At its core, a metatarsal boot extends protection beyond the toe cap to shield the five long, fragile bones on the top of your foot. While a standard safety boot protects your toes from being crushed, a metatarsal boot adds a crucial guard against impact and compression injuries across the entire instep, a vulnerability often overlooked.

The essential difference is moving from partial to comprehensive foot protection. Metatarsal boots are designed for environments where the threat isn't just to the toes, but to the entire top of the foot from falling or rolling heavy objects.

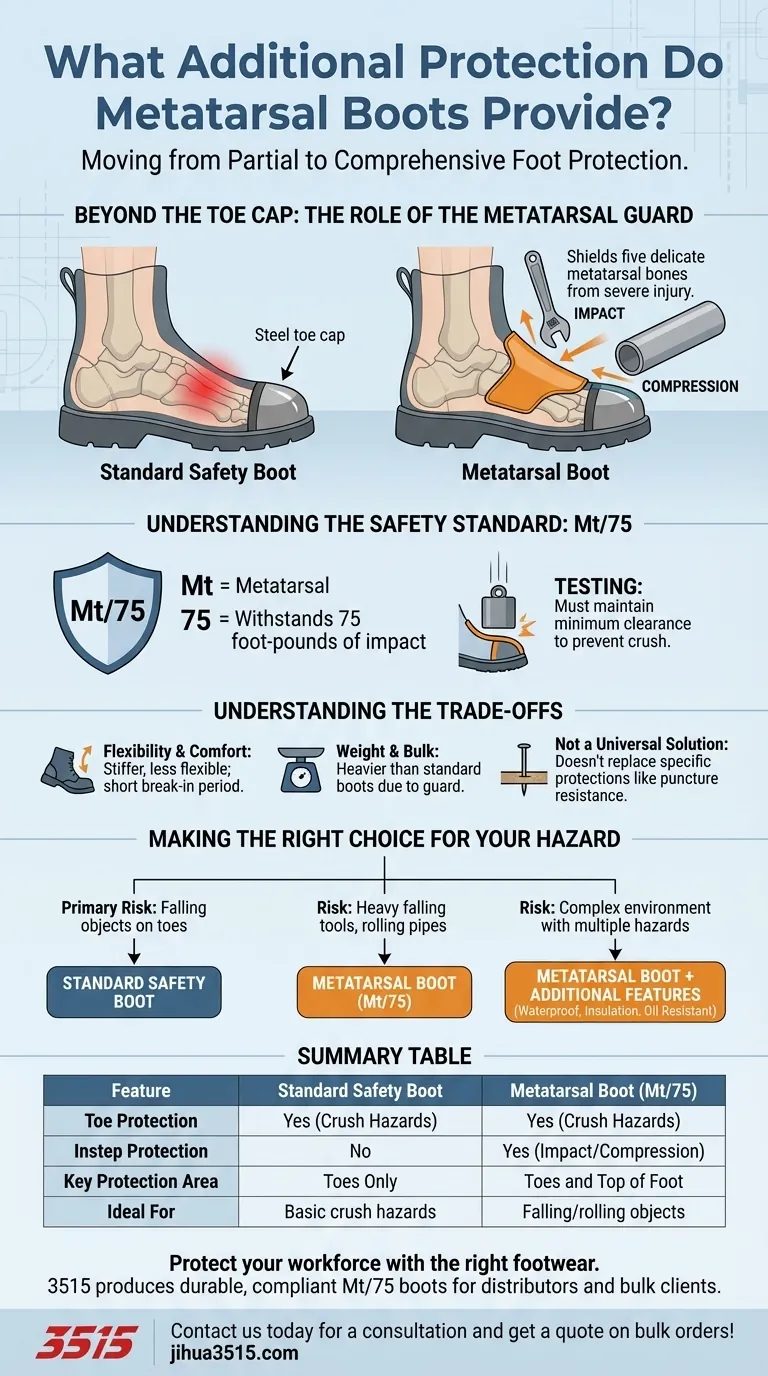

Beyond the Toe Cap: The Role of the Metatarsal Guard

Standard safety boots leave the top of your foot exposed. Metatarsal protection directly addresses this gap by covering the instep, which is highly susceptible to severe injury in many industrial settings.

