At its core, the durability of a construction boot is determined by three critical factors: its construction method, the quality of its materials, and the robustness of its hardware. The most durable boots feature a stitched-on sole, are made from high-grade leather with reinforcements, and use hardware that can withstand daily abuse.

The truest measure of a boot's durability is not a single feature, but how its construction, materials, and design work together to meet the specific demands of your job site. A boot designed for longevity is an integrated system, not just a collection of parts.

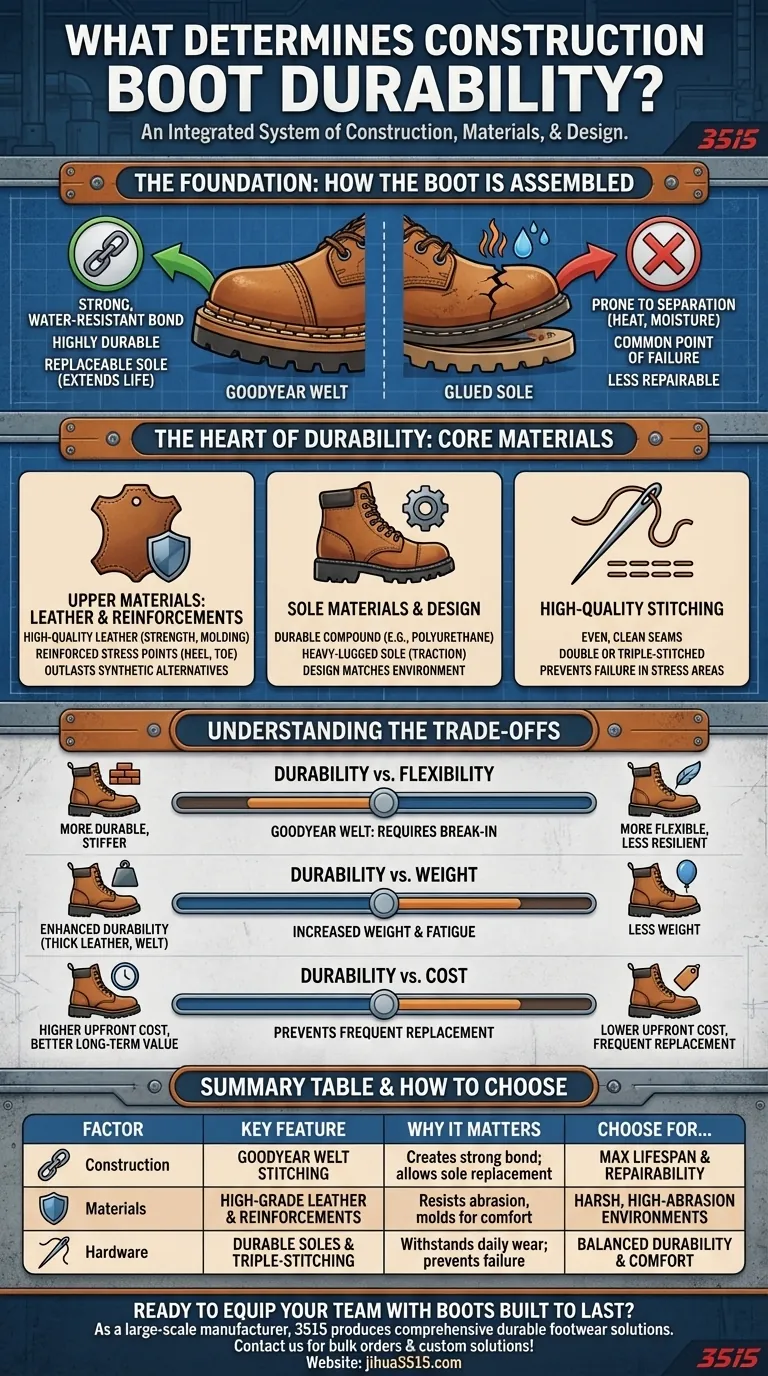

The Foundation: How the Boot is Assembled

The method used to attach the sole to the upper is the single most important factor in a boot's lifespan and repairability.

