To choose the right work boots, you must prioritize three key areas: safety features tailored to your specific trade's hazards, the quality and durability of the materials, and the all-day comfort and support provided by the boot's construction. These elements work together to ensure you are protected, productive, and free from pain after long hours on your feet.

The most effective work boot is not the one with the most features, but the one with the right features for your specific job site hazards. Prioritizing your trade's unique risks over generic safety labels is the single most important factor in your decision.

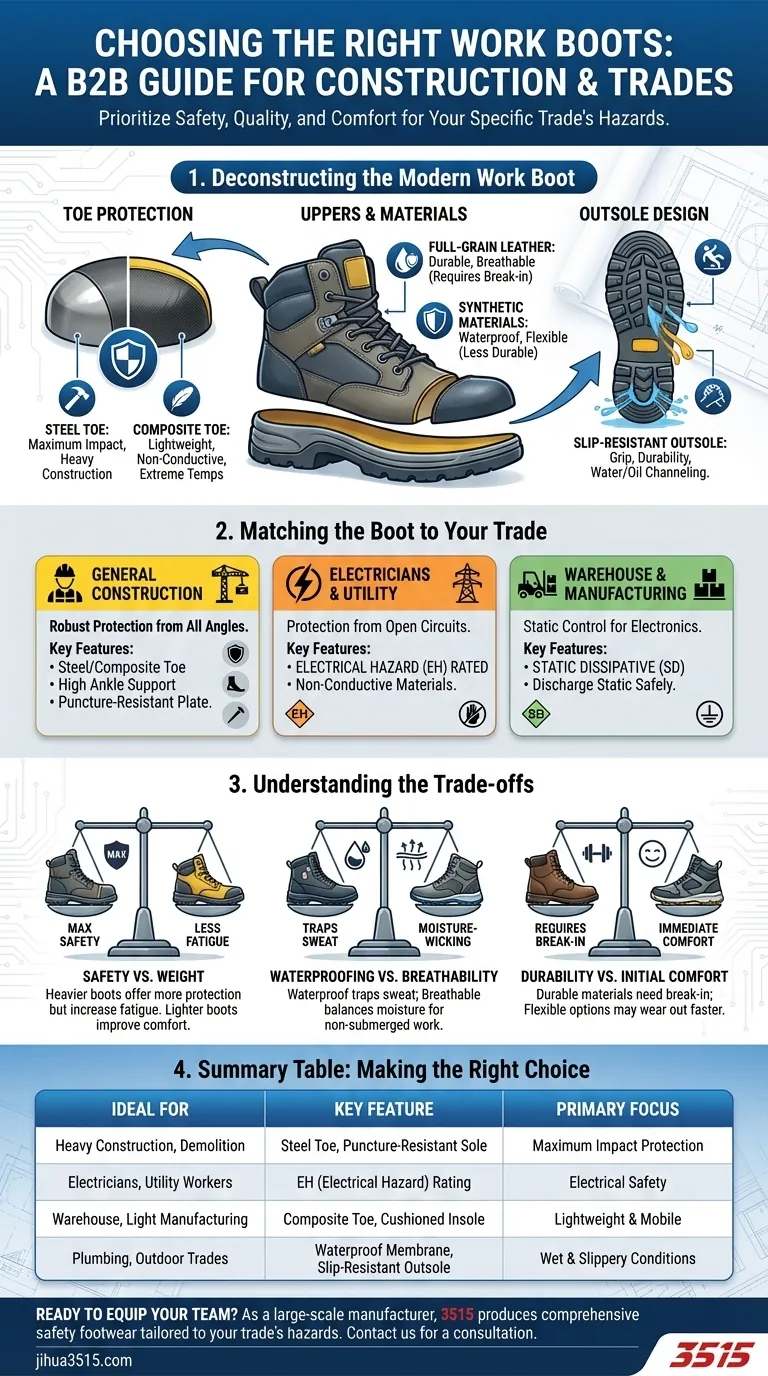

Deconstructing the Modern Work Boot

Understanding the components of a work boot is the first step in making an informed choice. Each part serves a distinct purpose, and the materials used will dictate its performance, durability, and comfort.

Toe Protection: Steel vs. Composite

The most recognized safety feature is the protective toe cap. This is your primary defense against impact and compression from falling objects or heavy machinery.

Steel toes are the traditional standard, offering maximum protection against heavy impacts. They are often required on industrial and heavy construction sites.

Composite toes, made from materials like carbon fiber, Kevlar, or plastic, are a lighter alternative. They don't conduct heat, cold, or electricity, making them ideal for workers in extreme temperatures or those who pass through metal detectors frequently.

