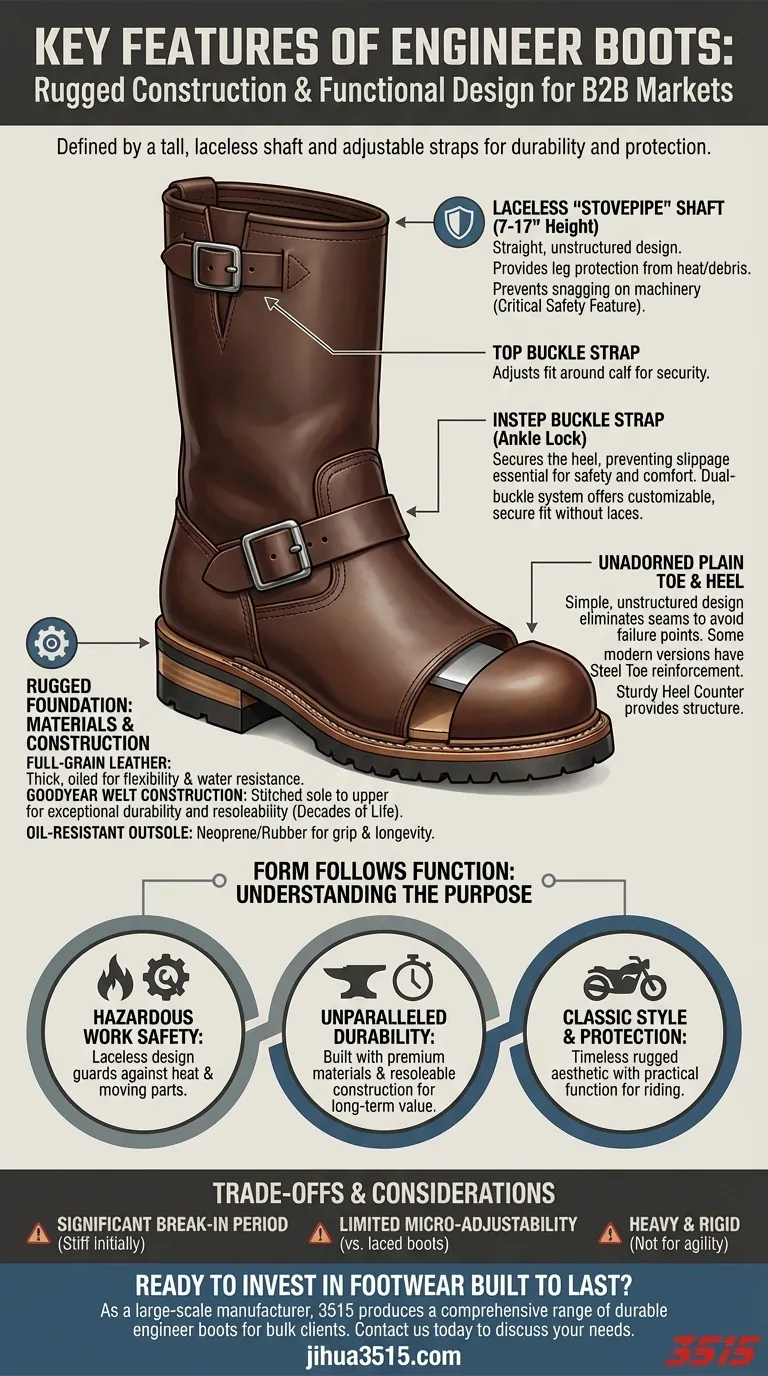

At its core, an engineer boot is a laceless work boot defined by its rugged construction and adjustable straps. Originally designed for workers in hazardous environments like railroads, its key features include a tall, unstructured "stovepipe" shaft, a plain toe, and distinctive buckle straps at both the instep and the top of the boot. These elements combine to create a boot prized for its durability, protection, and iconic style.

The design of the engineer boot is a direct reflection of its purpose. Every key feature—from the absence of laces to the heavy-duty leather—was engineered to provide maximum protection and a secure fit for individuals working around dangerous machinery and hot engines.

Deconstructing the Engineer Boot: Form Follows Function

To truly understand engineer boots, you must look at how each component serves a specific, practical purpose. The design isn't accidental; it's a masterclass in functional workwear that has remained relevant for nearly a century.

