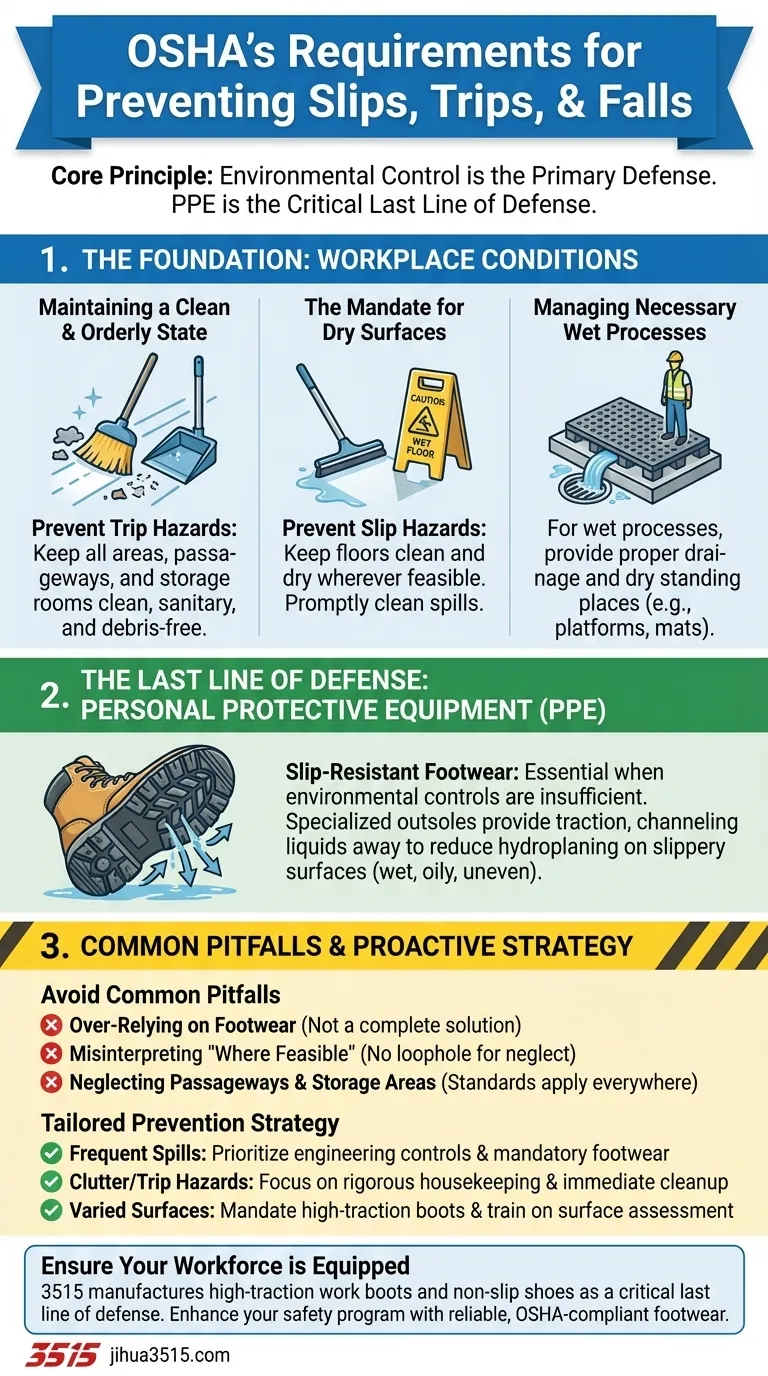

At its core, OSHA’s requirements for preventing slips, trips, and falls prioritize environmental control. The agency mandates that employers maintain all walking and working surfaces in a clean, orderly, and dry condition. For areas where wet processes are necessary, employers must ensure proper drainage and provide dry standing places, such as platforms or mats.

The fundamental principle behind OSHA’s rules is that a safe environment is the primary defense against falls. Personal protective equipment, such as non-slip footwear, is a critical but secondary measure used to protect employees when environmental hazards cannot be completely eliminated.

The Foundation: Workplace Condition Requirements

The most effective way to prevent falls is to address the root causes within the workplace itself. OSHA's standards are built on this proactive approach.

Maintaining a Clean and Orderly State

OSHA requires all workplaces, passageways, and storage rooms to be kept in a clean and sanitary condition. This is the first step in preventing trip hazards, which are often caused by clutter, misplaced materials, or debris.

An orderly environment ensures that pathways are clear and potential obstacles are removed before they can cause an incident.

The Mandate for Dry Surfaces

The primary rule for preventing slip hazards is to keep floors clean and dry wherever feasible. This addresses common risks like spills, weather-related moisture, and leaks.

