Ultimately, you should look for a work boot with a durable construction method like a Goodyear welt, high-quality materials such as full-grain leather, and design features tailored specifically to the demands of your trade. The way the upper is bonded to the outsole is the single most important factor, followed by the quality of the materials used inside and out. A lengthy manufacturer's warranty often serves as a reliable indicator of the maker's confidence in their own construction.

True construction quality isn't found in a single feature, but in the synergy between the boot's bonding method, its materials, and its purpose-built design. A great work boot is a specialized tool where every component is chosen to enhance durability, safety, and repairability for a specific job.

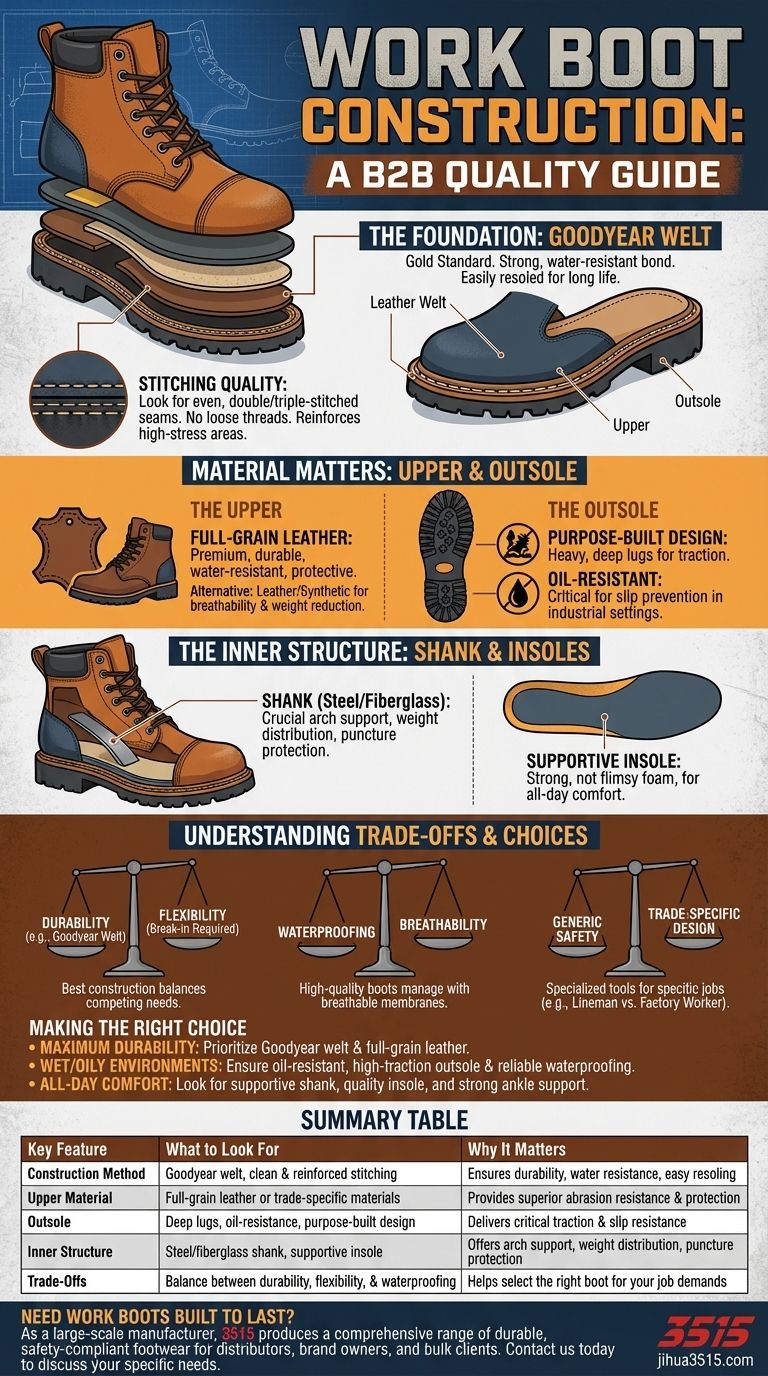

The Foundation: How the Boot is Held Together

The method used to attach the sole of the boot to the upper part is the core of its construction. This determines its durability, water resistance, and whether it can be repaired for a second life.

Goodyear Welt Construction

The Goodyear welt is widely considered the gold standard for high-quality work boots. It uses a strip of leather (the welt) stitched to both the upper and the outsole.

This creates an incredibly strong, water-resistant bond. Most importantly, it allows a cobbler to easily remove the old sole and attach a new one, dramatically extending the boot's lifespan.

