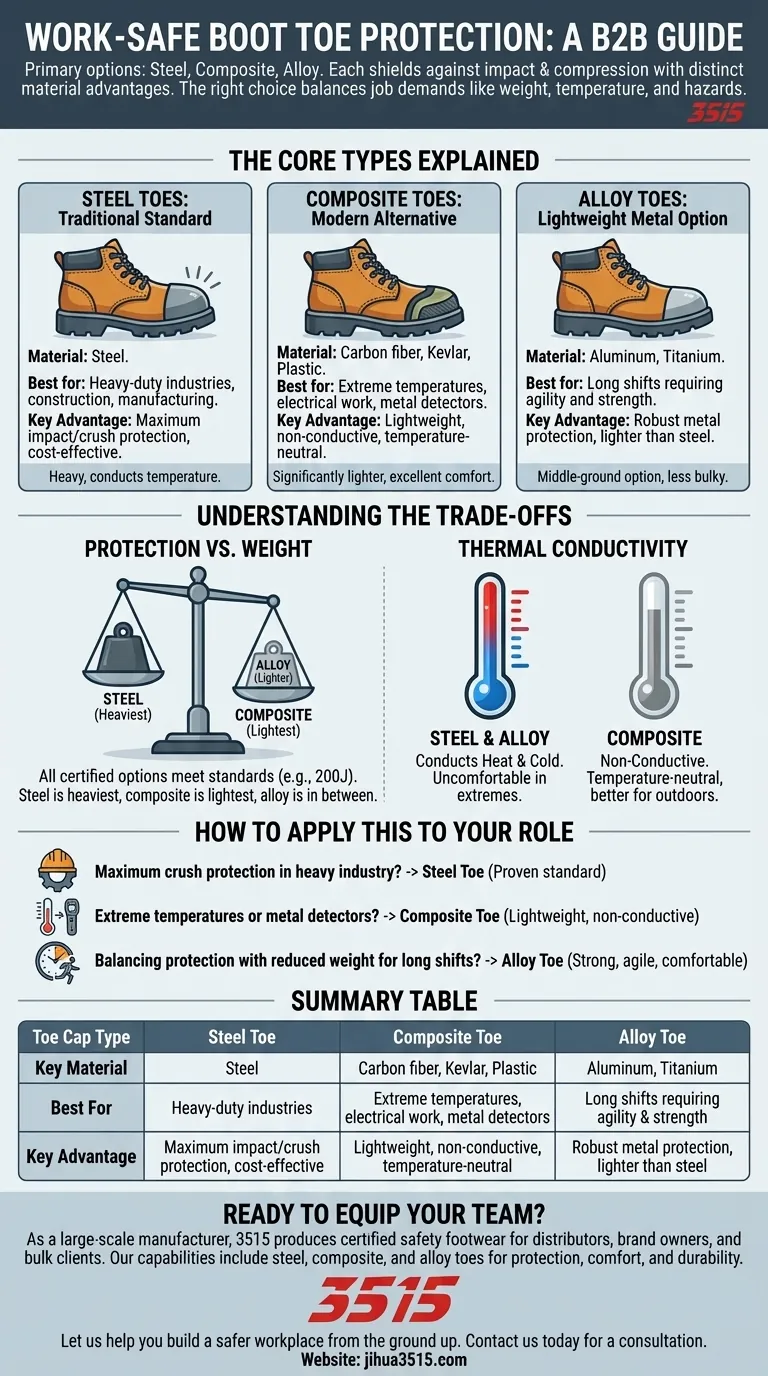

When selecting work-safe boots, your primary options for toe protection are steel, composite, and alloy caps. Each is designed to shield your feet from impact and compression hazards, but they achieve this with different materials, resulting in distinct advantages for specific work environments. While steel is the traditional standard, modern materials offer lighter, non-metallic alternatives without compromising on safety standards.

The decision is not about which toe cap is "safest," as all certified options meet rigorous standards. Instead, the right choice depends on balancing the specific demands of your job—such as weight, temperature exposure, and electrical hazards—against the properties of each material.

The Core Types of Safety Toes Explained

Understanding the fundamental differences between the main types of protective toe caps is the first step in choosing the right boot. Each material offers a unique combination of benefits.

