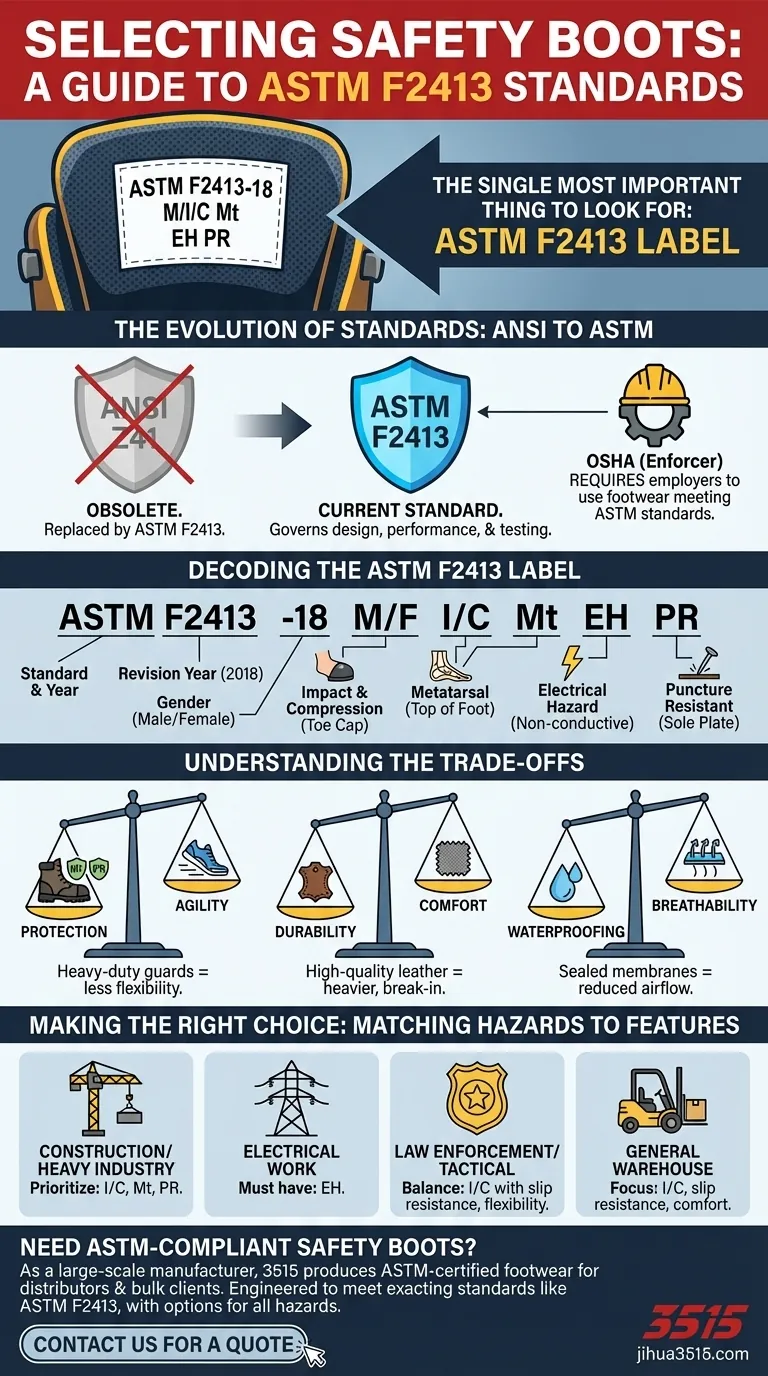

The single most important thing to look for when selecting safety boots is the ASTM F2413 label inside the tongue. While many people still refer to the old ANSI Z41 standard, it was withdrawn and replaced by ASTM F2413. This label is your guarantee that the footwear meets current, rigorous benchmarks for performance and safety as required by regulatory bodies like OSHA.

The goal is not simply to find a boot that meets "a" standard, but to understand the specific protection codes on the ASTM label and match them to the actual hazards present in your work environment.

The Standards That Matter: ANSI, ASTM, and OSHA

Understanding how safety standards work is the first step to making an informed choice. The different acronyms can be confusing, but they serve distinct and complementary roles.

The Old Standard: ANSI Z41

The American National Standards Institute (ANSI) previously published the Z41 standard for protective footwear. This standard is now obsolete and has been replaced. If a boot is only marked as ANSI Z41 compliant, it is likely old stock and does not meet the most current testing requirements.

The Current Standard: ASTM F2413

The American Society for Testing and Materials (ASTM) now governs the standards for safety footwear. The key standard is ASTM F2413, which outlines the minimum requirements for design, performance, testing, and classification. A boot must meet this standard to be considered legitimate safety footwear in the United States.

