most common workplace hazards found in construction, forestry, and manufacturing.

Understanding the Trade-offs: Composite vs. Steel

While composite boots offer clear productivity benefits, they are not universally superior to steel in every single metric. An objective choice requires understanding the specific trade-offs.

Protection Levels at the Extremes

For most applications, composite and steel toe boots that meet the same ASTM safety standard offer comparable impact and compression protection.

However, in scenarios involving exceptionally heavy or sharp objects, some high-grade steel toes may offer a marginal advantage in ultimate crush resistance. The key is to match the boot's specific rating to your worksite's known hazards.

Durability and Material Construction

The durability of the boot is less about the toe material and more about the overall build quality.

Look for features like full-grain leather, abrasion-resistant outsoles with deep lugs for traction, and thermoplastic polyurethane (TPU) toe protectors. These elements contribute more to the boot's lifespan than the choice between composite and steel.

Cost and Availability

Historically, composite toe boots carried a higher price tag. While this gap has narrowed significantly, steel toe options often remain more budget-friendly and are widely available in a vast range of styles.

Making the Right Choice for Your Goal

Selecting the correct boot is a strategic decision. Base your choice on the primary demands of your specific role and environment.

- If your primary focus is reducing daily fatigue: Composite toe boots are the superior choice for most workers in construction, logistics, and manufacturing due to their significant weight savings.

- If your primary focus is working with electrical hazards or in extreme temperatures: Composite is the only logical and safe choice due to its non-conductive, non-thermal properties.

- If your primary focus is maximum impact resistance in the heaviest industrial settings: Verify that the specific safety rating of a composite boot meets your needs, but don't rule out a high-quality steel toe if it provides a higher certified level of protection.

Choosing the right work boot is a direct investment in your daily performance and long-term well-being.

Summary Table:

| Feature | Impact on Productivity |

|---|---|

| Lighter Weight | Reduces energy expenditure, combating fatigue over long shifts. |

| Thermal Comfort | Non-conductive materials prevent hot/cold transfer, improving focus. |

| Essential Protection | Meets safety standards, allowing workers to concentrate on tasks. |

| EH-Rated (Non-Conductive) | Critical safety for electricians, enabling confident work. |

Ready to equip your team with high-performance footwear that boosts productivity?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of composite toe and steel toe boots designed to enhance worker comfort, safety, and efficiency.

Contact us today to discuss your specific needs and discover how our durable, comfortable work boots can be a strategic investment in your team's performance.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What are the best practices for storing leather work boots? Preserve Your Investment for Years

- What are toe caps in work boots and why are they important? Choose the Right Protection for Your Job

- Why are customized 3D printed measurement boots utilized in a sled friction meter? Elevate Testing Accuracy

- What types of electrical hazard protection are available in work boots? EH vs. SD Safety Explained

- What standard should work boots meet for safety in Australia? Ensure AS 2210.3:2019 Compliance

- What environmental conditions damage firefighter boots? The Hidden Cycle of Heat, Water & Chemicals

- What are the disadvantages of synthetic/leather boots? The Long-Term Value Trade-Off

- What makes Western-style work boots comfortable? Unlock All-Day Comfort with Advanced Design