Steel Toes: The Traditional Standard

Steel toes are the classic choice for heavy-duty protection. They are engineered to prevent injury from heavy falling objects, rolling equipment, or sharp tools, making them a staple in construction and manufacturing.

Their primary strength is providing maximum protection against impact and compression at a cost-effective price point.

Composite Toes: The Modern Alternative

Composite toes are made from non-metallic materials like carbon fiber, plastic, or Kevlar. This construction makes them significantly lighter than steel.

Because they don't conduct electricity, they are an excellent choice for electricians. They also don't transfer cold or heat, making them more comfortable for anyone working outdoors in extreme temperatures.

Alloy Toes: The Lightweight Metal Option

Alloy toes are crafted from a mix of metals, most commonly aluminum or titanium. They provide the impact resistance of a metal cap while being noticeably lighter than traditional steel.

This makes them a great middle-ground option, offering robust protection in a less bulky and more agile design that helps reduce foot fatigue over a long day.

Understanding the Trade-offs

Choosing a safety toe involves more than just picking a material; it requires weighing the practical advantages and disadvantages of each option against your daily work realities.

Protection vs. Weight

While all certified safety toes meet the same impact standards (typically 200 joules), their weight differs significantly.

Steel is the heaviest, which can contribute to fatigue. Alloy toes are lighter than steel, and composite toes are the lightest of all, offering comparable protection with the least amount of bulk.

Thermal Conductivity

Metal is an excellent conductor of temperature. This means steel and alloy toes can become uncomfortably cold in winter environments or hot in extreme heat.

Composite toes, being non-metallic, do not conduct temperature, providing a significant comfort advantage for outdoor workers or those in refrigerated facilities.

Workplace Environment

The specific rules of your workplace can dictate the best choice. For environments with metal detectors, like airports or secure facilities, non-metallic composite toes allow you to pass through without issue.

Furthermore, for electricians or those working around live circuits, the non-conductive properties of composite materials are a critical safety feature.

How to Apply This to Your Role

Your job function is the ultimate guide. Use these points to match the right toe protection to your specific needs.

- If your primary focus is maximum crush protection in heavy industry or construction: A steel toe is the proven, cost-effective standard for deflecting extreme force.

- If your primary focus is working in extreme temperatures or passing through metal detectors: A composite toe offers excellent, lightweight protection without conducting heat, cold, or electricity.

- If your primary focus is balancing strong protection with reduced weight for long shifts: An alloy toe delivers the strength of metal in a lighter, more comfortable package.

Choosing the right toe protection is the first step in building a foundation of safety from the ground up.

Summary Table:

| Toe Cap Type | Key Material | Best For | Key Advantage |

|---|---|---|---|

| Steel Toe | Steel | Heavy-duty industries (construction, manufacturing) | Maximum impact/crush protection, cost-effective |

| Composite Toe | Carbon fiber, Kevlar, Plastic | Extreme temperatures, electrical work, metal detectors | Lightweight, non-conductive, temperature-neutral |

| Alloy Toe | Aluminum, Titanium | Long shifts requiring agility and strength | Robust metal protection, lighter than steel |

Ready to Equip Your Team with the Perfect Safety Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes with steel, composite, and alloy toes, ensuring you get the right protection, comfort, and durability for your specific workforce needs.

Let us help you build a safer workplace from the ground up.

Contact us today for a consultation to discuss your requirements and explore our extensive catalog.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What design considerations are common to both structural and wildland fire boots? Safety, Ergonomics & Standards

- Are engineer boots the only type of boots motorcyclists wear today? Explore the Best Modern Choices

- What are the key features of workwear boots? A Guide to Certified Safety and Durability

- What is the proper way to clean work boots? Extend Boot Life with Gentle Cleaning

- What maintenance tips should be followed for farm boots? Extend Their Lifespan & Protect Your Feet

- What are the historical significance and modern adaptations of cowboy boots? From Ranch Work to Modern Worksite

- What work boot features are essential for farming and agricultural work? Complete Protection Guide

- What types of outsoles are available for different work environments? Choose the Right Grip for Your Job