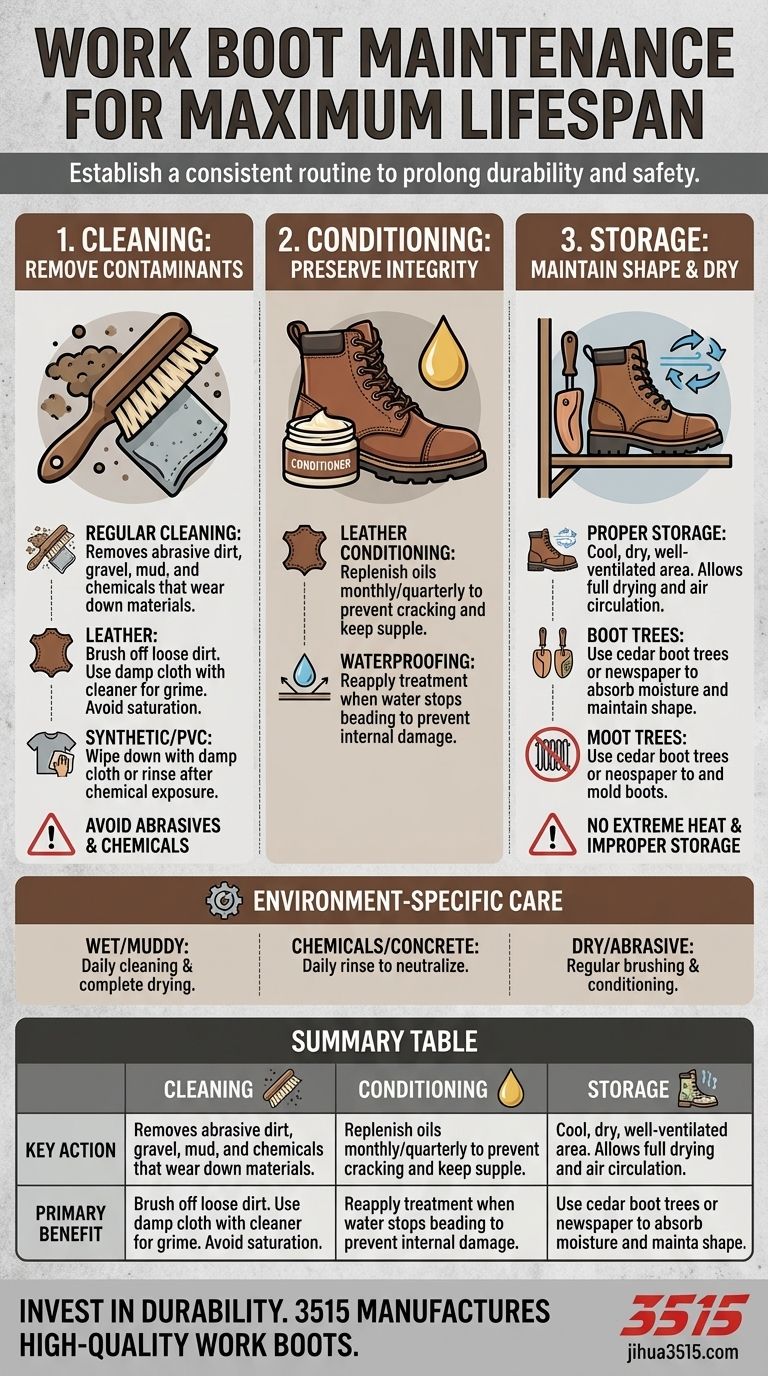

To significantly prolong the life of your work boots, you must adopt a consistent maintenance routine. This involves three core actions: frequent cleaning to remove destructive materials, regular conditioning to keep leather from drying and cracking, and proper storage in a cool, dry place to maintain the boot's shape and allow it to fully dry. These steps work together to preserve structural integrity and functionality.

Effective work boot maintenance is not about occasional deep cleans, but about establishing a consistent routine. This routine shields the materials from their two primary enemies: abrasive contaminants that physically wear them down and moisture imbalance—both too much and too little.

The Foundation: A Consistent Cleaning Regimen

Regular cleaning is the most critical factor in work boot longevity. It's not about aesthetics; it's about removing the elements that actively destroy your boots from the outside in.

Why Cleaning is Non-Negotiable

Dirt, gravel, mud, and job-site chemicals are not benign. These materials are abrasive, grinding away at leather and stitching with every step. Chemicals can directly degrade the boot's materials and compromise waterproofing.

