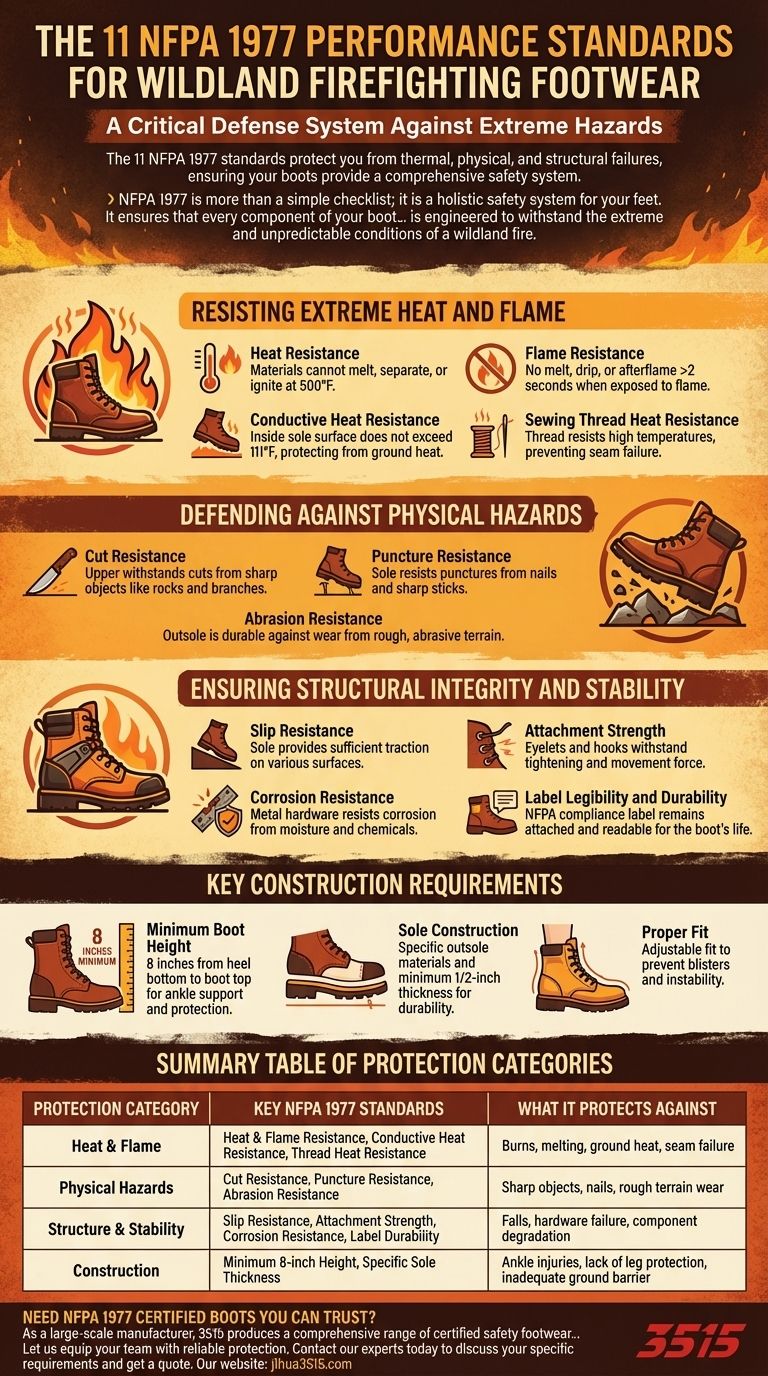

The 11 NFPA 1977 performance standards for wildland firefighting footwear are a critical set of requirements designed to protect you from the unique hazards of the fire line. The key standards include heat and flame resistance, cut and puncture resistance, slip resistance, and specific tests for the durability of components like sewing thread and eyelets. These benchmarks ensure your boots provide a comprehensive defense system against thermal, physical, and structural failure.

NFPA 1977 is more than a simple checklist; it is a holistic safety system for your feet. It ensures that every component of your boot—from the sole to the laces—is engineered to withstand the extreme and unpredictable conditions of a wildland fire.

Why These Standards Matter: A Layered Defense System

Wildland firefighting boots are one of the most critical pieces of your personal protective equipment (PPE). The NFPA 1977 standard establishes minimum performance criteria, ensuring your footwear doesn't become a point of failure. These standards can be grouped into three key areas of protection.

Resisting Extreme Heat and Flame

This is the most obvious and critical function of a fire boot. The standards address heat from every angle to prevent burns and maintain the boot's integrity.

- Heat Resistance: The boot's materials cannot melt, separate, or ignite when exposed to high ambient heat (500°F). This ensures the boot maintains its structure in close proximity to flames.

