At their core, lineman boots are a highly specialized system designed for the unique and hazardous work of climbing utility poles and transmission towers. They are defined by a combination of critical features: a tall shaft for ankle support, a heavy-duty steel shank for standing on pegs or gaffs, a raised heel to lock into climbing gear, and an Electrical Hazard (EH) rating for safety.

The specific characteristics of a lineman boot are not arbitrary; they form an integrated system where each component is engineered to provide the support, protection, and stability required to work safely and effectively at extreme heights.

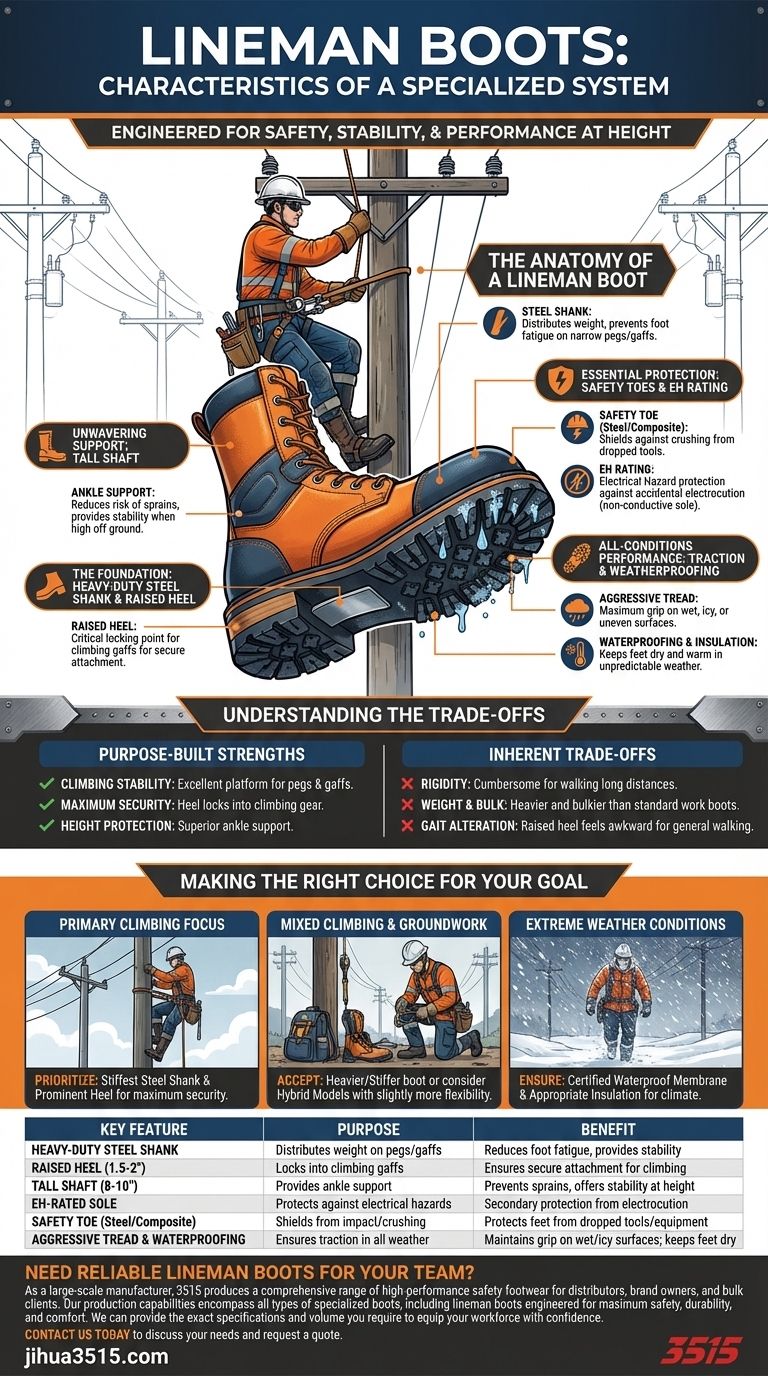

The Anatomy of a Lineman Boot: A System for Safety

A lineman boot is purpose-built for climbing and working in an elevated, high-risk environment. Understanding how each feature contributes to this purpose is key to appreciating its design.

The Foundation: Shank and Heel

The most defining feature is the heavy-duty steel shank, a rigid piece of metal embedded in the midsole. This shank distributes the lineman's entire body weight across the arch of the foot, preventing severe fatigue and strain when standing on narrow pole pegs or climbing gaffs for hours.

