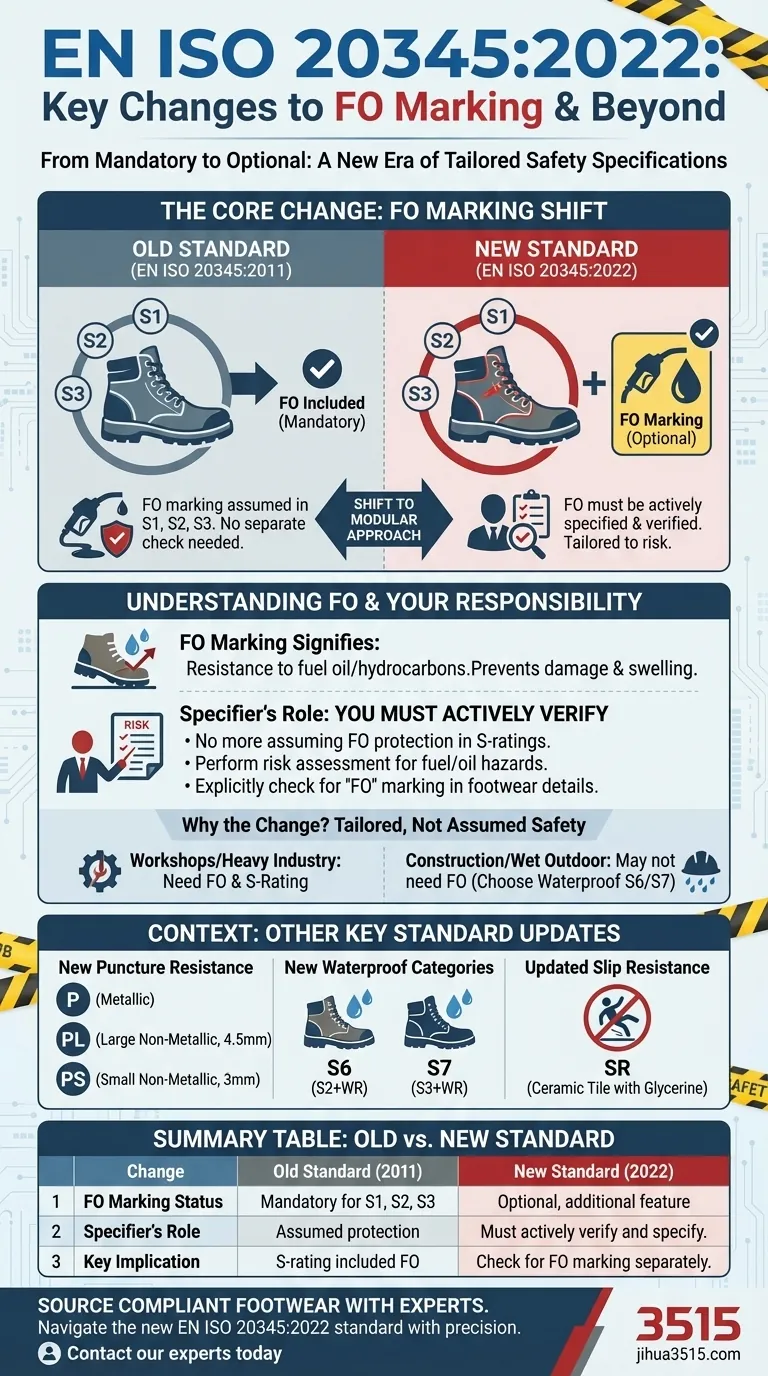

Under the new EN ISO 20345:2022 standard, the most significant change is that the FO marking is no longer a mandatory component of the S1, S2, and S3 safety footwear classifications. This means that soles resistant to hydrocarbons (fuel oil) are now an optional, additional feature that must be specified separately, rather than being an assumed part of these common safety levels.

The core principle of the new standard is a shift from bundled, assumed protections to a more modular approach. This gives you more precise control over specifying features like hydrocarbon resistance, but it also places the responsibility on you to actively verify that every required feature is present.

The Shift from Mandatory to Optional

The previous version of the standard simplified purchasing by including certain features automatically within specific S-ratings. The update unbundles these features to allow for more tailored and accurate safety specifications based on actual workplace risks.

