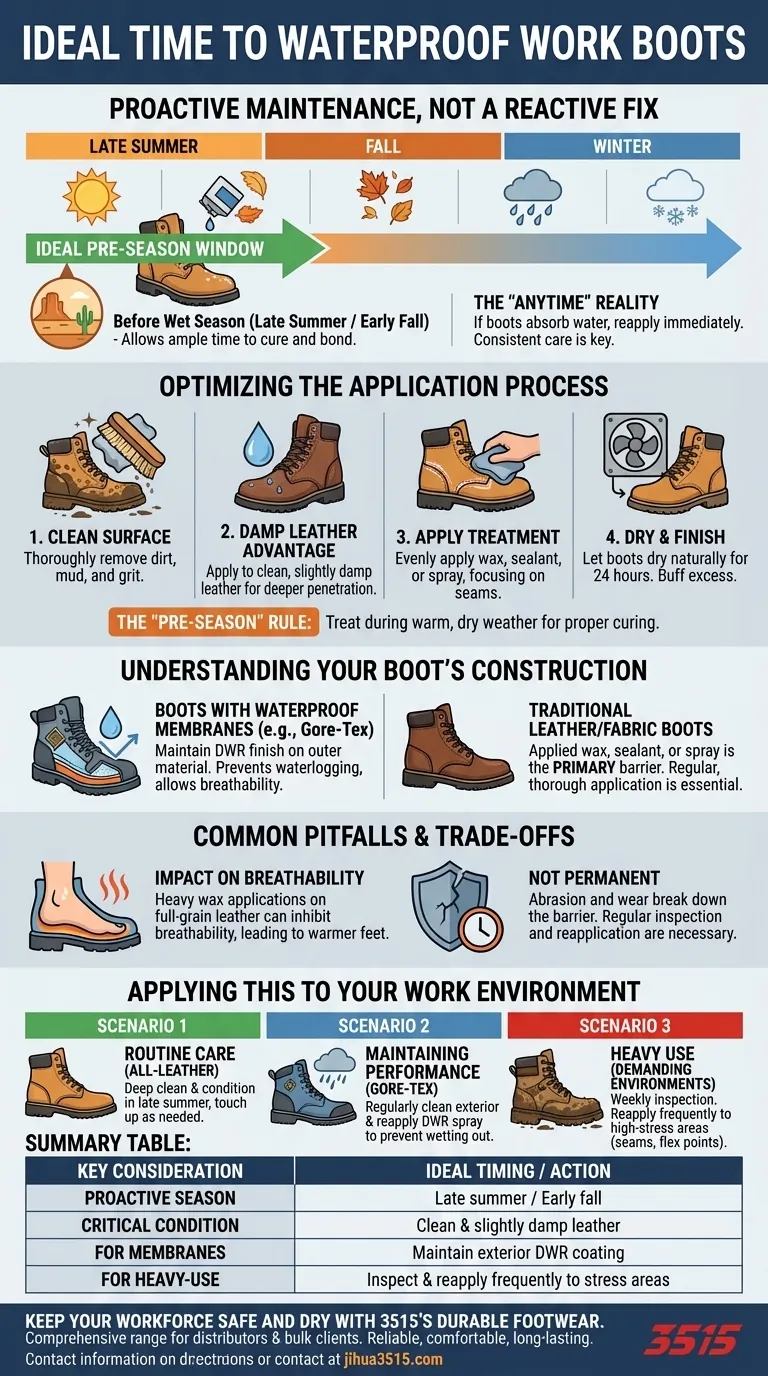

The ideal time to waterproof your work boots is before the wet season begins, typically in late summer or early fall. This proactive approach ensures the protective sealant has ample time to cure and bond with the material, preparing your boots for the harsh conditions of rain, mud, and snow.

The specific time of year is less critical than the underlying principle: waterproofing is a proactive maintenance task, not a reactive fix. For maximum effectiveness, the treatment must be applied to clean, slightly damp boots to ensure it fully penetrates and protects the material from the inside out.

Why Proactive Waterproofing is Essential

Treating your boots should be part of a regular maintenance schedule, not an emergency measure taken the night before a storm. This approach preserves the boot's material and ensures consistent protection.

The "Pre-Season" Rule of Thumb

Applying a waterproofing treatment during a stretch of warm, dry weather allows the product to cure properly without being immediately challenged by moisture. This makes late summer an excellent, predictable time to prepare for the coming fall and winter.

The "Anytime" Reality

However, unpredictable weather means there is no truly "bad" time to add a layer of protection. If your boots are starting to absorb water, it's time for a reapplication, regardless of the season. Consistent care every few months is key.

