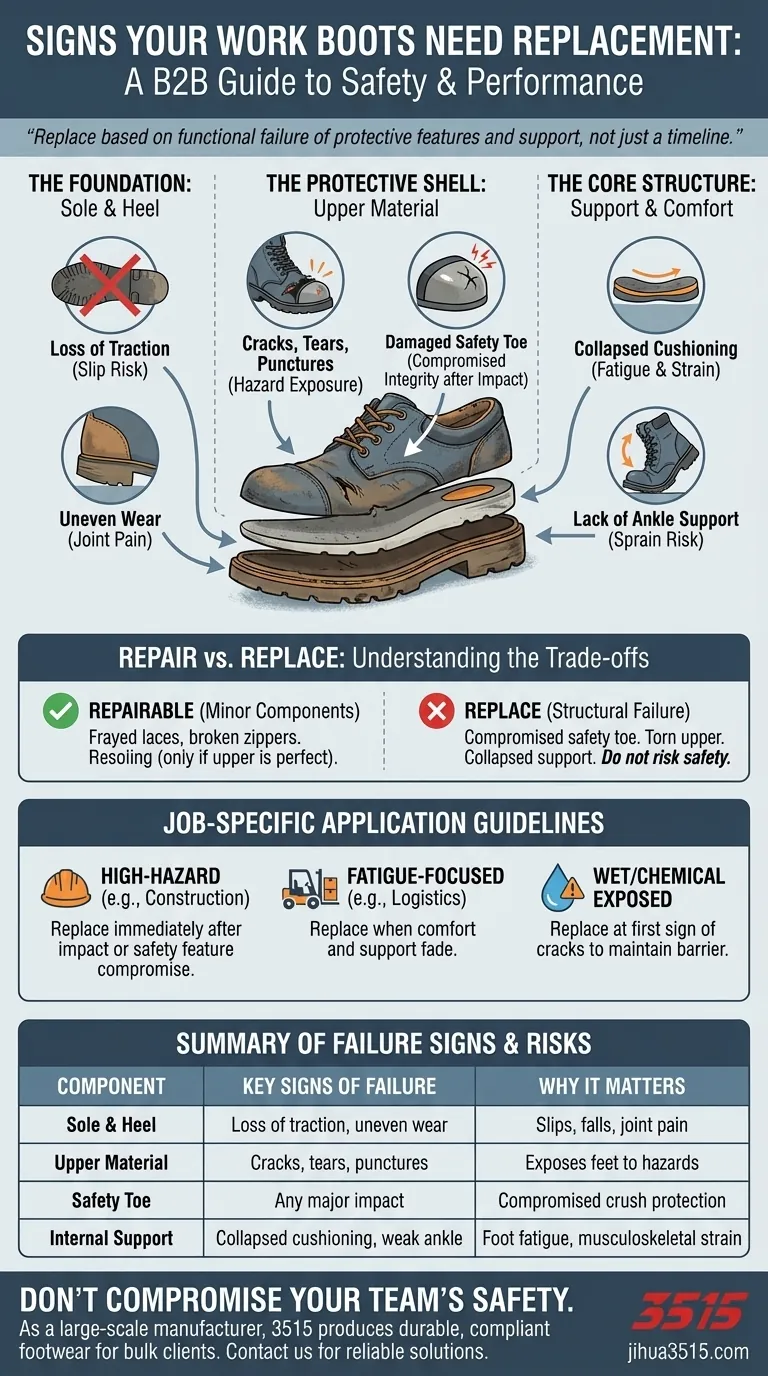

The clearest signs your work boots need replacement are visible damage to their core safety and support components. This includes heavily worn or uneven soles that have lost their tread, cracks or tears in the upper material, and a noticeable lack of cushioning or support that leaves your feet sore after a shift.

Your work boots are a critical piece of safety equipment. You should base the decision to replace them on the functional failure of their protective features and support systems, not just a predetermined timeline.

The Foundation: Assessing the Sole and Heel

The sole of your boot is your primary point of contact with your work surface. Its failure directly compromises your stability and safety.

