Regardless of the material used, all protective toe caps in safety footwear must meet the same performance requirements for impact and compression resistance. The governing standard in the United States is ASTM F2413, which ensures a consistent level of protection whether the toe is made of steel, aluminum, or a composite material. This means the choice between materials is about factors like weight and thermal conductivity, not the fundamental level of safety.

The core principle is simple: OSHA mandates that employers ensure a safe workplace, which includes protection against foot injuries. ASTM International is the organization that sets the specific, testable performance standards that this footwear must meet, with ASTM F2413 being the definitive specification for protective toe caps.

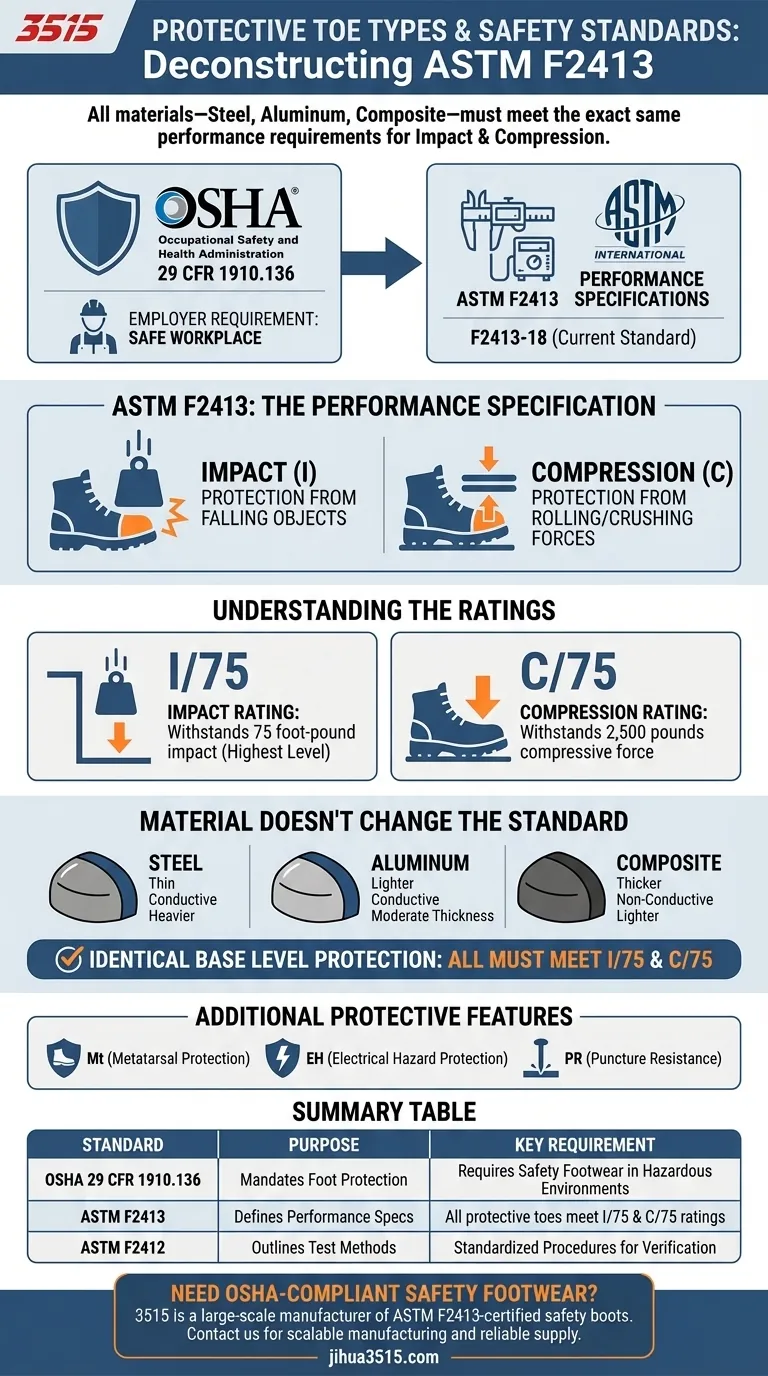

Deconstructing the Core Safety Standards

To truly understand protective footwear, it's essential to see how the regulatory bodies and standards organizations work together. One sets the "why," and the other defines the "how."

The Role of OSHA

The Occupational Safety and Health Administration (OSHA) is a government agency that sets and enforces workplace safety regulations.

OSHA standard 29 CFR 1910.136 mandates that employers require protective footwear in work environments where there is a danger of foot injuries. However, OSHA does not write the detailed technical specifications for the footwear itself.

The Role of ASTM International

ASTM International (formerly the American Society for Testing and Materials) is a global organization that develops and publishes technical standards for a vast range of products and materials.

