Ultimately, the specific environment dictates the necessary features of a PVC work boot. Your choice should be guided primarily by the temperature, moisture levels, and chemical hazards you will face, as these factors directly impact your safety, comfort, and the footwear's durability.

The most common mistake is choosing a boot based on price or appearance. To make an effective choice, you must shift your focus to the material properties of the boot and match them directly to the demands of your specific work environment.

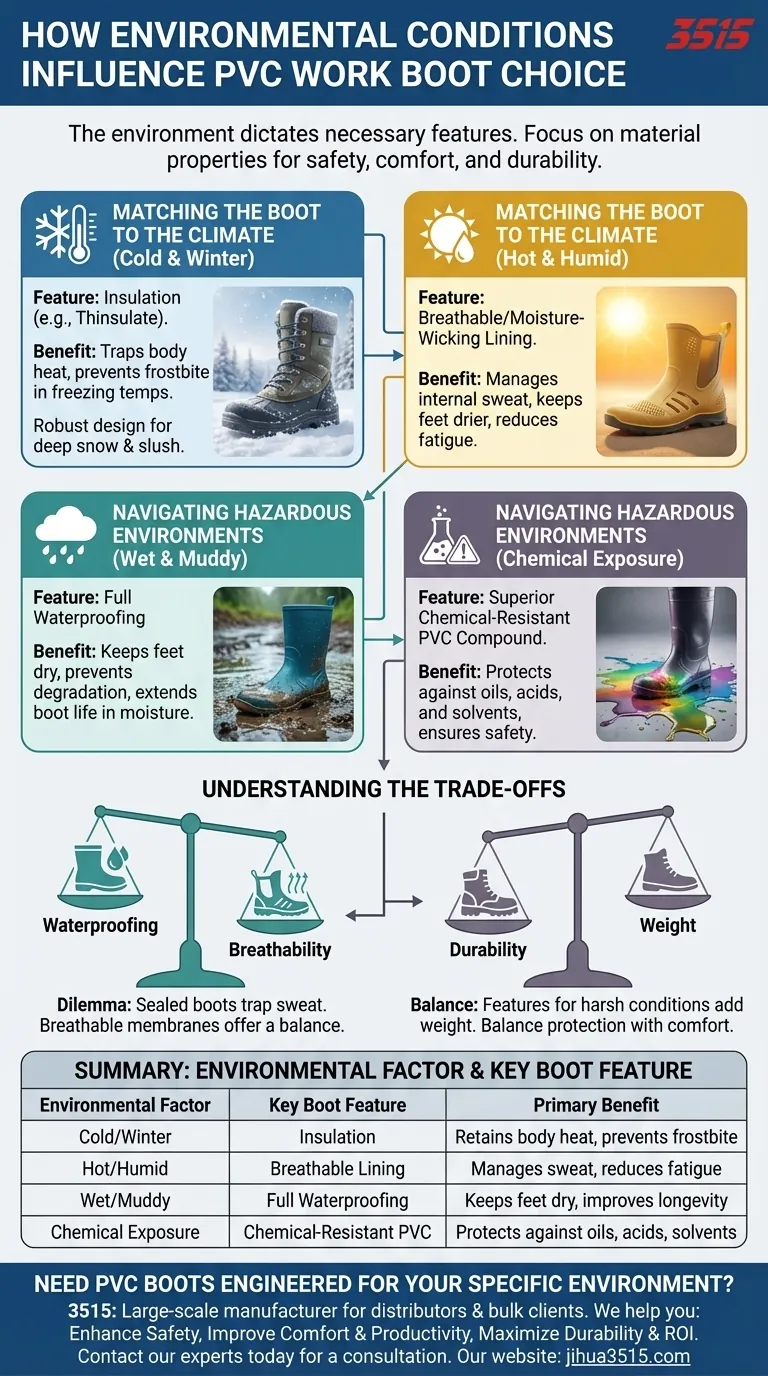

Matching the Boot to the Climate

The ambient temperature and weather patterns of your worksite are the first critical filters for selecting the right footwear. A boot designed for one climate can be ineffective or even uncomfortable in another.

For Cold and Winter Conditions

In cold climates, insulation is non-negotiable. Materials like Thinsulate are integrated into boots to trap air and keep your feet warm, preventing heat loss in freezing temperatures.