Loss of Traction

Think of your boot's sole like the tire tread on a car. As the patterns wear down and become smooth, the boot loses its ability to grip surfaces, significantly increasing your risk of slips and falls, especially in wet or oily conditions.

Uneven Wear

If you notice one side of the heel or sole is worn down much more than the other, it's a red flag. This indicates the boot's internal support structure has failed, which can alter your gait and lead to long-term joint pain in your ankles, knees, and back.

The Protective Shell: Inspecting the Upper Material

The upper part of the boot shields you from impacts, punctures, and environmental hazards. Breaches in this shell are not cosmetic issues; they are safety failures.

Cracks, Tears, and Punctures

Deep cracks in the leather or tears in the fabric eliminate any waterproofing and expose your feet to potential chemical, liquid, or electrical hazards. Any visible puncture means the boot's protective barrier has been compromised and it must be replaced.

Damaged Safety Toes

Safety toes (steel, composite, or alloy) are designed to withstand a single, significant impact. If your boot suffers a heavy blow that could have damaged the toe cap, it must be replaced, even if there is no visible dent. Its structural integrity is gone.

The Core Structure: When Support and Comfort Fail

A work boot's job extends beyond just protecting you from external threats. It must also provide the internal support needed to prevent fatigue and musculoskeletal strain over a long day.

Collapsed Cushioning

If the boot's insole or midsole has compressed to the point where it feels like you are standing on hard ground, the shock absorption is gone. This lack of cushioning sends stress directly into your feet, legs, and lower back.

Lack of Ankle Support

Over time, the materials that form the structure of the boot will soften and break down. If you can easily bend and twist the boot in ways you couldn't when it was new, it will no longer provide the ankle support needed to prevent sprains and twists.

Understanding the Trade-offs: Repair vs. Replace

Knowing when a boot can be saved versus when it must be retired is key to ensuring both safety and value.

What Can Be Repaired

Minor components can often be fixed to extend a boot's life. Frayed laces and broken zippers are simple replacements. A professional cobbler can sometimes replace a worn-out sole, a process known as resoling, but only if the boot's upper is still in excellent condition.

When Replacement is Non-Negotiable

Repairs cannot fix fundamental structural failure. If the safety toe is compromised, the internal support has collapsed, or the upper material is cracked and torn, replacement is the only safe option. Attempting to repair critical safety features is a risk you should not take.

How to Apply This to Your Work

While a general guideline is to replace boots every 6 to 12 months, your specific job conditions are a more important factor.

- If you work in a high-hazard environment (e.g., construction, manufacturing): Prioritize the integrity of safety features, replacing boots immediately after any major impact or at the first sign of a compromised toe cap or punctured sole.

- If your primary focus is preventing fatigue (e.g., warehousing, logistics): Focus on the breakdown of cushioning and support, replacing boots as soon as they no longer feel comfortable and supportive for a full shift.

- If you work in wet or chemical-exposed conditions: Immediately replace boots that show any cracks or tears in the upper material to maintain their protective, waterproof barrier.

Ultimately, trust the physical evidence your boots provide; your safety and daily comfort depend entirely on their performance.

Summary Table:

| Safety Component | Key Signs of Failure | Why It Matters |

|---|---|---|

| Sole & Heel | Loss of traction, uneven wear | Prevents slips, falls, and joint pain |

| Upper Material | Cracks, tears, or punctures | Exposes feet to hazards and liquids |

| Safety Toe | Any major impact (even if no dent is visible) | Compromised protection from crushing injuries |

| Internal Support | Collapsed cushioning, weak ankle support | Leads to foot fatigue and musculoskeletal strain |

Don't let worn-out work boots put your safety at risk. As a large-scale manufacturer, 3515 produces a comprehensive range of durable and safety-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots designed for maximum protection and comfort. Ensure your team is equipped with reliable footwear—contact us today to discuss your needs and get a quote!

Visual Guide

Related Products

- Wholesale Durable 6-Inch Work Boots | Custom & Private Label Manufacturer

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are signs that work boots need replacement? Don't Risk Your Safety on Worn-Out Footwear

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health