Shielding the Metatarsal Bones

The five metatarsal bones connect your toes to the rest of your foot. They are relatively delicate and lack significant natural padding, making them vulnerable to fractures from direct impact.

Guarding Against Two Key Hazards

Metatarsal guards are specifically engineered to counter impact from falling objects (like tools or materials) and compression from heavy rolling objects (like pipes or cylinders). A standard toe cap offers no defense against these threats.

How the Protection Works

This protection is typically an external or internal shield that sits over the laces and instep. It's often made from high-impact materials and may be paired with a carbon strap and shock-absorbing pad to distribute the force of a blow.

Understanding the Safety Standard: Mt/75

When you see a boot rated as Mt/75, it signifies a specific level of metatarsal protection that has been rigorously tested.

Decoding the Rating

The "Mt" simply stands for metatarsal. The "75" indicates the boot is rated to withstand an impact of 75 foot-pounds (101.7 Joules).

What This Means in Practice

During testing, a weight is dropped onto the metatarsal guard. To pass, the boot must maintain a minimum clearance of 0.50 inches for men's boots and slightly less for women's, ensuring there is enough space to prevent the bones from being crushed.

Understanding the Trade-offs

While offering superior protection, metatarsal boots do come with practical considerations that differ from standard safety footwear.

Flexibility and Comfort

Metatarsal guards, particularly external ones, can make a boot feel stiffer and less flexible. This may require a short break-in period to get used to the feel.

Weight and Bulk

The additional protective components inevitably add some weight and bulk compared to a standard work boot. However, modern materials are continually reducing this difference.

Not a Universal Solution

It is important to match the boot to the hazard. Metatarsal protection is distinct from features like penetration resistance for sharp objects underfoot or enhanced ankle support found in specialized adventure boots.

Making the Right Choice for Your Hazard

Selecting the correct boot means moving beyond a simple "safety-toe" mindset and performing an honest risk assessment of your work environment.

- If your primary risk is from objects falling directly onto your toes: A standard steel or composite-toe boot meeting basic safety standards may be sufficient.

- If you work with heavy falling tools, rolling pipes, or raw materials: Metatarsal protection is a critical and often necessary safety upgrade.

- If you work in a complex environment with multiple hazards: Look for a boot that combines an Mt/75 rating with other key features like waterproofing, insulation, or oil resistance.

Ultimately, choosing the right footwear is about matching the level of protection directly to the specific dangers you face on the job.

Summary Table:

| Feature | Standard Safety Boot | Metatarsal Boot (Mt/75) |

|---|---|---|

| Toe Protection | Yes (Crush Hazards) | Yes (Crush Hazards) |

| Instep Protection | No | Yes (Impact/Compression) |

| Key Protection Area | Toes Only | Toes and Top of Foot |

| Ideal For | Basic crush hazards | Falling/rolling objects |

Protect your workforce with the right footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of metatarsal boots and safety footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure durable, compliant Mt/75 boots tailored to your specific industrial hazards. Contact us today for a consultation and get a quote on bulk orders!

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- Can you wear work boots every day? The Essential Guide to All-Day Comfort and Safety

- How should engineer boots be paired with denim? A Guide to the Perfect Fit and Cuff

- What is the significance of the approval label on NFPA-approved boots? Your Definitive Guide to Certified Safety

- Why are wildfire boots essential protective equipment? The Critical Role of Specialized Footwear

- What are the tips for maintaining warmth in winter biking boots? A System for Conquering Cold Feet

- What should be considered when purchasing composite toe work boots? Ensure Safety, Comfort & Job-Site Fit

- How do pull-on and lace-up boots differ in terms of convenience? The Ultimate Guide to Speed vs. Support

- What are electrical hazard (EH) rated work boots? Essential Secondary Protection for High-Risk Jobs