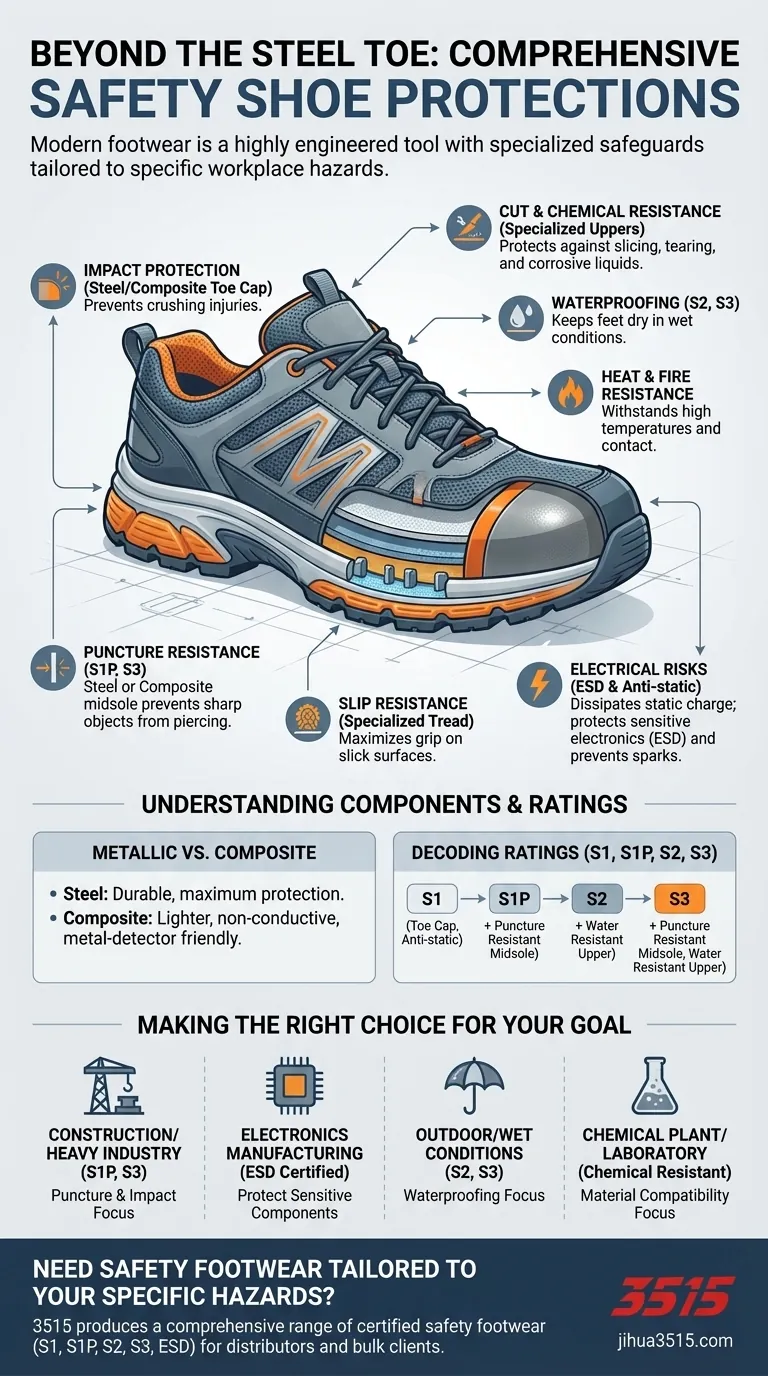

Beyond basic impact protection, modern safety shoes offer a comprehensive suite of specialized safeguards tailored to specific workplace hazards. These additional protections include resistance to punctures from below, slips and falls, electrical discharge, chemical spills, and extreme temperatures, transforming the shoe from a simple guard into a highly specialized piece of personal protective equipment.

The core takeaway is that "safety shoe" is a broad category, not a single product. The right footwear is a highly engineered tool designed for a specific environment, and selecting the correct one requires matching its specific protective features to the known hazards of your workplace.

Beyond the Steel Toe: A Spectrum of Protection

While the reinforced toe cap is the most famous feature, the true value of a safety shoe lies in its ability to counter a wide range of less obvious but equally dangerous risks. These protections are built into the sole, midsole, and upper materials.

Resisting Common Workplace Hazards

Puncture resistance is a critical feature for environments with sharp debris like nails or metal shavings. A steel or composite midsole is embedded in the sole to prevent sharp objects from piercing through to your foot.

Slip resistance is one of the most vital safety features, designed to prevent falls on wet, oily, or otherwise slick surfaces. The outsole is engineered with specific materials and tread patterns to maximize grip.

Chemical resistance is essential when handling corrosive or hazardous liquids. Materials like specialized rubber or neoprene are used to create a barrier, protecting the wearer from chemical burns and exposure.