Harsh winter conditions involving deep snow, slush, and road salt will accelerate the wear and tear on any boot. A robust, well-sealed design is critical for longevity.

For Hot and Humid Conditions

In hot weather, the primary challenge is managing internal moisture from sweat. Look for boots that feature breathable construction or moisture-wicking linings.

These features help pull sweat away from the skin, keeping your feet drier and more comfortable throughout the day. Lightweight boots are also heavily preferred to reduce fatigue in the heat.

Navigating Hazardous Work Environments

Beyond general climate, the specific hazards present on the ground—from standing water to chemical spills—demand specialized protection.

For Wet and Muddy Terrain

For any environment with significant moisture or mud, waterproofing is the most essential feature. It is the only reliable way to keep your feet dry and healthy.

Waterproof boots are also proven to last longer in consistently wet conditions when compared to non-waterproof alternatives, which can degrade more quickly.

For Chemical Exposure

If your work involves exposure to chemicals, oils, or acids, you must prioritize boots made from a superior chemical-resistant PVC compound.

Not all PVC is formulated the same. A standard boot may offer water resistance but can quickly break down when exposed to harsh chemicals, compromising your safety.

Understanding the Trade-offs

Selecting the perfect boot often involves balancing competing features. Understanding these compromises is key to making an informed decision.

The Waterproofing vs. Breathability Dilemma

A completely sealed, waterproof boot is excellent at keeping water out, but it can also trap sweat in. In hot climates, this can lead to discomfort.

This is why some boots are designed with breathable membranes—they attempt to block external water while allowing internal vapor to escape, though a trade-off in absolute waterproofing can exist.

The Durability vs. Weight Balance

Features that enhance durability in harsh conditions, such as thicker soles, insulation, and chemical-resistant compounds, inevitably add weight.

While necessary for safety, this extra weight can increase fatigue over a long workday. You must balance the required level of protection with the need for comfort and mobility.

Making the Right Choice for Your Environment

Your final decision should be a direct response to your most common working conditions.

- If your primary focus is cold and wet weather: Prioritize a fully waterproof boot with a dedicated insulation layer to ensure warmth and dryness.

- If your primary focus is chemical safety: Verify the boot is specifically rated for chemical resistance, as standard PVC may not offer adequate protection.

- If your primary focus is working in heat: Seek out lighter-weight boots that explicitly mention breathable or moisture-wicking linings to manage sweat.

By analyzing your environment first, you ensure the boot you choose will perform as an essential piece of safety equipment.

Summary Table:

| Environmental Factor | Key Boot Feature | Primary Benefit |

|---|---|---|

| Cold/Winter Conditions | Insulation (e.g., Thinsulate) | Retains body heat, prevents frostbite |

| Hot/Humid Conditions | Breathable/Moisture-Wicking Lining | Manages sweat, reduces fatigue and discomfort |

| Wet/Muddy Terrain | Full Waterproofing | Keeps feet dry, prevents degradation, improves longevity |

| Chemical Exposure | Superior Chemical-Resistant PVC Compound | Protects against oils, acids, and solvents for maximum safety |

Need PVC work boots engineered for your specific environment?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of chemical-resistant, insulated, waterproof, and breathable PVC boots designed to meet the exact demands of your worksite.

We help you:

- Enhance Worker Safety: With boots specifically formulated for your unique hazards.

- Improve Comfort & Productivity: By matching boot features to your climate, reducing fatigue.

- Maximize Durability & ROI: Ensuring your footwear investment lasts in challenging conditions.

Let's discuss your requirements and get you a solution that fits perfectly. Contact our experts today for a consultation

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- Why are puncture-resistant Wellington boots important? The Ultimate Defense Against Unseen Hazards

- What are three key reasons to wear insulated work boots in winter? Essential Protection for Cold Work

- Are PVC boots used in outdoor work involving wet terrain? A Guide to Choosing the Right Work Boot

- What are the characteristics of lineman boots? Essential Safety & Support for Utility Workers

- How is all-around comfort achieved in western boots? Discover the Integrated Comfort System

- What features should concrete workers look for in work boots? Essential Protection for Harsh Environments

- What are the key parts of a boot's anatomy? A Guide to Superior Support and Durability

- What are the benefits of work boots for women? Safety, Comfort & Durability Explained