- Flame Resistance: When directly exposed to flame, the boot material must not melt, drip, or have an afterflame of more than two seconds. This prevents the boot itself from becoming a fuel source and continuing to burn after you've moved away from the fire.

- Conductive Heat Resistance: This test ensures the inside surface of the sole does not exceed 111°F. It protects your feet from the intense heat conducted from the ground, which is a constant and serious threat.

- Sewing Thread Heat Resistance: The thread used to hold the boot together must resist high temperatures. This prevents the boot from falling apart at the seams when exposed to heat.

Defending Against Physical Hazards

The wildland environment is rugged and unpredictable. These standards ensure your boots can withstand the physical abuse of the job.

- Cut Resistance: The upper portion of the boot must be able to withstand cuts from sharp objects like rocks, broken branches, or tools.

- Puncture Resistance: The sole must resist punctures from nails, sharp sticks, and other hazards you might step on, protecting the bottom of your foot.

- Abrasion Resistance: The outsole must be durable enough to withstand wear and tear from walking on rough, abrasive terrain for extended periods.

Ensuring Structural Integrity and Stability

A boot is useless if it falls apart or causes you to lose your footing. These standards guarantee the boot's construction is sound.

- Slip Resistance: The sole must provide sufficient traction on various surfaces, which is critical for maintaining your footing on steep or uneven ground.

- Attachment Strength: The eyelets and hooks used for lacing must be strong enough to withstand the force of tightening and the stress of movement without pulling out.

- Corrosion Resistance: All metal hardware on the boot must resist corrosion from moisture and fire-retardant chemicals, which could otherwise weaken components over time.

- Label Legibility and Durability: The NFPA compliance label must remain attached and readable for the life of the boot. This is essential for accountability and confirming the footwear meets safety standards during inspections.

Key Construction Requirements Beyond Performance

While the 11 performance standards define how a boot must perform under testing, NFPA 1977 also dictates key aspects of its physical construction.

Minimum Boot Height

NFPA 1977 requires a minimum height of 8 inches from the bottom of the heel to the top of the boot. This provides essential ankle support to prevent sprains and protects the lower leg from heat, debris, and snake bites.

Sole Construction

The standard mandates specific outsole materials and a thickness of at least 1/2-inch. This ensures a durable and protective barrier between your foot and the ground.

Proper Fit

While not a testable "performance" standard, the requirement for an adjustable fit is crucial. A boot that fits poorly can cause debilitating blisters and instability, directly impacting your safety and effectiveness on the fire line.

Making the Right Choice for the Fire Line

Use these standards as your guide to ensure you are properly equipped and protected.

- If your primary focus is compliance and safety: Always verify that the boot is explicitly certified to the most current edition of NFPA 1977.

- If your primary focus is durability in rugged terrain: Pay close attention to the sole's construction and abrasion resistance, ensuring it can handle the specific environment you work in.

- If your primary focus is preventing heat-related injury: Prioritize boots that excel in conductive heat resistance, as this directly protects you from ground-level heat during long shifts.

Understanding what each NFPA 1977 standard protects you from empowers you to select the best possible tool for the job.

Summary Table:

| Protection Category | Key NFPA 1977 Standards | What It Protects Against |

|---|---|---|

| Heat & Flame | Heat & Flame Resistance, Conductive Heat Resistance, Thread Heat Resistance | Burns, melting, ground heat, seam failure |

| Physical Hazards | Cut Resistance, Puncture Resistance, Abrasion Resistance | Sharp objects, nails, rough terrain wear |

| Structure & Stability | Slip Resistance, Attachment Strength, Corrosion Resistance, Label Durability | Falls, hardware failure, component degradation |

| Construction | Minimum 8-inch Height, Specific Sole Thickness | Ankle injuries, lack of leg protection, inadequate ground barrier |

Need NFPA 1977 Certified Boots You Can Trust?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure every pair of wildland fire boots meets the rigorous NFPA 1977 standards for heat resistance, durability, and structural integrity.

Let us equip your team with reliable protection. Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Lightweight Tactical Boots Custom Manufacturer for Desert & Combat Use

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What factors determine the durability of construction boots? A Guide to Long-Lasting Work Footwear

- What is the Goodyear Welt construction method? Discover Unmatched Durability & Repairability

- What are the characteristics of harness and engineer boots? Defining Two Iconic Rugged Styles

- What are the different types of PVC boots available? Choose the Right Boot for Your Job

- What types of safety toes are available in mining boots? Choose the Right Protection for Your Mine

- What should be considered when choosing winter work boots? Key Factors for Safety & Warmth

- What types of toe protection are available in work-safe boots? Choose the Right Safety Toe for Your Job

- How can engineer boots be styled in fashion? Master the Art of Rugged Elegance