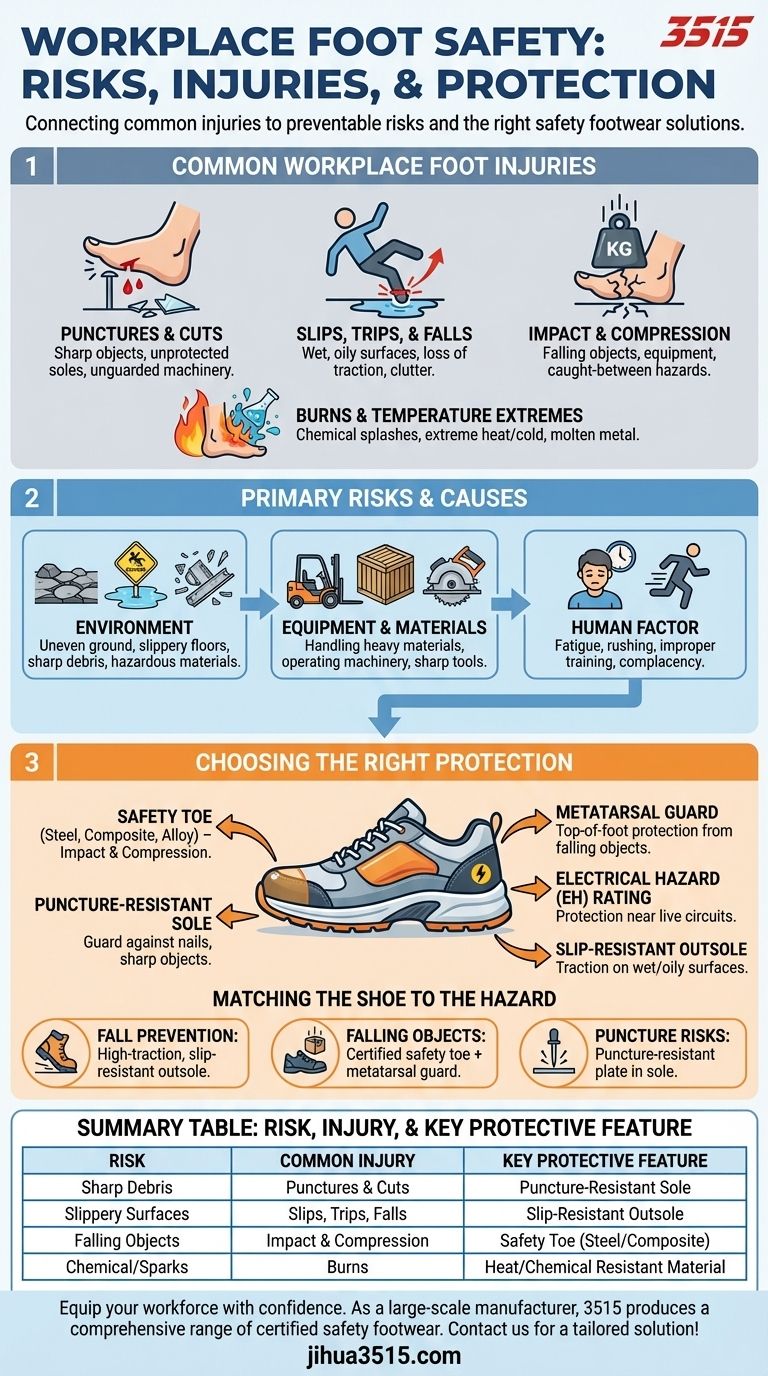

To be direct, the infographic covers the most common workplace foot injuries, the primary risks that cause them, and guidance on selecting the proper safety footwear for protection. This information is designed to help both workers and safety managers make informed decisions to prevent incidents before they happen.

The core purpose of the infographic is not just to list injuries, but to connect them directly to preventable risks and tangible solutions—namely, the correct selection and use of safety shoes.

Understanding the Landscape of Foot Injuries

The infographic's first goal is to establish the scope of the problem. It highlights the most frequent and severe types of injuries that occur in professional environments.

Punctures and Cuts

Punctures are a primary concern, often caused by stepping on sharp objects like nails, scrap metal, or glass. The sole of the foot is especially vulnerable.