Outsole Design: Grip and Resistance

The outsole is where the boot meets the ground, and its design is critical for preventing slips, trips, and falls—one of the most common job site accidents.

Look for boots with a clearly defined slip-resistant tread pattern designed to channel away water and oil. The material of the sole, typically rubber or TPU, also contributes significantly to its grip and durability.

Uppers and Materials: Durability Meets Comfort

The upper part of the boot protects your foot from the elements and workplace hazards. High-quality materials are essential for longevity and comfort.

Full-grain leather is a premium choice known for its exceptional durability, breathability, and water resistance. However, it often requires a break-in period.

Synthetic materials can offer excellent waterproofing and are often lighter and more flexible right out of the box, though they may not be as durable as high-quality leather.

Matching the Boot to Your Trade

Different jobs expose you to different risks. A generic "safety boot" is rarely the optimal choice. You must align the boot's specific safety ratings with the known hazards of your profession.

For General Construction

Workers on construction sites need robust protection from every angle. Key features include a steel or composite safety toe, high ankle support to prevent twists on uneven ground, and a puncture-resistant plate in the sole to guard against nails.

For Electricians and Utility Workers

The primary concern for electricians is protection from open circuits. Electrical Hazard (EH) rated footwear is essential. These boots are constructed with non-conductive materials to provide a secondary source of protection from electrocution.

For Warehouse and Manufacturing

In environments where static electricity can damage sensitive electronic components, Static Dissipative (SD) boots are required. These boots are designed to safely discharge static electricity from your body to the ground.

Understanding the Trade-offs

Choosing the perfect work boot always involves balancing competing priorities. Being aware of these trade-offs will help you select a boot that aligns with your most critical needs.

Safety vs. Weight

Heavier boots with steel toes and thick rubber soles often provide the highest level of protection. However, that extra weight can lead to significant fatigue over a long shift. Lighter composite-toe boots can drastically improve comfort and reduce strain.

Waterproofing vs. Breathability

A fully waterproof boot is excellent for wet conditions but can trap sweat, leading to discomfort and blisters. A water-resistant boot with a breathable, moisture-wicking lining often provides a better balance for those who aren't constantly submerged in water.

Durability vs. Initial Comfort

The toughest, most durable boots are typically made from thick, full-grain leather that requires a break-in period. More flexible, synthetic boots might feel great immediately but may not withstand the same level of abuse over time.

Making the Right Choice for Your Work

Ultimately, your choice should be a direct response to your daily work environment and physical needs.

- If your primary focus is maximum impact protection (heavy construction, demolition): A steel-toe boot with a puncture-resistant sole is the non-negotiable standard.

- If your primary focus is electrical safety (electrician, utility worker): An EH-rated boot is an essential piece of personal protective equipment.

- If your primary focus is all-day comfort and mobility (light manufacturing, warehouse work): A lightweight composite-toe boot with a cushioned insole will reduce fatigue and improve efficiency.

- If your primary focus is working in wet conditions (plumbing, outdoor trades): Prioritize boots with a reliable waterproof membrane and a high-traction, slip-resistant outsole.

Investing in footwear designed specifically for the challenges of your trade is a direct investment in your own safety and well-being.

Summary Table:

| Key Consideration | Key Feature | Ideal For |

|---|---|---|

| Maximum Impact Protection | Steel Toe, Puncture-Resistant Sole | Heavy Construction, Demolition |

| Electrical Safety | EH (Electrical Hazard) Rating | Electricians, Utility Workers |

| Lightweight & Mobile | Composite Toe, Cushioned Insole | Warehouse, Light Manufacturing |

| Wet & Slippery Conditions | Waterproof Membrane, Slip-Resistant Outsole | Plumbing, Outdoor Trades |

Ready to Equip Your Team with the Right Work Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots and shoes, tailored to the specific hazards of your trade.

We ensure your workforce is protected, productive, and comfortable with durable, safety-compliant footwear.

Contact 3515 today for a consultation and discover how our manufacturing expertise can meet your specific needs.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium KPU Injection Athletic Style Safety Shoes

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- What are the core features of quality engineer boots? Built for Durability, Protection & Style

- What type of leather is used in wildland firefighter boots? Discover the NFPA-Certified Material

- What additional protection do metatarsal boots provide? Achieve Full Instep Safety from Impact and Compression

- What are the sizing and fit considerations for women's work boots? A Safety & Comfort Guide

- What are the key features of engineer boots? Discover Their Unmatched Durability & Iconic Style

- How should boot material choice be prioritized? Find the Perfect Work Boot for Your Job

- What safety boots are recommended for the oil and gas industry? Essential Features for Hazardous Sites

- What are PVC work boots made of? A Complete Guide to Their Durable, Waterproof Construction