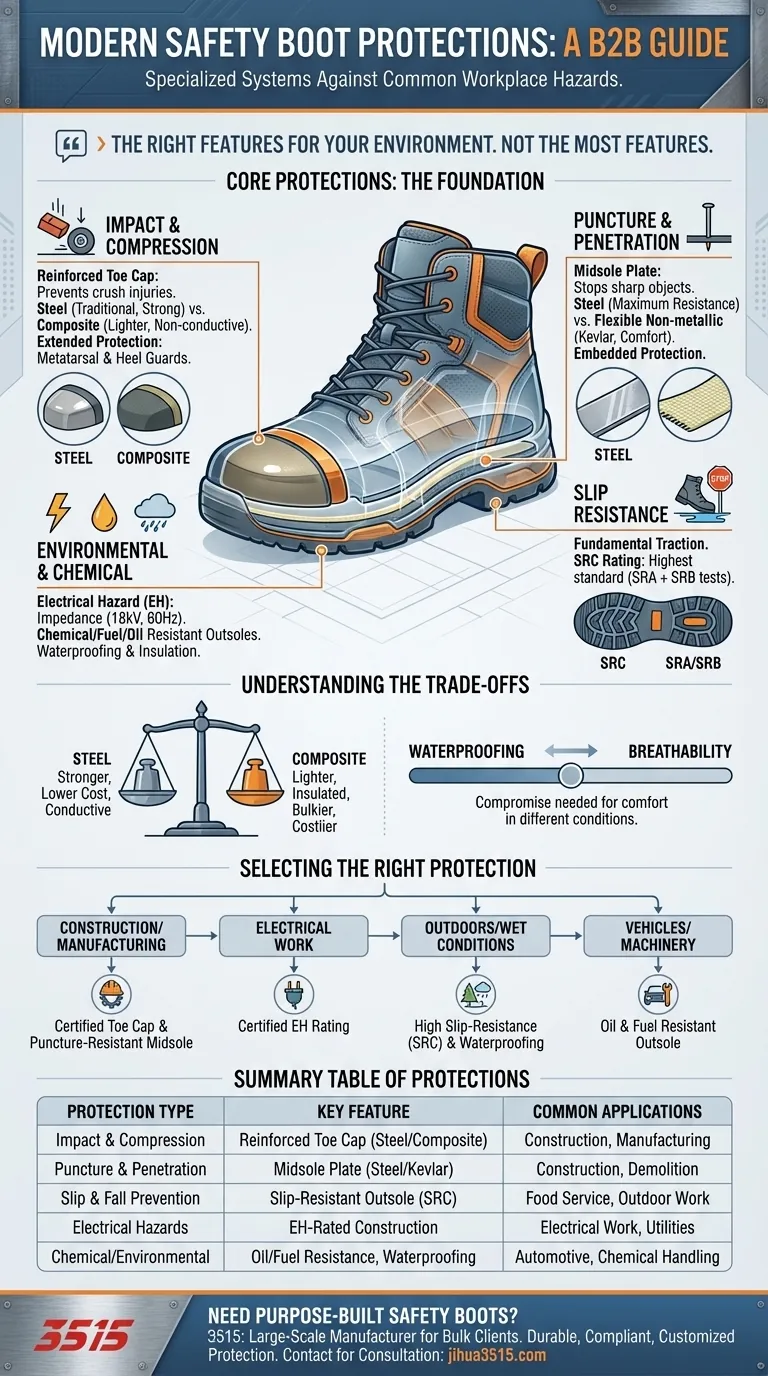

At their core, modern safety boots offer a specialized system of protection against common workplace hazards. The most critical features include reinforced safety toes for impact, penetration-resistant midsoles to guard against sharp objects, slip-resistant outsoles for traction, and options for guarding against electrical, chemical, and environmental dangers.

The most effective safety boot isn't the one with the most features; it's the one with the right features for your specific environment. Understanding the distinction between different types of protection is crucial for ensuring true safety on the job.

Protection from Physical Impact & Compression

The most recognized feature of a safety boot is its ability to protect your feet from being crushed or struck by heavy objects.

The Essential Toe Cap

A reinforced toe cap is the primary defense against falling debris, compression from rolling equipment, and other direct impacts. This feature is designed to prevent broken bones and severe crush injuries.

Steel vs. Composite Materials

Steel toe caps are the traditional standard, offering excellent resistance to impact and puncture. Composite toe caps (made from materials like Kevlar, carbon fiber, or plastic) are lighter, do not conduct electricity, and provide better insulation in extreme temperatures.

Beyond the Toe: Guards and Reinforcement

Some boots offer extended protection. A metatarsal guard sits on top of the boot to protect the delicate bones in the upper foot, while reinforced heel and ankle areas provide stability and defense against side impacts.