Optimizing the Application Process

The effectiveness of any waterproofing treatment depends entirely on the preparation and application technique. Following the correct steps ensures the product performs as intended.

Start with a Clean Surface

Begin by thoroughly cleaning your boots with a stiff brush and a damp rag. Dirt, mud, and grit create a barrier that prevents the waterproofing agent from penetrating the boot's material, leading to a weak and uneven seal.

The Damp Leather Advantage

Here is a critical, often-overlooked step: for leather boots, it's best to apply waxes or conditioning sealants while the leather is clean and slightly damp. The residual moisture within the leather's fibers helps draw the treatment deeper into the material, creating a much more thorough and durable barrier.

A Step-by-Step Guide

- Clean: Remove all surface dirt and debris.

- Warm (Optional): Gently warm the leather with a hairdryer on a low setting. This opens up the pores of the leather, improving absorption. Do not overheat the boot.

- Apply: Use a clean rag to apply the sealant evenly across the entire boot, paying special attention to seams and welting, which are common failure points.

- Dry & Finish: Buff off any excess product and let the boots dry naturally for at least 24 hours. For fabric or combination boots, finish with a dedicated waterproof spray.

Understanding Your Boot's Construction

Not all waterproofing is created equal. The type of boot you have dictates the type of care it needs.

Boots with Waterproof Membranes

Many modern work boots feature an internal waterproof, breathable membrane like Gore-Tex or eVent. For these boots, the external treatment you apply serves to maintain the Durable Water Repellent (DWR) finish on the outer material. This prevents the leather or fabric from getting waterlogged, which is crucial for allowing the internal membrane to breathe and release sweat.

Traditional Leather and Fabric Boots

For boots without a built-in waterproof liner, the wax, sealant, or spray you apply is the primary barrier against moisture. Regular and thorough application is absolutely essential for keeping your feet dry.

Common Pitfalls and Trade-offs

Waterproofing is a balancing act. Understanding the limitations helps you set realistic expectations for performance and longevity.

The Impact on Breathability

Heavy applications of wax-based products on full-grain leather boots can inhibit their natural breathability. While this maximizes water resistance, it may lead to warmer, sweatier feet in mild conditions. This is a trade-off between external protection and internal comfort.

The Myth of a Permanent Solution

No waterproofing treatment is permanent. Abrasion from walking, exposure to dirt, and flexing of the material will eventually wear down the protective barrier. Regular inspection and reapplication are necessary to maintain performance.

Applying This to Your Work Environment

Your profession and the conditions you face should guide your maintenance strategy.

- If your primary focus is routine care for all-leather boots: Perform a deep clean and apply a conditioning sealant during the late summer and touch it up as needed throughout the wet season.

- If your primary focus is maintaining performance on boots with a Gore-Tex liner: Regularly clean the exterior and reapply a DWR spray to prevent the outer material from "wetting out" and to ensure breathability.

- If your primary focus is protecting your boots in a demanding, wet environment (e.g., plumbing, construction): Inspect your boots weekly for wear and reapply treatment to high-stress areas like seams and flex points more frequently.

Ultimately, treating your work boots is an investment in your own comfort, health, and safety on the job.

Summary Table:

| Key Consideration | Ideal Timing / Action |

|---|---|

| Proactive Season | Late summer / Early fall, before the wet season |

| Critical Condition | Boots are clean and leather is slightly damp |

| For Membranes (e.g., Gore-Tex) | Focus on maintaining the DWR coating on the exterior |

| For Heavy-Use Environments | Inspect and reapply to high-stress areas more frequently |

Keep Your Workforce Safe and Dry with 3515's Durable Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of waterproof and safety work boots for distributors, brand owners, and bulk clients. Our production capabilities ensure your teams have reliable, comfortable, and long-lasting footwear for any demanding environment.

Ready to equip your workforce with superior footwear? Contact our team today to discuss your specific needs and explore our extensive catalog.

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What is the difference between regular boots and waterproof boots in terms of design? The Critical Feature Explained

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- What are the key features for warehouse and logistics work boots? Ensure Safety and All-Day Comfort

- How should you dry the boots after cleaning? The Definitive Guide to Preserving Your Footwear

- How do designers address breathability in TPU work boots? Balancing Durability with Comfort

- What is the significance of waterproof and chemical resistance in firefighting boots? Essential Protection for Firefighters

- What are Western work boots? The Ultimate Guide to Safety and Style

- How do IoT sensor environments contribute to the lifecycle management of industrial boots? Smart Data-Driven Safety