Stitching Quality as a Visual Cue

Beyond the specific construction method, pay close attention to the stitching itself. Look for even, clean stitch lines with no loose threads.

High-quality boots will often feature double or triple-stitched seams in high-stress areas. This reinforcement is a clear visual sign that the boot was built to withstand significant wear and tear.

Material Matters: From Upper to Outsole

The materials used are a direct reflection of the boot's intended performance and longevity. Low-quality materials will fail regardless of how well they are stitched together.

The Upper: Your First Line of Defense

The upper is the part of the boot that covers your foot. Full-grain leather is the premium material, offering the best in durability, water resistance, and protection.

Some boots use a combination of leather and synthetic fabric panels. This can reduce weight and improve breathability, but leather generally provides superior protection against abrasion in rocky or rough environments.

The Outsole: Your Connection to the Ground

The outsole must be suited for your work environment. A quality boot will have a sole designed for a specific purpose.

Look for heavy, deep lugs for traction on uneven or loose terrain. If you work around machinery or vehicles, an oil-resistant outsole is a critical safety feature to prevent slips.

The Inner Structure: Shanks and Insoles

Hidden components are just as critical. A shank, a stiff piece of material (often steel or fiberglass) placed in the midsole, provides crucial arch support and helps distribute weight evenly.

This feature prevents foot fatigue during long days and protects your feet from puncture injuries from below. A quality boot will also feature a strong, supportive insole, not a flimsy foam insert.

Understanding the Trade-offs

Choosing the right boot means understanding that no single design is perfect for every situation. The best construction is one that balances competing needs based on your specific job.

Durability vs. Flexibility

The most durable construction methods, like the Goodyear welt, often result in a stiffer boot that requires a break-in period. Lighter, more flexible boots may feel more comfortable out of the box but often sacrifice long-term resilience and repairability.

Waterproofing vs. Breathability

A truly waterproof boot is excellent for wet conditions but can trap sweat, leading to discomfort. High-quality boots manage this with breathable waterproof membranes and moisture-wicking linings, but there is always a trade-off.

Generic Safety vs. Trade-Specific Design

A generic "safety boot" is not a specialized tool. The construction needs of a lineman who needs ankle support for climbing poles are vastly different from those of a factory worker who needs a slip-resistant sole for concrete floors. The highest quality boots are designed with a specific trade in mind.

Making the Right Choice for Your Job

Your final decision should be guided by the unique demands of your workday. Focus on the features that provide the most benefit for the tasks you perform most often.

- If your primary focus is maximum durability and longevity: Prioritize a boot with a Goodyear welt construction and a full-grain leather upper, as this combination is the most resilient and repairable.

- If your primary focus is working in wet or oily environments: Ensure the boot has an oil-resistant, high-traction outsole and a reliable waterproofing system.

- If your primary focus is all-day comfort and support: Look for a boot with a supportive shank, a quality insole, and strong ankle support to reduce fatigue.

Ultimately, investing in a well-constructed work boot is an investment in your own safety, comfort, and productivity.

Summary Table:

| Key Feature | What to Look For | Why It Matters |

|---|---|---|

| Construction Method | Goodyear welt, clean & reinforced stitching | Ensures durability, water resistance, and allows for easy resoling |

| Upper Material | Full-grain leather or trade-specific materials | Provides superior abrasion resistance and protection |

| Outsole | Deep lugs, oil-resistance, purpose-built design | Delivers critical traction and slip resistance for your environment |

| Inner Structure | Steel/fiberglass shank, supportive insole | Offers arch support, weight distribution, and puncture protection |

| Trade-Offs | Balance between durability, flexibility, and waterproofing | Helps select the right boot for your specific job demands |

Need work boots built to last?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, safety-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities cover all types of work boots and shoes, ensuring top-tier construction quality tailored to your trade’s demands.

Contact us today to discuss your specific needs and benefit from our expertise in creating long-lasting, high-performance work footwear.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What are some features of men's cowboy boots? A Guide to Shafts, Heels, and Toes

- What are the specific requirements for wildland firefighting boots under NFPA 1977? Essential Safety Guide

- What is the best material for work boots and why? Match the Material to Your Job's Hazards

- What are the different materials used to make work boots? Choose the Right Boot for Your Job

- What are the advantages of leather work boots for farm work? Unmatched Durability & Protection

- What are the benefits of wedge soles in moc toe boots? Superior Comfort for Hard Surfaces

- What comfort features do pull-on work boots offer? Unlock All-Day Comfort and Convenience

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety