1. Let's get to the core of the matter: The initial question is straightforward: what type of leather? But, as a professional, I know the real question is why this specific leather is chosen. It's about understanding the properties, the rationale behind the selection, and the role of other crucial materials.

2. Diving Deeper into the Details:

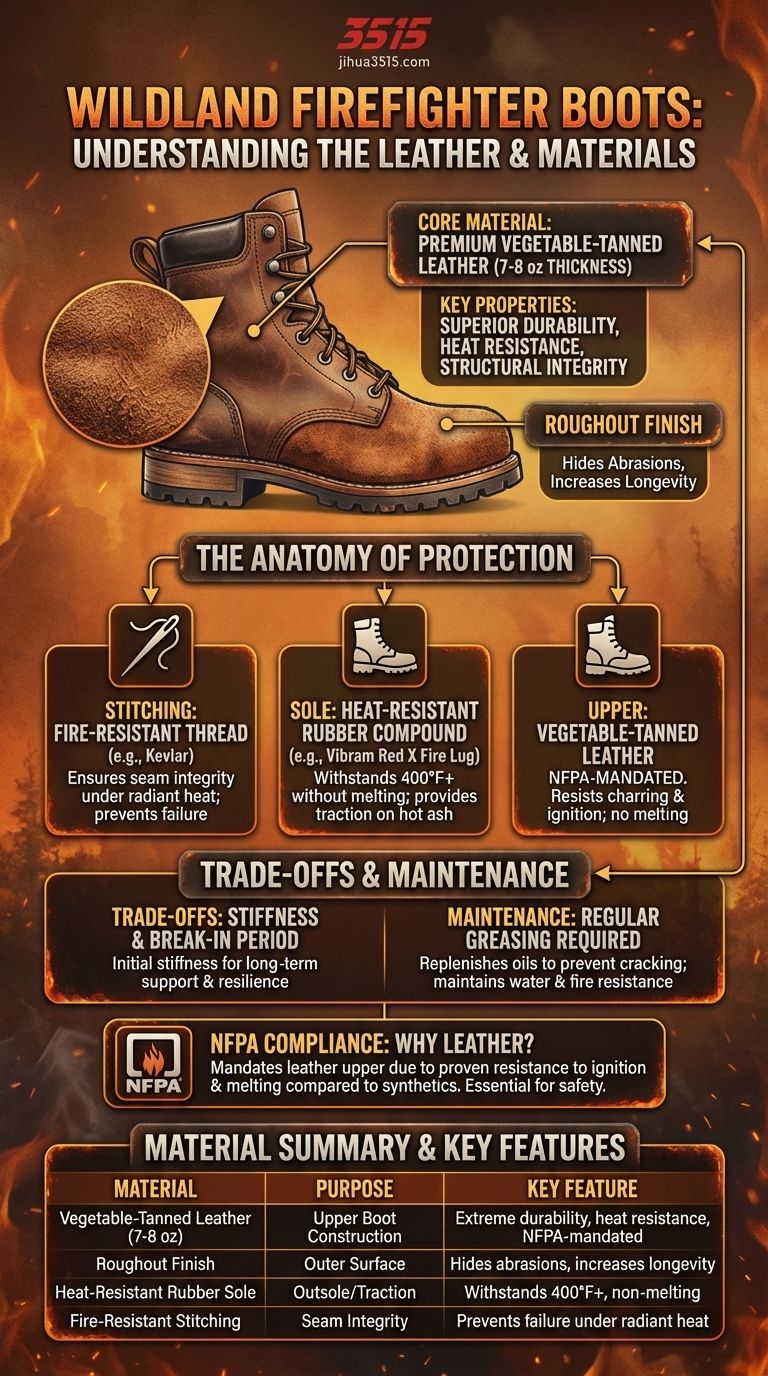

- The Leather: We're dealing with "premium vegetable-tanned leather," typically around 7 to 8 oz in thickness. The references are pretty clear on that. It's chosen for its durability and resistance to wear. The "roughout" finish is also preferred; it's the flesh side of the hide, which is like suede. It hides damage better and increases abrasion resistance, a key advantage for this type of demanding work. We also see references to "high-quality leather" in other contexts, but the specific mention of vegetable-tanning is key for wildland boots.

- Beyond the Leather: It's not just leather, though. We're talking about a system. Other materials include nylon, synthetic fibers, rubber, Kevlar, and moisture-wicking fabrics in different parts of the boot. We also see the outsole (the part that touches the ground) is made of a heat-resistant rubber compound (like Vibram Red X Fire Lug) and often has a lug design for traction. The threads used in stitching are also fire-resistant. The National Fire Protection Agency (NFPA) explicitly specifies that these boots must be constructed from leather. The NFPA specifies that the leather is chosen due to its durability and ignition resistance when greased.

- The Rationale: This whole system is designed for heat resistance and durability. The heavy-duty veg-tan leather offers strength and abrasion resistance, while the heat-resistant sole provides protection from high temperatures. The other materials play their part in support, moisture control, and overall comfort.

3. Putting It All Together:

- The most valuable answer is that wildland fire boots require heavy-duty, vegetable-tanned leather, often in a roughout finish. It's typically 7-8 oz in thickness. This isn't just a material choice; it's about the unique combination of durability, heat resistance, and structural integrity. Safety standards like the NFPA back up this choice.

- While the leather upper is crucial, these boots are more than just leather. Fire-resistant threads, the heat-resistant outsole, moisture-wicking liners, and supportive elements all play their part.

- We need to understand the trade-offs. The stiff vegetable-tanned leather requires a break-in period, but this is a trade-off for its durability and fire resistance. The leather needs regular maintenance and greasing to keep its protective qualities.

- Why not synthetics? The NFPA standard mandates leather for the upper because of its proven resistance to ignition and melting.