The Laceless "Stovepipe" Shaft

The most recognizable feature is the tall, laceless shaft, often called a "stovepipe" due to its straight, unstructured shape. Shaft height typically ranges from 7 to 17 inches.

This design provides crucial protection for the lower leg against heat, debris, and abrasion. Most importantly, the lack of laces prevents the boot from snagging on moving parts, a critical safety feature for railroad engineers and motorcyclists.

The Dual-Buckle System

In place of laces, engineer boots use a system of two adjustable leather straps with metal buckles. One is positioned over the instep to secure the ankle, while the other is located at the top of the shaft to adjust the fit around the calf.

This system allows for a customizable yet highly secure fit. The instep strap is vital for locking the heel in place to prevent slippage, which is essential for both comfort and safety.

The Rugged Foundation: Materials and Construction

Engineer boots are built to endure. They are almost always crafted from thick, full-grain leather, which is often oiled for added flexibility and water resistance.

The highest quality versions use a Goodyear welt or stitch-down construction. This method of stitching the sole to the upper makes the boot exceptionally durable and, critically, resoleable. This extends the life of the boot from years to decades. The outsoles are typically made of oil-resistant neoprene or thick rubber for grip and longevity.

The Unadorned Toe and Heel

The boot typically features a plain, rounded toe. This simple, unstructured design enhances durability by eliminating seams that could fail under stress. Some modern variations include a reinforced steel toe for added protection in work environments.

The heel counter is a separate, sturdy piece of leather that provides structure and support to the back of the boot.

Understanding the Trade-offs

While iconic and durable, the unique design of engineer boots comes with specific considerations that may not be suitable for everyone.

The Break-in Period

The thick leather and robust construction mean these boots require a significant break-in period. They can be stiff and uncomfortable out of the box and must be worn consistently to allow the leather to soften and mold to your foot.

Fit and Adjustability

While the buckles offer some customization, they do not provide the same micro-adjustments as a fully laced boot. Achieving the perfect initial fit is crucial, as you cannot tighten or loosen specific areas along the foot's length.

Weight and Flexibility

These are heavy, substantial boots. They are designed for protection and support, not for long-distance walking, running, or hiking. Their inherent rigidity can make them feel cumbersome for activities requiring agility.

Making the Right Choice for Your Goal

Selecting an engineer boot depends entirely on what you value most.

- If your primary focus is motorcycle safety: The laceless design, tall protective shaft, and heavy-duty leather make it an excellent choice for guarding against engine heat and road abrasion.

- If your primary focus is long-term durability: Seek out boots with a Goodyear welt construction and full-grain leather, as this ensures they can be resoled and maintained for decades.

- If your primary focus is classic style: The boot's rugged aesthetic is timeless, but be prepared for the break-in period and the boot's substantial weight.

Ultimately, choosing an engineer boot is an investment in a piece of functional history built for unparalleled durability.

Summary Table:

| Feature | Purpose | Benefit |

|---|---|---|

| Laceless Stovepipe Shaft | Protection from heat/debris; prevents snagging | Essential safety for hazardous work & motorcycling |

| Dual-Buckle System | Adjustable fit at instep and calf | Secure, customizable fit without laces |

| Full-Grain Leather & Goodyear Welt | Maximum durability and weather resistance | Long-lasting, resoleable boot built for decades |

| Plain Toe & Rugged Sole | Enhanced durability and oil-resistant grip | Simple, robust design for demanding environments |

Ready to invest in footwear built to last? As a large-scale manufacturer, 3515 produces a comprehensive range of durable engineer boots and other footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring you receive high-quality, reliable products. Contact us today to discuss your needs and discover how we can bring durable, iconic style to your customers.

Visual Guide

Related Products

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What is the historical significance of cowboy boots? From Essential Workwear to Cultural Icon

- What additional safety features might work boots have? Essential Protection for Your Job Site

- What are the common foot issues workers face due to uncomfortable work boots? Prevent Pain & Deformities

- What does the 'EH' in ASTM F2413-18 M/I/C EH PR MT stand for? Decode Safety Boot Labels for Maximum Protection

- Why is it important to replace safety boots over time? Avoid Hidden Hazards and Ensure Protection

- What are the disadvantages of pull on work boots? The Critical Fit & Safety Trade-Offs

- How should wildfire boots be maintained for optimal performance? A Guide to Longevity and Safety

- Why is proper fit crucial for fire boot protection? The Key to Safety and Performance