ASTM provides the specific benchmarks that safety footwear must meet to be considered compliant. The two key standards are ASTM F2412 (Standard Test Methods for Foot Protection) and ASTM F2413 (Standard Specification for Performance Requirements for Protective Footwear).

ASTM F2413: The Performance Specification

This is the most critical standard for end-users. It establishes the minimum performance requirements for safety footwear.

For protective toe caps, the standard centers on two specific hazards: Impact (I) and Compression (C). Every protective toe, regardless of material, must meet these minimums.

Understanding the Ratings on Your Boot

The ASTM F2413 standard uses a clear labeling system, which is typically found on a tag sewn inside the footwear. Understanding this label is key to verifying protection.

What "I/75" Means

The Impact rating (I) measures the toe cap's ability to protect the foot from falling objects.

The "75" indicates the highest level of protection, signifying that the toe cap can withstand a 75 foot-pound impact. This is the standard for most heavy-duty industrial and construction work.

What "C/75" Means

The Compression rating (C) measures the toe cap's ability to protect the foot from rolling or crushing forces.

The "75" rating here indicates the toe cap can withstand 2,500 pounds of compressive force before it begins to crack or deform significantly.

Beyond the Toe Cap

The ASTM F2413 standard also defines codes for other protective features that a boot might have, including:

- Mt (Metatarsal Protection)

- EH (Electrical Hazard Protection)

- PR (Puncture Resistance)

Common Pitfalls and Clarifications

Trusting the standards is crucial, but it requires understanding their scope and limitations. Misinterpretations can lead to a false sense of security.

Material Doesn't Change the Standard

It's a common misconception that one material is inherently "safer" than another. A composite toe must pass the exact same I/75 and C/75 tests that a steel toe must pass.

The trade-offs are in other areas. Steel is often thinner but conducts temperature, while composite is thicker and non-conductive but may be lighter. The base level of impact and compression protection, however, is identical.

Standard Versions Matter

Standards are periodically updated. The references mention older versions like F2413-05, while the current standard is F2413-18.

Always look for compliance with the most recent version of the standard to ensure the footwear has been tested against the latest safety protocols.

Compliance vs. Suitability

A boot that is fully ASTM F2413 compliant is not automatically suitable for every job. Compliance with the toe cap standard is just the starting point.

A workplace risk assessment must be performed to identify all potential hazards. A job requiring protection from corrosive materials or slippery surfaces requires a boot designed for those specific threats, in addition to having a compliant safety toe.

How to Ensure Proper Compliance

When selecting or verifying protective footwear, focus on the specific hazards of your environment and match them to the boot's certified ratings.

- If your primary focus is general worksite safety: Look for footwear explicitly labeled as compliant with ASTM F2413-18, ensuring it has both I/75 and C/75 ratings.

- If you work near live electrical circuits: Verify the boot also has an "EH" rating in addition to the standard protective toe ratings.

- If your environment has risks from heavy rolling objects or falling tools: Consider footwear with additional Metatarsal (Mt) guards for protection over the top of the foot.

- If you work where sharp objects like nails are on the ground: Actively seek out a Puncture Resistant ("PR") rating to protect the sole of your foot.

Ultimately, understanding these standards empowers you to look beyond marketing and confirm that your footwear provides a certified, non-negotiable level of protection.

Summary Table:

| Standard | Purpose | Key Requirement |

|---|---|---|

| OSHA 29 CFR 1910.136 | Mandates employer-provided foot protection | Requires safety footwear in hazardous environments |

| ASTM F2413 | Defines performance specifications | All protective toes must meet I/75 (impact) and C/75 (compression) ratings |

| ASTM F2412 | Outlines test methods | Provides standardized procedures for verifying footwear safety |

Need OSHA-compliant safety footwear for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-certified safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear with steel, aluminum, and composite toes that meet the same rigorous impact and compression standards.

We ensure your workers get consistent, certified protection while you benefit from our scalable manufacturing, competitive pricing, and reliable supply chain.

Contact us today to discuss your protective footwear requirements and receive a customized quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What should women consider when choosing safety footwear for their work environment? Get the Right Fit and Protection

- What are the core considerations for choosing reinforced safety shoes? Structural Integrity vs. Standard Training Shoes

- What are the key material performance requirements for safety footwear? Guide to ASTM F2413 & OSHA Compliance

- How do ankle braces function as an enhancement to protective footwear? Maximize Stability & Safety During Landings

- What does the infographic mentioned in the article cover? Prevent Workplace Foot Injuries with the Right Safety Footwear

- What are OSHA's requirements for preventing slips, trips, and falls? Build a Safer Workplace with Proactive Controls

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What is the function of pressure insoles in safety shoes? High-Precision Gait Analysis and Load Assessment