Employers are responsible for implementing procedures for prompt cleanup and ensuring walking surfaces are maintained properly.

Managing Necessary Wet Processes

OSHA recognizes that some industrial processes inherently involve liquids. In these specific situations, where keeping a floor completely dry is not possible, the requirement shifts.

Employers must provide solutions like proper drainage to prevent the accumulation of liquids. Additionally, they must supply false floors, platforms, or mats to give employees a safe, dry place to stand.

The Last Line of Defense: Personal Protective Equipment (PPE)

When environmental controls alone cannot guarantee safety, slip-resistant footwear becomes essential. It serves as the final protective layer between the employee and a potentially hazardous surface.

How Slip-Resistant Shoes Work

Properly designed work boots and non-slip shoes feature specialized treaded outsoles. These treads are engineered to provide extra grip and traction on the ground.

The outsole pattern is designed to channel liquids like water, oil, or mud out from under the shoe. This action maintains direct contact between the sole and the floor, significantly reducing the risk of hydroplaning and slipping.

Providing Traction on Dangerous Surfaces

The benefit of this technology is most apparent on the slippery, wet, oily, or uneven surfaces common in construction, workshops, hospitals, and industrial facilities.

By providing a reliable grip, this footwear helps employees stay upright and prevents serious injuries such as sprains, cuts, and broken bones.

Common Pitfalls to Avoid

Achieving true compliance requires avoiding common misinterpretations of the regulations. Relying on a single solution is rarely sufficient.

Over-Relying on Footwear

A frequent mistake is to view slip-resistant shoes as a complete solution. PPE is always the last line of defense.

If a floor is covered in oil or significant debris, even the best footwear can fail. The primary focus must always be on correcting the environmental hazard first.

Misinterpreting "Where Feasible"

The phrase "where feasible" is not a loophole to avoid cleaning spills. It applies to work processes that are inherently wet.

If a floor can be kept dry, it must be. If it cannot, the employer is then obligated to install the secondary controls, like mats and drainage, that OSHA requires.

Neglecting Passageways and Storage Areas

Safety standards must be applied consistently across the entire facility. Slips and trips are just as likely to occur in a cluttered stockroom or a wet hallway as they are in the primary work area.

OSHA’s rules for clean, orderly, and dry conditions apply to all walking surfaces an employee might use.

A Proactive Strategy for Fall Prevention

Your prevention strategy should be tailored to the specific risks present in your environment. Use the following guidelines to focus your efforts.

- If your workplace has frequent spills or wet processes (e.g., kitchens, manufacturing): Prioritize engineering controls like enhanced drainage and permanent anti-slip flooring first, supplemented by a mandatory slip-resistant footwear policy.

- If your primary risk is clutter and trip hazards (e.g., warehouses, retail stockrooms): Focus on rigorous housekeeping protocols, clear aisle markings, and a culture of immediate cleanup for any debris.

- If your environment has varied or unpredictable surfaces (e.g., construction, field service): Mandate certified, high-traction work boots and train employees to visually inspect and assess surface stability.

A safe workplace is not a matter of chance; it is the result of consistent, proactive environmental control.

Summary Table:

| Requirement Category | Key OSHA Mandate |

|---|---|

| Environmental Control | Keep all walking surfaces clean, orderly, and dry. |

| Wet Process Management | Provide drainage and dry standing places (e.g., mats, platforms). |

| Personal Protective Equipment (PPE) | Use slip-resistant footwear when hazards cannot be fully eliminated. |

| Common Pitfalls | Avoid over-relying on footwear and neglecting passageways/storage areas. |

Ensure your workforce is equipped with the right safety footwear to meet OSHA's requirements.

As a large-scale manufacturer, 3515 produces a comprehensive range of high-traction work boots and non-slip shoes for distributors, brand owners, and bulk clients. Our footwear is engineered with specialized outsoles to channel liquids and provide superior grip on slippery surfaces, serving as a critical last line of defense for your employees.

Contact us today to discuss your bulk order needs and enhance your workplace safety program with reliable, OSHA-compliant footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- What is the SB classification for safety shoes? A Guide to Basic Footwear Protection

- What are the advantages of safety shoes as carriers for inertial navigation? Boost Precision for Your High-Tech Boots

- What is the primary protective role of S2 level safety shoes? Essential Protection for Industrial Environments

- Why is professional industrial-grade safety footwear a suitable carrier for diabetic rehabilitation insoles?

- What type of work shoes benefit individuals with high arches? Find Support for Long-Hour Comfort

- How does the production process contribute to the lightness of composite toe caps? Achieve Superior Comfort & Safety

- What are the advantages of using professional safety shoes with arch support for sewing operators? Boost Productivity

- What are the disadvantages of EVA in safety shoes? Understand the trade-offs for your workforce.