Cleaning Leather Boots

For leather, use a brush to remove loose dirt and debris first. If necessary, use a damp cloth with a specialized leather cleaner for more stubborn grime. Never saturate the leather.

Cleaning Synthetic and PVC Boots

Boots made from synthetic materials like PVC are simpler to maintain. A simple wipe-down with a damp cloth or a rinse after exposure to harsh substances is typically sufficient to remove harmful contaminants.

Preserving Material Integrity and Function

Once clean, the focus shifts to preserving the boot's materials. This means maintaining the right moisture balance in leather and ensuring the boot's protective barriers remain intact.

The Role of Conditioning for Leather

Leather is a natural material that contains oils. Over time, these oils dry out, causing the leather to become brittle, stiff, and prone to cracking.

Applying a leather conditioner or oil every few months (or monthly for boots in extreme conditions, like for firefighters) replenishes these oils. This keeps the leather supple, strong, and resistant to damage from flexing.

Maintaining Waterproofing

Most work boots have a waterproofing treatment that wears down over time. If you notice water is beginning to soak into the material rather than beading off, it's time to reapply a suitable waterproofing product. This is essential for both comfort and preventing water damage to the boot's internal structure.

Common Pitfalls to Avoid

Even with the best intentions, common mistakes can shorten your boots' lifespan as much as outright neglect. Understanding these pitfalls is crucial.

The Danger of Extreme Heat

Never dry your boots next to a radiator, fire, or with any other direct heat source. This rapidly draws moisture out of the leather, causing it to crack and warp. It can also damage adhesives used in the sole.

Improper Storage

Tossing wet boots in a closet or a pile is a recipe for disaster. This traps moisture, promoting the growth of mildew and bacteria which breaks down materials and creates odor. It also causes the boots to lose their supportive shape.

The Final Step: Proper Storage

How you store your boots between shifts has a significant impact on their durability. The goal is to allow them to dry completely while maintaining their intended form.

Why Storage Matters

Proper storage allows air to circulate, which is essential for drying out sweat and environmental moisture. It also prevents the boots from being crushed, which helps maintain the ankle support and overall structure you rely on.

Best Practices for Storage

Always store your boots in a cool, dry, well-ventilated area. To help them maintain their shape and absorb internal moisture, insert cedar boot trees. If you don't have boot trees, loosely stuffing them with newspaper is an effective alternative.

Applying This to Your Work Environment

Your specific maintenance frequency will depend on your job site's conditions. Tailor your routine to the challenges your boots face daily.

- If your primary focus is working in wet or muddy conditions: Prioritize daily cleaning and ensure boots dry completely between wears to prevent material rot.

- If your primary focus is working around chemicals or concrete: A daily rinse is critical to neutralize corrosive substances before they can cause damage.

- If your primary focus is working in dry, abrasive environments: Emphasize regular brushing to remove grit and consistent leather conditioning to combat cracking.

Consistent care transforms your boots from a disposable tool into a durable, long-term investment in your safety and comfort.

Summary Table:

| Maintenance Step | Key Action | Primary Benefit |

|---|---|---|

| Cleaning | Brush off dirt; use damp cloth/cleaner | Removes abrasive contaminants that wear down materials |

| Conditioning | Apply leather conditioner/oil every few months | Keeps leather supple, prevents cracking and brittleness |

| Storage | Store in cool, dry place; use boot trees/newspaper | Maintains shape, allows full drying, prevents mildew |

Invest in Durability from the Start

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality work boots and footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, built with durable materials designed to withstand harsh conditions.

Let us help you provide your customers with reliable, long-lasting footwear that reduces replacement costs and enhances safety.

Contact us today to discuss your work boot manufacturing needs and explore our product range.

Visual Guide

Related Products

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

People Also Ask

- What are the advantages of engineer boots? Superior Durability & a Secure Fit for Demanding Use

- What types of protection do composite toe work boots offer? Essential Safety for Modern Workplaces

- What features should surveyors look for in work boots? Essential Durability, Traction & Protection

- How should one choose the right engineer boots? A Guide to Fit, Material, and Purpose

- What are some common work-related injuries that work boots can help prevent? Secure Your Workforce Today

- What does metatarsal protection in ASTM standards involve? Essential Guide to Instep Safety

- What is the purpose of a shank in work boots? Unlock the Secret to All-Day Foot Support

- What are the main types of materials used for work boot uppers? A Guide to Leather, Synthetics & Rubber