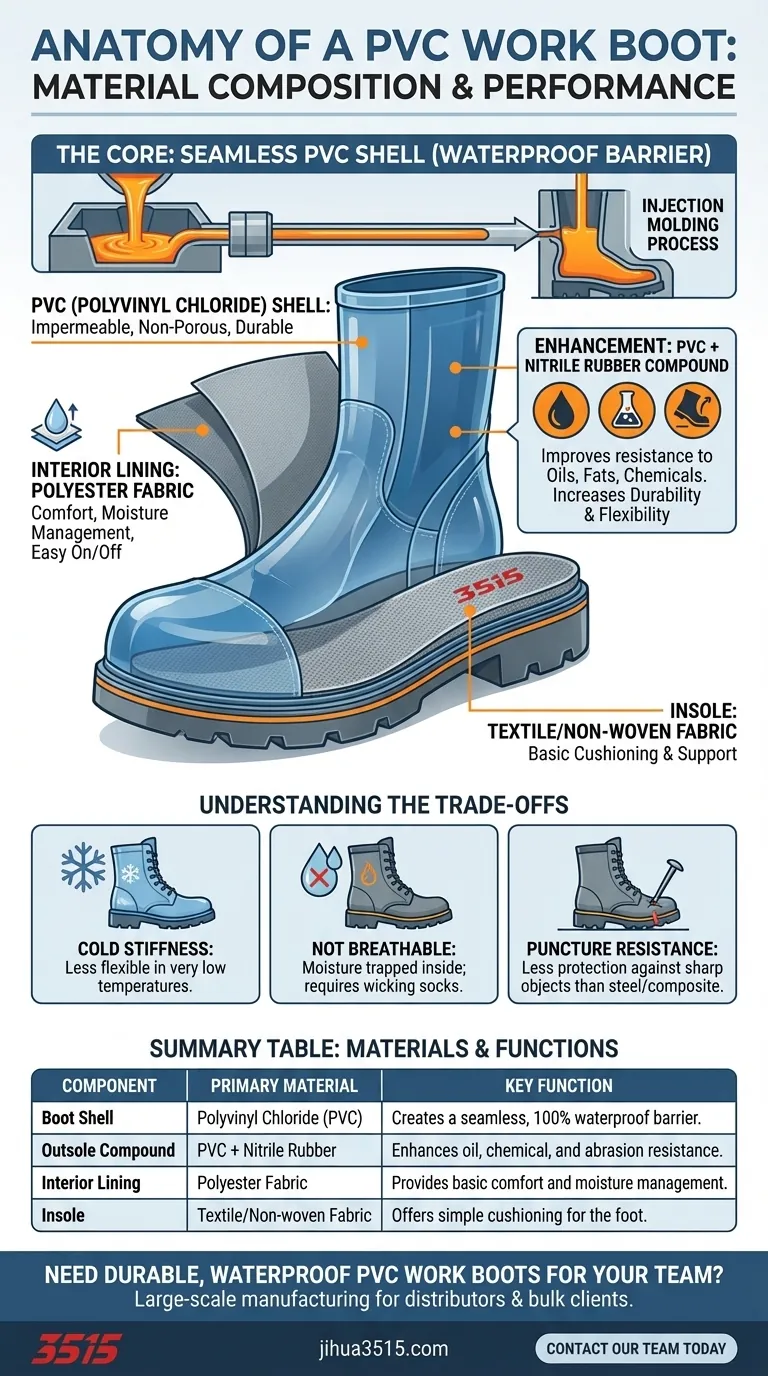

At their core, PVC work boots are constructed from a synthetic plastic polymer called polyvinyl chloride. This material is injection-molded to create a single, seamless, and completely waterproof shell. However, a modern work boot is more than just a plastic shell; it incorporates other materials to enhance durability, resistance, and comfort.

While polyvinyl chloride (PVC) forms the boot's main waterproof structure, a high-quality PVC work boot is actually a composite system. It typically blends PVC with nitrile rubber for superior durability and includes polyester linings and textile insoles for wearer comfort.

The Core Material: The PVC Shell

What is Polyvinyl Chloride?