The Enforcer: OSHA

The Occupational Safety and Health Administration (OSHA) is the government agency that sets and enforces workplace safety regulations. OSHA doesn't create the footwear standards, but it requires employers to ensure their employees wear footwear that complies with a standard like ASTM F2413 in hazardous environments.

Decoding the ASTM F2413 Label

The ASTM label isn't a simple pass/fail mark. It contains a line of codes that tells you exactly what hazards the boot is designed to protect against. Learning to read this is critical.

A typical label might read: ASTM F2413-18 M/I/C Mt EH PR

Line 1: The Standard

The first line simply identifies the standard (ASTM F2413) and the year of its revision (-18 for 2018).

Line 2: The Codes

This is the most important part. It identifies the gender the boot is designed for (M for Male or F for Female) and lists the specific protections it offers.

- I/C (Impact and Compression): This is the core of any safety boot. It means the toe cap has been tested to protect against specific levels of impact (falling objects) and compression (rolling objects). This is a mandatory part of the standard.

- Mt (Metatarsal): This indicates the boot has an integrated guard that protects the top of your foot (the metatarsal bones) from impact. This is crucial in environments with significant drop hazards.

- EH (Electrical Hazard): This footwear is made with non-conductive, shock-resistant soles and heels. It provides a secondary source of protection on dry surfaces from open electrical circuits.

- PR (Puncture Resistant): These boots have a puncture-resistant plate built into the sole to protect your foot from sharp objects like nails or scrap metal.

Understanding the Trade-offs

Choosing the right features always involves balancing competing needs. A boot that maximizes one type of protection may compromise on another factor.

Protection vs. Agility

A boot with metatarsal guards and heavy-duty puncture plates offers incredible protection. However, it will also be heavier and less flexible than a standard safety-toe boot, which can be a factor in jobs requiring constant movement or climbing.

Durability vs. Comfort

High-quality, full-grain leather offers maximum durability and protection from fluids and chemicals. However, it can be heavy and require a break-in period. Lighter, synthetic materials may offer more out-of-the-box comfort and breathability but may not stand up to the same level of abuse.

Waterproofing vs. Breathability

A fully waterproof membrane is essential for wet conditions. The trade-off is often reduced breathability, which can lead to sweaty, uncomfortable feet in hot environments. Materials must be chosen based on your primary work climate.

Making the Right Choice for Your Goal

Ultimately, the best boot is the one that correctly matches your specific job hazards and daily tasks.

- If your primary focus is construction or heavy industry: You must prioritize boots with high impact and compression ratings (I/C), and strongly consider metatarsal (Mt) and puncture resistance (PR).

- If your primary focus is electrical work: An Electrical Hazard (EH) rating is non-negotiable and should be your first consideration after the basic safety toe.

- If your primary focus is law enforcement or tactical response: Balance a safety toe (I/C) with features not on the label, such as slip resistance, flexibility, and lightweight materials for mobility.

- If your primary focus is general warehouse or manufacturing work: A standard I/C-rated boot with excellent slip resistance and comfort for standing on hard surfaces is likely the best fit.

By looking past the marketing and learning to read the ASTM label, you can confidently select footwear that provides proven protection for the real risks you face.

Summary Table:

| Key Factor | What to Look For | Why It Matters |

|---|---|---|

| Primary Standard | ASTM F2413 label inside the tongue | Replaces the obsolete ANSI Z41; ensures compliance with current OSHA regulations. |

| Core Protection | I/C (Impact/Compression) rating | Mandatory for basic toe protection against falling or rolling objects. |

| Additional Hazards | Codes like Mt (Metatarsal), EH (Electrical Hazard), PR (Puncture Resistant) | Match these to your job's specific risks (e.g., EH for electricians, PR for construction). |

| Trade-offs | Balance protection, agility, durability, and comfort | Heavy-duty boots offer more safety but may be less flexible; choose based on your tasks. |

Need ANSI-compliant safety boots tailored to your hazards? As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified footwear for distributors, brand owners, and bulk clients. Our boots are engineered to meet exacting standards like ASTM F2413, with options for impact resistance, electrical hazard protection, and more—ensuring your team stays safe and productive. Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Sport Style Safety Boots for Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- How do environmental conditions influence the choice of PVC work boots? Match Your Boot to Your Worksite

- What features should workers in muddy conditions look for in work boots? | The Ultimate Guide

- What features enhance fit, comfort, and support in work boots? Essential Guide for Distributors & Bulk Buyers

- What is the ideal time to waterproof work boots? A Proactive Guide for Year-Round Dry Feet

- How should cowboy boots be maintained for farm work? A Practical Guide to Extend Their Lifespan

- What factors determine the durability of construction boots? A Guide to Long-Lasting Work Footwear

- What materials are used for work boot outsoles? Choose the Right Material for Your Job

- What are the signs that work boots need replacement? Protect Your Feet and Safety on the Job