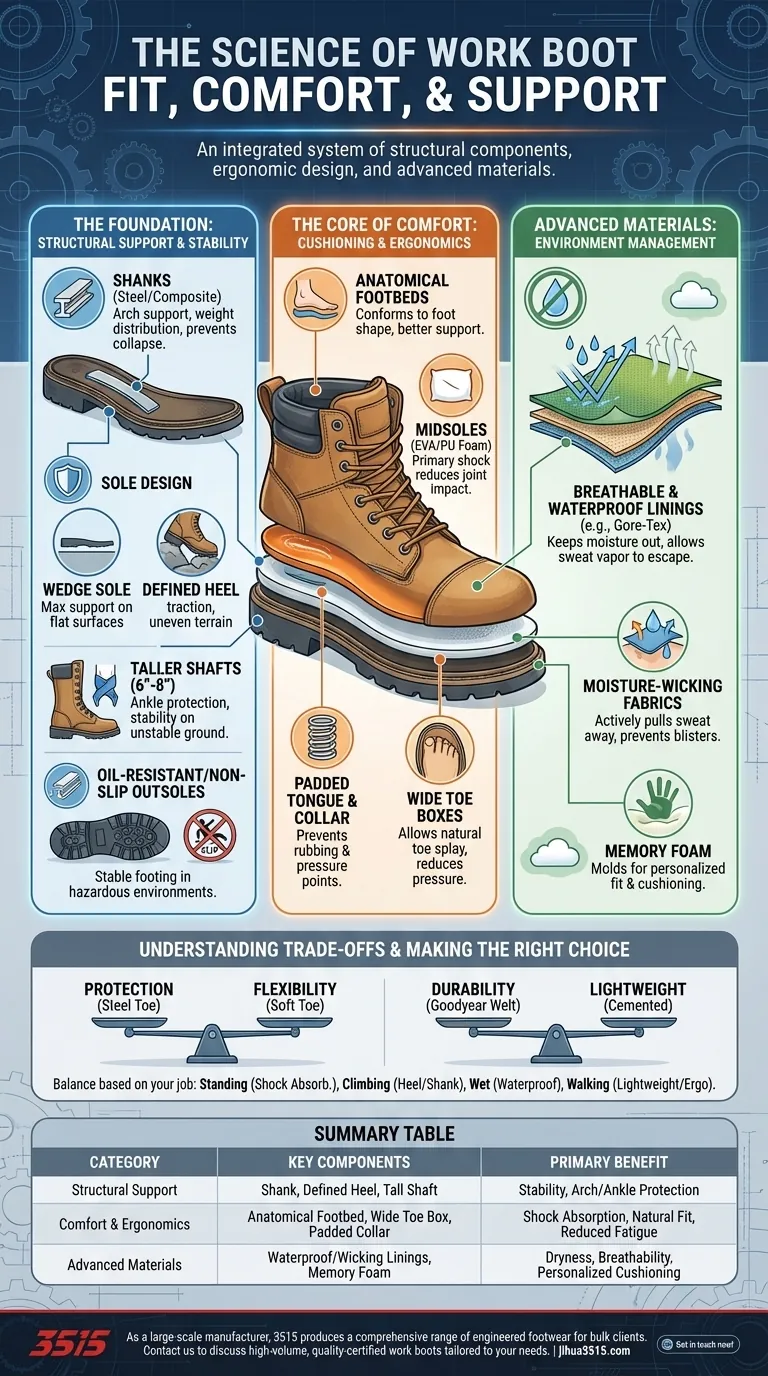

At its core, superior fit, comfort, and support in work boots come from a combination of three key elements: foundational structural components like shanks and soles, ergonomic design features such as anatomical footbeds and wide toe boxes, and advanced materials that provide cushioning and manage moisture. These features work together as a system to distribute weight, reduce fatigue, and protect your feet.

The most comfortable and supportive work boot is not just a protective shell; it's an integrated system where the boot's structure, shape, and materials are engineered to work with the natural mechanics of your foot.

The Foundation: Structural Support and Stability

Before considering cushioning, you must evaluate the boot's underlying structure. This is what provides long-term support and prevents the muscular strain that leads to fatigue and pain.

Shanks for Proper Weight Distribution

A shank is a rigid piece of material, often steel or composite, placed between the insole and outsole.

It provides critical support to your arch, preventing the boot from collapsing under your weight, especially when climbing ladders or standing on narrow surfaces.

Sole Design: Wedge vs. Defined Heel

Wedge soles offer a large, flat surface area that provides maximum support and cushioning for those standing all day on hard, flat surfaces like concrete.

Defined heel soles offer superior traction and stability on uneven terrain, making them ideal for outdoor work, climbing, and navigating debris.

Taller Shafts for Ankle Protection

Boots with a taller design (e.g., 6-inch or 8-inch) provide crucial ankle support, reducing the risk of twists and sprains on unstable ground.

This feature also protects the lower leg from abrasions and impacts.