Shielding from Puncture and Penetration

Hazards on the ground are just as dangerous as those from above. Protection from below is a critical, non-negotiable feature in many work environments.

The Role of the Midsole Plate

A penetration-resistant plate is embedded in the midsole of the boot, directly under your foot. Its sole purpose is to stop sharp objects like nails, screws, or metal shards from piercing through the sole and injuring your foot.

Common Midsole Materials

Like toe caps, these plates are typically made of steel for maximum puncture resistance. Flexible, non-metallic options made from materials like Kevlar are also common, offering greater comfort and lighter weight without compromising safety.

Mitigating Environmental & Chemical Hazards

A modern safety boot must also function as a barrier between the worker and the specific environmental conditions of their job site.

Slip-Resistant Outsoles

Traction is a fundamental safety feature. Soles are often rated for their slip resistance on different surfaces, with SRC being the highest rating, indicating it has passed both tests on ceramic tiles with soap (SRA) and steel floors with glycerol (SRB).

Electrical Hazard (EH) Protection

Boots with an EH rating are designed to impede the flow of electricity. According to ASTM standards, they must be able to withstand 18,000 volts at 60 Hz for one minute in dry conditions with no significant current leakage, protecting workers from accidental contact with live electrical circuits.

Chemical, Fuel, and Oil Resistance

For automotive, industrial, or chemical handling jobs, the boot's outsole and upper materials must be resistant to degradation from contact with oils, fuels, and various chemicals. This prevents the boot from breaking down and ensures a longer lifespan.

Temperature and Weatherproofing

Many boots incorporate features for environmental comfort and safety. This includes full waterproofing for wet conditions, as well as cold or heat insulation to protect workers in extreme temperatures.

Understanding the Trade-offs

Choosing safety footwear involves balancing competing needs. More protection in one area can sometimes mean a compromise in another.

Steel vs. Composite: The Core Debate

Steel offers maximum protection at a lower cost but is heavier and conducts temperature. Composite is lighter, better for metal-free environments, and provides insulation, but can be bulkier and more expensive.

The Cost of Specialization

A boot with every single protective feature would be incredibly heavy, stiff, and expensive. The goal is not to find a boot that does everything, but to identify the primary hazards of your job and select the boot that specifically addresses them.

Waterproofing vs. Breathability

A fully waterproof membrane is excellent for keeping feet dry from external moisture. However, this can sometimes reduce breathability, trapping sweat and leading to discomfort over long shifts in warm conditions.

Selecting the Right Protection for Your Environment

Your choice should be dictated entirely by the risks you face daily. Analyze your workplace to determine your non-negotiable safety needs.

- If your primary focus is construction or manufacturing: Prioritize a certified toe cap (steel or composite) for impact and a puncture-resistant midsole.

- If your primary focus is electrical work: You must select boots with a certified Electrical Hazard (EH) rating to protect against shock.

- If your primary focus is working outdoors or in wet conditions: Look for boots with a high slip-resistance rating (SRC) and proven waterproofing.

- If your primary focus is around vehicles or machinery: Ensure the outsole is explicitly rated for resistance to oil and fuel.

By matching the boot's features to your specific hazards, you transform it from simple footwear into a critical piece of personal protective equipment.

Summary Table:

| Protection Type | Key Feature | Common Applications |

|---|---|---|

| Impact & Compression | Reinforced Toe Cap (Steel/Composite) | Construction, Manufacturing |

| Puncture & Penetration | Midsole Plate (Steel/Kevlar) | Construction, Demolition |

| Slip & Fall Prevention | Slip-Resistant Outsole (SRC Rating) | Food Service, Outdoor Work |

| Electrical Hazards | EH-Rated Construction | Electrical Work, Utilities |

| Chemical/Environmental | Oil/Fuel Resistance, Waterproofing | Automotive, Chemical Handling |

Need safety boots that match your specific workplace hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the precise protection your team needs—without paying for unnecessary features.

Contact us today for a consultation and let us help you equip your workforce with durable, compliant, and purpose-built safety footwear.

Visual Guide

Related Products

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Durable Steel Toe Safety Boots Wholesale & Custom Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- Why is it necessary to balance safety shoe protection with flexibility? Optimize Worker Comfort and Agility

- How does the calculation of RCOF peak inform safety shoe design? Engineering Grip for High-Intensity Safety

- Why is the use of electrical insulating shoes and gloves essential for industrial printing? Secure Your Safety Barrier

- What features should manufacturing workers consider for comfort in their protective footwear? Prioritize Support & Safety

- What are the technical advantages of using puncture-resistant composite midsoles in safety footwear? | Lightweight Power

- What are the key ASTM standards for protective footwear compliance? Ensure Workplace Safety & OSHA Compliance

- How can the lifespan of work shoes be extended? A Proactive Maintenance Guide

- Why are industrial-grade safety shoes essential for metal stamping? Prevent Injuries with Advanced Protection