The Gold Standard: Goodyear Welt

A Goodyear welt is a method where a strip of leather (the "welt") is stitched to the boot's upper and then stitched to the outsole. This creates an incredibly strong, water-resistant bond.

This construction makes the boot highly durable and allows for the sole to be replaced multiple times by a cobbler, significantly extending the boot's life.

Other Stitched Constructions

Methods like the Blake stitch also attach the sole with stitching, offering good durability and more flexibility than a Goodyear welt. The key principle is that the sole is physically stitched, not just glued.

The Common Point of Failure: Glued Soles

Many less-durable boots have soles that are simply glued on. This bond is prone to separating with heat, moisture, and constant flexing, making it the most common reason boots fail prematurely.

The Heart of Durability: Core Materials

The materials used for the upper, lining, and sole directly impact how well the boot withstands abrasion, moisture, and stress.

Upper Materials: Leather and Reinforcements

High-quality leather remains the top choice for durable uppers due to its strength and ability to mold to the foot. Look for reinforcements at key stress points, like the heel and toe.

While synthetic materials or textile combinations can offer benefits like reduced weight, a quality leather-lined boot will almost always outlast a fully synthetic alternative.

Sole Materials and Design

The sole must be made from a durable compound like polyurethane that resists wear and tear. The design is equally important.

A heavy-lugged sole is essential for traction on uneven outdoor sites, while a sleeker design may be sufficient for urban or indoor work. The sole must match the environment.

The Importance of High-Quality Stitching

Beyond the sole attachment, look at the stitching on the upper itself. Seams should be even, clean, and preferably double or triple-stitched, especially in high-stress areas.

Understanding the Trade-offs

Durability rarely exists in a vacuum. Understanding the compromises is key to selecting the right boot.

Durability vs. Flexibility

The most durable construction methods, like a Goodyear welt, often result in a stiffer boot that requires a break-in period. More flexible constructions may sacrifice some long-term resilience.

Durability vs. Weight

Features that enhance durability—such as thick leather, welt construction, and heavy-duty soles—also add weight. This can lead to fatigue over a long workday.

Durability vs. Cost

There is a direct correlation between price and durability. High-quality materials and labor-intensive construction methods cost more upfront but prevent the need for frequent replacement, offering better long-term value.

How to Choose a Boot That Lasts

Choosing the right boot means aligning its features with your specific work demands.

- If your primary focus is maximum lifespan and repairability: Prioritize boots with a Goodyear welt construction and full-grain leather uppers.

- If your primary focus is working in harsh, high-abrasion environments: Focus on boots with reinforced stress points, triple-stitching, and a purpose-built sole designed for your specific surfaces.

- If your primary focus is balancing durability with all-day comfort: Consider a quality stitched construction like a Blake stitch and look for premium materials that offer both strength and flexibility.

Ultimately, a durable boot is one whose construction is perfectly matched to the challenges it will face every day.

Summary Table:

| Factor | Key Feature | Why It Matters |

|---|---|---|

| Construction | Goodyear Welt Stitching | Creates a strong, water-resistant bond; allows for sole replacement. |

| Materials | High-Grade Leather & Reinforcements | Resists abrasion, moisture, and stress; molds to the foot for comfort. |

| Hardware | Durable Soles & Stitching | Withstands daily wear; triple-stitched seams prevent failure at stress points. |

Ready to equip your team with boots built to last? As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots, including those with Goodyear welt construction and premium materials designed for harsh environments. Let us help you find the perfect balance of durability, comfort, and value. Contact us today for a custom solution!

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?

- What are the primary protective roles of safety shoes for mosquito control? Safeguard Workers from Chemical & Field Risks

- What are heavy duty work boots designed for? Maximum Protection for Hazardous Work Environments

- Is there a downside to steel toe boots? Weighing Protection Against Daily Comfort

- Why are safety boots with steel toes mandatory for logging? Ultimate Protection Against Heavy Impact Hazards