Cuts and lacerations can happen from any angle, typically involving machinery with unguarded moving parts or dropped tools and materials.

Slips, Trips, and Falls

These are among the most common workplace accidents overall, and they frequently result in foot and ankle injuries like sprains, fractures, and strains.

The cause is often a loss of traction on wet, oily, or cluttered surfaces.

Impact and Compression

Heavy objects falling onto the foot can cause severe crushing injuries, leading to broken bones and significant tissue damage. This is a major risk in construction, warehousing, and manufacturing.

Compression injuries can also occur when a foot is caught between objects or run over by equipment like forklifts or carts.

Burns and Temperature Extremes

Feet are also at risk from chemical splashes, molten metal, or contact with extreme heat or cold. These scenarios can cause severe burns or frostbite if the footwear is not properly insulated.

Connecting Injuries to Common Risks

The infographic effectively draws a line from the injury to the cause. Understanding the specific risks present in your work environment is the critical next step in prevention.

The Role of the Environment

The work environment itself is the source of many risks. This includes uneven ground, slippery floors, and the presence of sharp debris or hazardous chemicals.

The Risk from Equipment and Materials

Handling heavy materials, operating machinery, and working with sharp tools are all direct risk factors. The infographic emphasizes how these elements directly threaten foot safety.

The Human Factor

Finally, factors like fatigue and rushing can increase the likelihood of an accident. While not a physical hazard, human behavior is an undeniable part of the risk equation.

Choosing the Right Protection

The most actionable part of the infographic is its guidance on selecting appropriate safety footwear. It moves beyond a simple recommendation and explains the why behind the choices.

Matching the Shoe to the Hazard

The central principle is that no single safety shoe is right for every job. A shoe designed to protect against punctures may not offer adequate slip resistance.

Therefore, the first step is always a thorough risk assessment of the specific tasks and environment.

Key Features to Look For

The infographic likely details critical safety features, such as:

- Safety Toes (Steel, Composite, or Alloy): Essential for protection against impact and compression.

- Puncture-Resistant Soles: A must-have for environments with sharp debris.

- Slip-Resistant Outsoles: Crucial for preventing slips on wet or oily surfaces.

- Metatarsal Guards: Provide protection to the top of the foot from falling objects.

- Electrical Hazard (EH) Rating: For those working near live electrical circuits.

Making the Right Choice for Your Goal

- If your primary focus is preventing falls: Prioritize safety shoes with a high-traction, slip-resistant outsole designed for the specific surfaces in your workplace.

- If your primary focus is protection from falling objects: Ensure your footwear has a certified safety toe and, for higher-risk areas, a metatarsal guard.

- If your primary focus is avoiding punctures: Select a shoe with a puncture-resistant plate built into the sole to guard against nails and other sharp objects.

By understanding the connection between risks, injuries, and protective features, you can effectively reduce the likelihood of foot-related incidents.

Summary Table:

| Risk | Common Injury | Key Protective Feature |

|---|---|---|

| Sharp Debris | Punctures & Cuts | Puncture-Resistant Sole |

| Slippery Surfaces | Slips, Trips, Falls | Slip-Resistant Outsole |

| Falling Objects | Impact & Compression | Safety Toe (Steel/Composite) |

| Chemical/Sparks | Burns | Heat/Chemical Resistant Material |

Equip your workforce with confidence. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots designed to mitigate the specific risks outlined in this article. Let us help you protect your team—contact us today for a tailored solution!

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- Why is industrial-grade foot protection essential for CME maintenance? Shield Workers from Crushing & Shock Hazards

- How does shock absorption in work shoes benefit workers? Protect Joints and Reduce Fatigue

- Why is it essential for professional safety shoes to feature arch support and anti-slip functions? Boost Safety Now

- What are the key considerations when choosing safety boots? Match Hazards to Features for Maximum Protection

- What are composite toe boots? A Guide to Lightweight, Non-Metallic Safety Footwear

- What is the function of the shank in a safety boot? The Key to Arch Support & Stability

- What key features enhance the functionality of firefighter boots? Built for Extreme Safety & Performance

- What role do foot-mounted reference sensors play in gait detection? Master High-Precision Training for Safety Footwear