In the oil and gas industry, the best safety boots are not defined by a single brand, but by a specific set of non-negotiable protective features. The most critical requirements include steel toes for impact protection, slip- and oil-resistant outsoles for traction on hazardous surfaces, and durable, chemical-resistant materials to guard against corrosive substances.

Choosing the right boot for the oil and gas industry is a risk assessment. You must select a combination of protective features—from impact resistance to chemical protection—that directly counter the specific hazards you will face on-site.

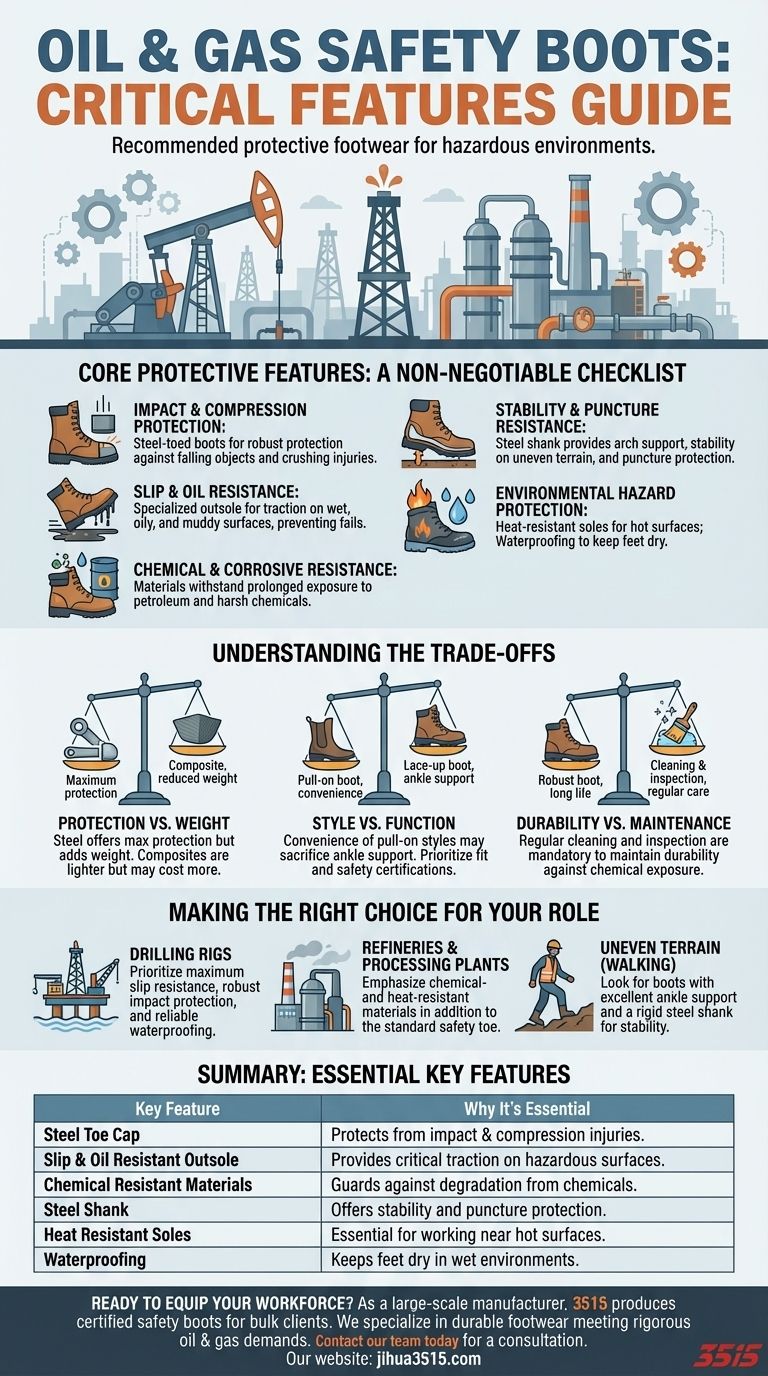

Core Protective Features: A Non-Negotiable Checklist

The environment in the oil and gas sector presents multiple, simultaneous risks. Your footwear is the primary line of defense against many of them, and it must be equipped accordingly.