What the FO Marking Signifies

The FO marking indicates that the outsole of the safety footwear has been tested and shows resistance to damage and swelling when exposed to hydrocarbons, such as fuel oil.

The Old Standard: Mandatory Inclusion

Under the previous EN ISO 20345:2011, fuel oil resistance was a required characteristic for any footwear certified as S1, S2, or S3. If you purchased an S3 boot, for example, you could assume it had FO protection.

The New Standard: An Additional Requirement

Under the current EN ISO 20345:2022 standard, FO is now treated as an independent, optional test. A boot can be certified as S1, S2, or S3 without having a fuel-oil-resistant sole. If this protection is needed, the footwear must explicitly carry the FO marking in addition to its S-rating.

Why This Change Matters in Practice

This update fundamentally changes how you should approach specifying and verifying safety footwear. It moves the industry away from a "one-size-fits-all" model for S-ratings toward a more precise, risk-based selection process.

The Goal: Tailored, Not Assumed, Safety

The logic behind this change is to ensure footwear is not over-specified. Many work environments require a safety toe and puncture resistance but have no risk of hydrocarbon exposure. Separating the FO marking allows for more cost-effective and appropriate footwear selection for those roles.

Your Responsibility as a Specifier

The primary implication is that you can no longer assume an S1, S2, or S3 shoe is suitable for environments with fuel or oil. You must now perform a risk assessment and, if hydrocarbon exposure is a hazard, actively look for the FO marking on the product's certification details.

Context: Other Key Changes in the Standard

The change to the FO marking is part of a larger update designed to provide greater clarity and precision. Understanding these related changes is crucial for making informed decisions.

New Puncture Resistance Markings

Previously, P indicated puncture resistance from a 4.5 mm nail. This now only applies to metallic inserts. Non-metallic inserts have two new codes:

- PL: Resistance to a large 4.5 mm nail.

- PS: Resistance to a small 3 mm nail.

New Waterproofing Categories

The standard introduces entirely new categories for footwear with integrated waterproof membranes:

- S6: Has the requirements of S2 plus water resistance (WR).

- S7: Has the requirements of S3 plus water resistance (WR).

Updated Slip Resistance Marking

The previous SRA, SRB, and SRC markings have been removed. All footwear must now pass a basic slip test. If additional slip resistance is tested and passed on a ceramic tile with glycerine, it will be marked with SR.

Understanding the Trade-offs

This new, more modular standard offers significant benefits but requires a more diligent approach to procurement.

Benefit: Increased Flexibility

You now have the ability to select footwear that is precisely matched to your workplace hazards without paying for unnecessary features. This can lead to better long-term value and user comfort.

Drawback: Increased Responsibility

The burden of due diligence is now higher. You must analyze your risk assessment more closely and check the full marking string of the footwear (e.g., S3S PL SR FO), not just the primary S-rating.

Pitfall: Avoiding Complacency

It is critical to avoid assuming a new shoe model has the same protections as its predecessor. A new boot labeled "S3" may not have the FO or P (metallic) protections that an older S3 boot did, so always verify the full specification.

How to Specify Footwear Under the New Standard

Your selection process should be guided entirely by your workplace risk assessment.

- If your primary focus is work in garages, workshops, or heavy industry: You must actively look for the FO marking in addition to the required S-rating.

- If your primary focus is construction or waste management: You must now decide between metallic (P), large non-metallic (PL), or small non-metallic (PS) puncture resistance.

- If your primary focus is outdoor work in wet conditions without oil hazards: You may not need FO, but you should look for the new waterproof ratings like S6 or S7.

By understanding these deliberate changes, you can specify safety footwear that is precisely suited to your environment's unique risks.

Summary Table:

| Change | Old Standard (EN ISO 20345:2011) | New Standard (EN ISO 20345:2022) |

|---|---|---|

| FO Marking Status | Mandatory for S1, S2, S3 | Optional, additional feature |

| Specifier's Role | Assumed protection | Must actively verify and specify |

| Key Implication | S-rating included FO | Check for FO marking separately |

Need to source safety footwear that precisely matches the new EN ISO 20345:2022 standard?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We ensure every pair meets the exact specifications you require, whether you need FO marking, updated puncture resistance (P, PL, PS), or the new waterproof categories (S6, S7).

Let us help you navigate these changes and provide reliable, compliant footwear for your market.

Contact our experts today to discuss your requirements.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data