Polyvinyl chloride, or PVC, is a widely used synthetic plastic. It is valued in industrial applications for its low cost, durability, and inherent resistance to water, acids, and alkalis.

How the Shell is Formed

The boot's main body is created through an injection molding process. Pellets of the PVC compound are heated until molten and then injected into a boot-shaped mold, creating a one-piece, seamless structure with no stitches or welds that could potentially leak.

The Primary Benefit: Impermeability

The single greatest advantage of PVC is that it is non-porous. This creates a completely waterproof barrier, ensuring feet remain dry in wet, muddy, or slushy conditions.

Key Components and Enhancements

The Role of Nitrile Rubber

Many PVC work boots are not 100% PVC. They are often made from a compound that includes a percentage of nitrile rubber, sometimes around 10%.

This addition significantly improves the boot's resistance to oils, fats, chemicals, and animal-based fluids, while also increasing its overall durability and flexibility.

The Interior Lining

The inside of the boot is typically lined with a synthetic fabric like polyester. This lining is not for structure but for comfort. It helps manage moisture from sweat and allows the foot to slide in and out of the boot more easily.

The Insole and Sole Construction

The insole, the part your foot rests on, is often a simple piece of textile material and non-woven fabric designed for basic cushioning.

The outsole is also made from the PVC/nitrile compound but may be formulated differently across layers to optimize for grip, shock absorption, and wear resistance.

Understanding the Trade-offs

Temperature and Flexibility

Standard PVC has a tendency to become stiff and less flexible in very cold temperatures. This can make walking more cumbersome and may increase the risk of the material cracking over time.

Breathability

The same impermeability that makes PVC boots waterproof also means they are not breathable. In warm conditions or during strenuous activity, sweat can build up inside the boot, as there is nowhere for the moisture vapor to escape.

Puncture Resistance

While durable against scuffs and chemicals, a PVC shell offers less protection against sharp punctures from nails or glass compared to heavy-duty leather or specialized composite boots.

Making the Right Choice for Your Goal

Understanding the material composition helps you match the boot to the job.

- If your primary focus is waterproofing and chemical resistance: PVC's seamless, non-porous construction makes it an excellent and highly cost-effective choice for agriculture, food processing, and general wet-environment work.

- If you work in extremely cold climates: You should specifically look for PVC boots rated for cold weather or consider natural rubber alternatives, which tend to remain more flexible.

- If your work involves long hours of strenuous activity: The lack of breathability is a key factor; pairing PVC boots with high-quality, moisture-wicking socks is essential for managing comfort.

By recognizing what PVC boots are made of, you can better leverage their strengths for the specific demands of your work environment.

Summary Table:

| Component | Primary Material | Key Function |

|---|---|---|

| Boot Shell | Polyvinyl Chloride (PVC) | Creates a seamless, 100% waterproof barrier. |

| Outsole Compound | PVC + Nitrile Rubber | Enhances oil, chemical, and abrasion resistance. |

| Interior Lining | Polyester Fabric | Provides basic comfort and moisture management. |

| Insole | Textile/Non-woven Fabric | Offers simple cushioning for the foot. |

Need durable, waterproof PVC work boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of PVC and rubber boots, tailored to meet the specific demands of industries like agriculture, food processing, and construction.

We can provide you with high-quality, cost-effective footwear solutions that ensure safety and comfort. Contact our team today to discuss your requirements and request a quote.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What factors should be considered when choosing farm boots? A Guide to Finding the Right Boot for Your Land

- What are heavy duty work boots designed for? Maximum Protection for Hazardous Work Environments

- What conditions are water-resistant boots suitable for? Optimal Comfort for Light Moisture

- Why is electrical hazard protection necessary in fire boots? A Critical Defense Against Electrocution

- How do the design and function of western boots differ from work boots? Choosing the Right Footwear for Your Environment

- Why is ankle support important in work boots? Essential for Safety and Stability on Any Job Site

- How do PU boots compare in weight? Achieve 40% Lighter Footwear for Less Fatigue

- How does the use of a 50th percentile male body model improve the ergonomic design of industrial work boots?