Impact and Compression Protection

The most fundamental feature is a reinforced safety toe. Steel-toed boots are the traditional standard, providing robust protection against falling objects and crushing injuries from heavy equipment.

Slip and Oil Resistance

Work surfaces are frequently contaminated with water, oil, and drilling muds. A slip-resistant outsole specifically designed for these conditions is absolutely essential to maintain traction and prevent falls.

Chemical and Corrosive Resistance

Boots must be constructed from materials that can withstand prolonged exposure to petroleum products and other harsh chemicals without degrading. This ensures both the longevity of the boot and the safety of your feet.

Stability and Puncture Resistance

Many roles require long hours on uneven or debris-strewn terrain. A steel shank embedded in the midsole provides critical arch support and stability, reducing fatigue and protecting the underside of the foot from punctures.

Environmental Hazard Protection

Job sites can expose workers to extreme conditions. Heat-resistant soles are vital when working near hot equipment or surfaces, while waterproofing is necessary to keep feet dry in wet environments, preventing discomfort and potential health issues.

Understanding the Trade-offs

Selecting the perfect boot involves balancing maximum protection with practical, day-to-day usability. Understanding these compromises is key to making an informed decision.

Protection vs. Weight

Traditional steel components (toes, shanks) offer maximum protection but add significant weight, which can lead to fatigue over a long shift. Modern composite materials can offer similar protection levels at a reduced weight, but may come at a higher cost.

Style vs. Function

While certain styles like pull-on cowboy boots are popular for their convenience, they may offer less ankle support than a traditional lace-up work boot. The fit and the presence of safety certifications must always be prioritized over aesthetics.

Durability vs. Maintenance

Even the most robust boot will fail without proper care. Regular cleaning and inspection are mandatory. Exposure to chemicals can slowly break down materials, so you must consistently check for signs of cracking, separation, or wear.

Making the Right Choice for Your Role

Select your footwear based on the most common hazards of your specific job function.

- If your primary focus is working on drilling rigs: Prioritize maximum slip resistance, robust impact protection, and reliable waterproofing.

- If your primary focus is in a refinery or processing plant: Emphasize chemical- and heat-resistant materials in addition to the standard safety toe.

- If your primary focus involves extensive walking on uneven terrain: Look for boots with excellent ankle support and a rigid steel shank for stability.

Ultimately, the right boot is the one that allows you to perform your duties with confidence, knowing your foundation is secure.

Summary Table:

| Key Feature | Why It's Essential for Oil & Gas |

|---|---|

| Steel Toe Cap | Protects feet from impact and compression injuries from heavy equipment. |

| Slip & Oil Resistant Outsole | Provides critical traction on wet, oily, and muddy surfaces to prevent falls. |

| Chemical Resistant Materials | Guards against degradation from prolonged exposure to petroleum and harsh chemicals. |

| Steel Shank | Offers stability and arch support on uneven terrain and protects against punctures. |

| Heat Resistant Soles | Essential for working near hot equipment and surfaces. |

| Waterproofing | Keeps feet dry in wet environments, preventing discomfort and health issues. |

Ready to equip your workforce with the right safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots for distributors, brand owners, and bulk clients. We specialize in creating durable footwear that meets the rigorous demands of the oil and gas sector, combining essential protective features with long-lasting comfort.

Let us help you source the perfect boots for your specific on-site hazards. Contact our team today for a consultation and to discuss your requirements.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How have cowboy boots evolved over time? From functional gear to fashion icon

- What are some key features of recommended Western-style work boot models? Essential Safety & Comfort for Demanding Jobs

- What precautions should be taken when drying work boots? Avoid High Heat to Protect Your Investment

- What is the purpose of puncture-resistant work boots? Essential Foot Protection for Hazardous Job Sites

- What should be considered when choosing heavy duty work boots? The Ultimate Guide for Safety & Comfort

- What are the initial steps to take care of new work boots? Ensure Long-Term Comfort and Durability

- How do work boots protect against common construction hazards? A Guide to Essential Foot Safety

- What boots do firefighters wear? Choose the Right Gear for Maximum Safety & Performance