Paired with this is a distinctly raised heel, typically around 1.5 to 2 inches high. This heel is not for aesthetics; it serves as a critical locking point for climbing gaffs, ensuring the boot remains securely attached to the climbing apparatus.

Unwavering Support: The Tall Shaft

Lineman boots feature a tall shaft, usually between 8 and 10 inches high. This height provides crucial ankle support and stability, reducing the risk of sprains and twists when navigating structures high off the ground.

This snug, high-lacing design ensures the boot moves with the leg, providing confidence and control with every step.

Essential Protection: Safety Toes and EH Rating

Protection from impact and electrical current is non-negotiable. These boots include a steel or composite safety toe to protect against crushing injuries from dropped tools or equipment.

Crucially, they carry an Electrical Hazard (EH) rating. This certification means the sole and heel are constructed with non-conductive materials that can withstand a specific electrical charge, providing a secondary source of protection from accidental electrocution.

All-Conditions Performance: Traction and Weatherproofing

The outsole of a lineman boot features an aggressive tread pattern designed for maximum traction. This grip is essential for maintaining a secure footing on wet, icy, or uneven surfaces like wooden poles and metal tower components.

Most lineman boots also incorporate waterproofing and insulation. These features keep the feet dry and warm, which is critical for safety and focus when working long hours outdoors in unpredictable weather.

Understanding the Trade-offs

The specialized design of a lineman boot creates specific limitations. It is a tool for a specific job, not an all-purpose work boot.

Rigidity vs. Flexibility

The same steel shank that makes the boot excellent for climbing makes it extremely rigid. This stiffness can be cumbersome and fatiguing when walking long distances on flat, solid ground.

Weight and Bulk

The combination of a tall leather shaft, a steel shank, a safety toe, and a heavy-duty outsole makes lineman boots significantly heavier and bulkier than standard work boots.

A Purpose-Built Heel

The raised heel, essential for locking into gaffs, can feel awkward and less stable for general-purpose walking or operating machinery, altering the user's natural gait.

Making the Right Choice for Your Goal

Selecting the correct boot means matching its features directly to the demands of your job.

- If your primary focus is climbing poles and towers: Prioritize a boot with the stiffest steel shank you can find and a prominent, well-defined heel for maximum climbing security.

- If your work involves both climbing and significant groundwork: You must accept the trade-off of a heavier, stiffer boot or consider hybrid models that offer slightly more flexibility at the cost of some climbing support.

- If you primarily work in extreme weather conditions: Ensure the boot has a certified waterproof membrane and the appropriate level of insulation for your climate.

Choosing the right lineman boot is a critical decision that directly impacts your safety, comfort, and performance at height.

Summary Table:

| Key Feature | Purpose | Benefit |

|---|---|---|

| Heavy-Duty Steel Shank | Distributes weight on pegs/gaffs | Reduces foot fatigue, provides stability |

| Raised Heel (1.5-2") | Locks into climbing gaffs | Ensures secure attachment for climbing |

| Tall Shaft (8-10") | Provides ankle support | Prevents sprains, offers stability at height |

| EH-Rated Sole | Protects against electrical hazards | Secondary protection from electrocution |

| Safety Toe (Steel/Composite) | Shields from impact/crushing | Protects feet from dropped tools/equipment |

| Aggressive Tread & Waterproofing | Ensures traction in all weather | Maintains grip on wet/icy surfaces; keeps feet dry |

Need Reliable Lineman Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of specialized boots, including lineman boots engineered for maximum safety, durability, and comfort.

We can provide the exact specifications and volume you require to equip your workforce with confidence. Contact us today to discuss your needs and request a quote.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- What protective functions do industrial-grade safety boots provide in construction and mining? Maximize Worker Safety

- What materials are commonly used in modern work boots for comfort? A Guide to All-Day Support

- What are the cost considerations when choosing between leather and rubber boots for hazmat situations?

- Which professions benefit most from 90-degree heel work boots? Achieve Unmatched Stability on Ladders and Uneven Terrain

- What additional protective footwear feature might be beneficial for construction workers in cold climates? Choose Composite Toe for Superior Warmth

- What protective features do high-performance work boots offer? Expert Guide for Heavy Handling & Climbing Safety

- What type of sole is required for wildland fire boots? The Critical Safety Standard Explained

- What are some tips for measuring and fitting work boots correctly? Ensure All-Day Comfort and Safety