Guarding Against Environmental Extremes

Heat and fire resistance are crucial for workers in fields like welding or firefighting. These shoes use fire-retardant materials and soles that can withstand contact with high-temperature surfaces.

Waterproofing provides a barrier against liquids, keeping feet dry and comfortable in wet conditions. This is often achieved through treated leathers or built-in waterproof membranes, commonly seen in shoes with an S2 rating or higher.

Cut resistance is another specialized feature, particularly for industries like glass handling or meat processing. The shoe's upper is made from materials that resist slicing or tearing from sharp tools.

Managing Electrical Risks

Anti-static properties are designed to dissipate the body's static electricity charge in a controlled manner. This prevents static buildup and reduces the risk of igniting flammable materials or vapors from an electrostatic spark.

Electrostatic Dissipative (ESD) footwear offers a more tightly controlled level of resistance. Its primary purpose is to protect sensitive electronic components from damage caused by even small static discharges from the wearer's body.

Understanding the Trade-offs

Choosing the right shoe involves understanding the materials and rating systems that define its capabilities. Not all safety shoes are created equal, and a feature that is critical for one job may be unnecessary for another.

Metallic vs. Non-Metallic Components

Many safety shoes use a steel toe cap and a steel midsole for impact and puncture protection. These are extremely durable and offer maximum protection.

However, composite (non-metallic) components are increasingly popular. They are lighter, do not conduct electricity, and won't set off metal detectors, making them ideal for certain secure or electrical environments.

The Importance of the Outsole

The outsole is the shoe's interface with the ground and is engineered for more than just durability. Its design dictates slip resistance, oil resistance, and its ability to absorb shock, reducing fatigue over a long day.

Decoding the Safety Ratings

To standardize these protections, safety footwear is classified into internationally recognized categories, such as S1, S1P, S2, and S3. Each code represents a specific combination of safety features. For example, an S3-rated boot includes a protective toe cap, anti-static properties, a puncture-resistant midsole, and water resistance.

Making the Right Choice for Your Goal

Your choice must be driven by a clear assessment of your environment's specific risks.

- If your primary focus is construction or heavy industry: You need footwear with puncture resistance and a protective toe cap, such as those with an S1P or S3 rating.

- If your primary focus is electronics manufacturing: You must select shoes with certified ESD properties to protect sensitive components.

- If your primary focus is working outdoors or in wet conditions: Look for a shoe with a water-resistant upper, indicated by an S2 or S3 rating.

- If your primary focus is a chemical plant or laboratory: Your priority should be shoes made from rubber or other materials specifically rated for chemical resistance.

Ultimately, selecting the correct safety footwear is a critical decision that directly impacts your personal safety and well-being.

Summary Table:

| Protection Feature | Key Benefit | Common Rating/Use Case |

|---|---|---|

| Puncture Resistance | Prevents sharp objects from piercing the sole | S1P, S3 (Steel/Composite Midsole) |

| Slip Resistance | Reduces falls on wet or oily surfaces | Outsoles with specialized tread patterns |

| Chemical Resistance | Protects against corrosive liquids | Rubber/Neoprene uppers |

| Heat/Fire Resistance | Withstands high temperatures | Welding, firefighting environments |

| ESD / Anti-Static | Controls static electricity to protect electronics | ESD-certified for electronics manufacturing |

| Waterproofing | Keeps feet dry in wet conditions | S2, S3 ratings |

Need Safety Footwear Tailored to Your Specific Hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered to meet S1, S1P, S2, S3, and ESD standards.

We help you:

- Mitigate workplace risks with footwear designed for your specific hazards—be it chemicals, electrical risks, or sharp debris.

- Ensure compliance and comfort with durable, purpose-built designs that keep your team safe and productive.

- Source reliably at scale with consistent quality and volume for your distribution or corporate needs.

Let's discuss your requirements: Contact our team today for expert guidance and custom manufacturing solutions.

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What role do industrial-grade safety shoes play in risk management within the concrete industry Occupational Health and Safety Management System (SMK3)? Elevate Safety & Compliance

- What are the common lower limb injuries among motorcyclists? Protect Yourself from Severe Fractures

- How does the 10-meter walk test reflect the impact of safety shoes on operational efficiency? Maximize Worker Mobility

- Why are professional safety shoes mandatory in food processing? Essential protection for washing, frying, and storage

- How do safety shoes promote stability and ankle support? Secure Your Stance on Any Terrain

- What protective features do high-performance safety shoes provide for ITS sites? Boost On-Site Safety and Stability

- What changes does the new EN ISO 20345 standard introduce regarding the FO marking? It's now optional.

- How does the flexibility design of industrial safety shoes assist shipyard electricians? Boost Agility & Back Health