Oil-Resistant and Non-Slip Outsoles

The outsole is your direct point of contact with the ground. An oil-resistant and non-slip design is a critical safety feature that ensures stable footing in hazardous environments, reducing the risk of falls.

The Core of Comfort: Cushioning and Ergonomics

Once the structural foundation is solid, comfort is determined by how well the boot is shaped to your foot and how effectively it absorbs impact.

Anatomical Footbeds and Insoles

Modern work boots increasingly use anatomical footbeds that conform to the natural shape of the human foot, providing better arch support and stability than a simple flat insole.

Many quality boots feature removable insoles, allowing you to use custom orthotics for personalized support.

Midsoles for Shock Absorption

The midsole is the primary layer for shock absorption. Materials like EVA foam or air-infused polyurethane cushion every step, drastically reducing the impact transferred to your joints and lower back.

Padded Tongues and Collars

A padded tongue and collar prevent uncomfortable rubbing and pressure points around the ankle and the top of the foot, especially when laces are tied securely.

Wide Toe Boxes

An ergonomic toe box, often square or anatomically shaped, allows your toes to splay naturally. This reduces pressure, prevents cramping, and improves balance over long shifts.

Advanced Materials for a Better Environment

The materials used inside the boot play a major role in all-day comfort by managing heat, moisture, and fit.

Breathable and Waterproof Linings

Linings made with materials like Gore-Tex create a barrier that is both waterproof and breathable.

This technology keeps external moisture out while allowing sweat vapor to escape, keeping your feet dry and comfortable in various conditions.

Moisture-Wicking Fabrics

High-performance boots often use moisture-wicking linings that actively pull sweat away from your skin. This is essential for preventing blisters and mitigating the effects of perspiration.

Memory Foam for a Personalized Fit

Some boots incorporate memory foam in the insoles or ankle area. This material molds to the unique contours of your foot, providing personalized cushioning and reducing pressure points.

Understanding the Trade-offs

Choosing the right boot always involves balancing competing priorities. Being aware of these trade-offs is key to making an informed decision.

Protection vs. Flexibility

Safety features like steel toes offer maximum impact protection but can add weight and reduce flexibility compared to lighter composite toes or soft-toe designs.

Durability vs. Weight

Traditional construction methods like a Goodyear welt create an extremely durable and resoleable boot, but this often results in a heavier and less flexible boot than one with a cemented or direct-attached sole.

Waterproofing vs. Breathability

Even the most advanced waterproof membranes have a limit. In very hot conditions, a fully waterproof boot will almost always be less breathable than a non-waterproof alternative made with highly breathable fabrics.

Making the Right Choice for Your Job

Your specific work environment and daily tasks should dictate which features you prioritize.

- If your primary focus is standing on concrete all day: Prioritize boots with excellent shock absorption from a thick midsole and a supportive wedge sole.

- If your primary focus is climbing or navigating uneven terrain: Choose a boot with a defined heel for traction, a rigid shank for arch support, and a taller shaft for ankle stability.

- If your primary focus is working in wet or changing weather: Invest in a reliable waterproof and breathable lining like Gore-Tex to keep your feet dry and comfortable.

- If your primary focus is minimizing fatigue from constant walking: Look for lightweight designs, flexible outsoles, and ergonomic features like an anatomical footbed and a wide toe box.

Choosing the right boot is a direct investment in your daily performance, safety, and long-term health.

Summary Table:

| Feature Category | Key Components | Primary Benefit |

|---|---|---|

| Structural Support | Shank, Defined Heel, Tall Shaft | Stability, Arch Support, Ankle Protection |

| Comfort & Ergonomics | Anatomical Footbed, Wide Toe Box, Padded Collar | Shock Absorption, Reduced Fatigue, Natural Fit |

| Advanced Materials | Waterproof Linings, Moisture-Wicking Fabrics, Memory Foam | Dryness, Breathability, Personalized Cushioning |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots engineered with the precise features outlined above—ensuring your customers receive durable, comfortable, and supportive work footwear tailored to their specific job demands. Contact us today to discuss your requirements and leverage our expertise in delivering high-volume, quality-certified work boots that enhance safety and performance. Get in touch now!

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How do pull on work boots accommodate wider feet or higher insteps? Discover the Ultimate Comfort Fit

- How have synthetic materials influenced the design of Western boots? Boost Performance & Safety

- How does high-performance professional footwear serve as an ergonomic intervention to reduce physiological fatigue in high-intensity work environments? Boost Performance & Safety!

- What are the key advantages of neoprene work boots? Superior Protection for Cold & Wet Conditions

- How should lace-up boots be properly worn? Master the Fit for All-Day Comfort and Support

- How do composite toe work boots perform in different weather conditions? Stay Comfortable in Extreme Heat and Cold

- What should you look for in puncture-resistant work boots to ensure compliance? Verify the ASTM F2413 'PR' Label

- What makes the Mortar boots suitable for corrosive environments? Unmatched Chemical Resistance & Durability