4. Making the Right Choice:

- For those prioritizing safety certification, a full-leather upper and a heat-resistant sole are essential.

- If long-term durability is the goal, invest in veg-tan roughout leather and commit to a good break-in and maintenance routine.

- If immediate comfort and traction are key, pay close attention to the insole design and outsole lug pattern.

Understanding these materials empowers us to choose the right gear and stay safe in the field. At its core, a wildland firefighter boot is built from heavy-duty, vegetable-tanned leather. This specific type of leather, typically 7 to 8 ounces in thickness, is chosen for its superior durability and structural integrity under extreme stress. Most high-quality boots will feature a "roughout" finish, where the flesh side of the hide faces outward to better resist and hide abrasions.

The selection of leather for wildland boots is not a matter of style but a critical engineering choice. Vegetable-tanned roughout leather is mandated by safety standards because it provides an unparalleled combination of heat resistance, durability, and physical support essential for operating in hazardous environments.

The Anatomy of a Wildland Boot

While the leather upper is the most visible component, a certified wildland boot is a system of specialized materials working in concert. Each part is chosen to solve a specific problem encountered on the fireline.

The Leather Upper: Your First Line of Defense

Vegetable-tanned leather is fundamentally different from the softer leathers used in casual footwear. It is tanned using natural tannins from plant matter, a process that results in a stiffer, denser, and more durable material.

This inherent rigidity is precisely why it's used. It provides excellent support on unstable ground and is highly resistant to wear and tear. The roughout texture further enhances its longevity by hiding the inevitable scuffs and scrapes of fieldwork.

The Sole: A Heat-Resistant Foundation

The outsole is your only connection to the ground, which can be super-heated or slick. These boots feature a deep lug sole made from a specialized, heat-resistant rubber compound.

A prime example is the Vibram Red X Fire Lug outsole, which is engineered to withstand temperatures over 400°F without melting or degrading. This ensures you maintain traction and protection even when walking on hot ash or embers.

The Stitching: Holding It All Together

The thread used to stitch the boot together is just as critical as the leather itself. Standard threads would quickly fail when exposed to high heat.

Wildland boots use fire-resistant threads, often made from materials like Kevlar, to ensure the boot's structural integrity is not compromised by sparks or radiant heat.

The Interior: Managing Moisture and Impact

While the exterior is built for toughness, the interior focuses on stability and managing moisture. Many boots incorporate moisture-wicking liners made from nylon or polyester to help keep feet dry.

Additionally, features like reinforced heel counters provide crucial ankle support, reducing the risk of injury on steep and uneven terrain.

Understanding the Trade-offs

No material choice is without its compromises. Understanding these limitations is key to selecting and maintaining your equipment properly.

The Break-In Period

The primary trade-off for the durability of vegetable-tanned leather is its initial stiffness. Unlike more pliable leathers, these boots require a significant break-in period to conform to your foot. This is a necessary sacrifice for achieving long-term support and resilience.

The Necessity of Maintenance

Leather is a natural material that requires care. It must be regularly cleaned and treated with boot grease or conditioner. This process replenishes the oils in the leather, keeping it from drying out, cracking, and losing its water and fire-resistant properties.

The NFPA Standard: Why Leather is Mandated

The National Fire Protection Agency (NFPA) sets the standards for wildland firefighting gear. The NFPA specifies that the boot upper must be constructed from leather. This is because, unlike many synthetic materials that can melt and fuse to the skin when exposed to flame, leather tends to char and resist ignition, providing a critical layer of protection.

Making the Right Choice for Your Goal

Selecting the right boot means aligning its features with the demands of your job.

- If your primary focus is meeting safety certification: Ensure the boot is explicitly NFPA-compliant, which guarantees a full-leather upper, heat-resistant sole, and fire-resistant stitching.

- If your primary focus is long-term durability: Prioritize a boot made from thick, vegetable-tanned roughout leather and commit to a proper maintenance schedule with quality boot grease.

- If your primary focus is traction and stability: Look for a boot with a proven, deep-lug outsole like the Vibram Fire Lug and a reinforced heel for robust ankle support.

Ultimately, understanding the materials in your boots empowers you to trust your gear when it matters most.

Summary Table:

| Material | Purpose | Key Feature |

|---|---|---|

| Vegetable-Tanned Leather (7-8 oz) | Upper Boot Construction | Extreme durability, heat resistance, NFPA-mandated |

| Roughout Finish | Outer Surface | Hides abrasions, increases longevity |

| Heat-Resistant Rubber Sole (e.g., Vibram) | Outsole/Traction | Withstands 400°F+ temperatures, non-melting |

| Fire-Resistant Stitching (e.g., Kevlar) | Seam Integrity | Prevents failure under radiant heat |

Need NFPA-compliant wildland fire boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of professional boots, including rugged wildland firefighter models built with premium vegetable-tanned leather and heat-resistant components.

We ensure durability, compliance, and bulk-order efficiency. Contact our experts today for custom quotes and catalog access.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How should one choose between cowboy boots and Western work boots? A Guide to Function and Style

- Are insulated work boots waterproof? Uncover the Crucial Difference for Your Safety

- What materials are recommended for durable metal details in boots? Solid Brass vs. Stainless Steel

- What does the 'EH' in ASTM F2413-18 M/I/C EH PR MT stand for? Decode Safety Boot Labels for Maximum Protection

- What does impact resistance in ASTM standards entail? Achieve Maximum Toe Protection with I/75 Rating

- What should you look for in the construction quality of work boots? Ensure Durability, Safety & Repairability

- What are the common materials used for work boot soles? A Guide to Durability, Comfort & Safety

- What does the ASTM F2413-18 certification ensure for work boots? A Guide to Decoding Safety Ratings