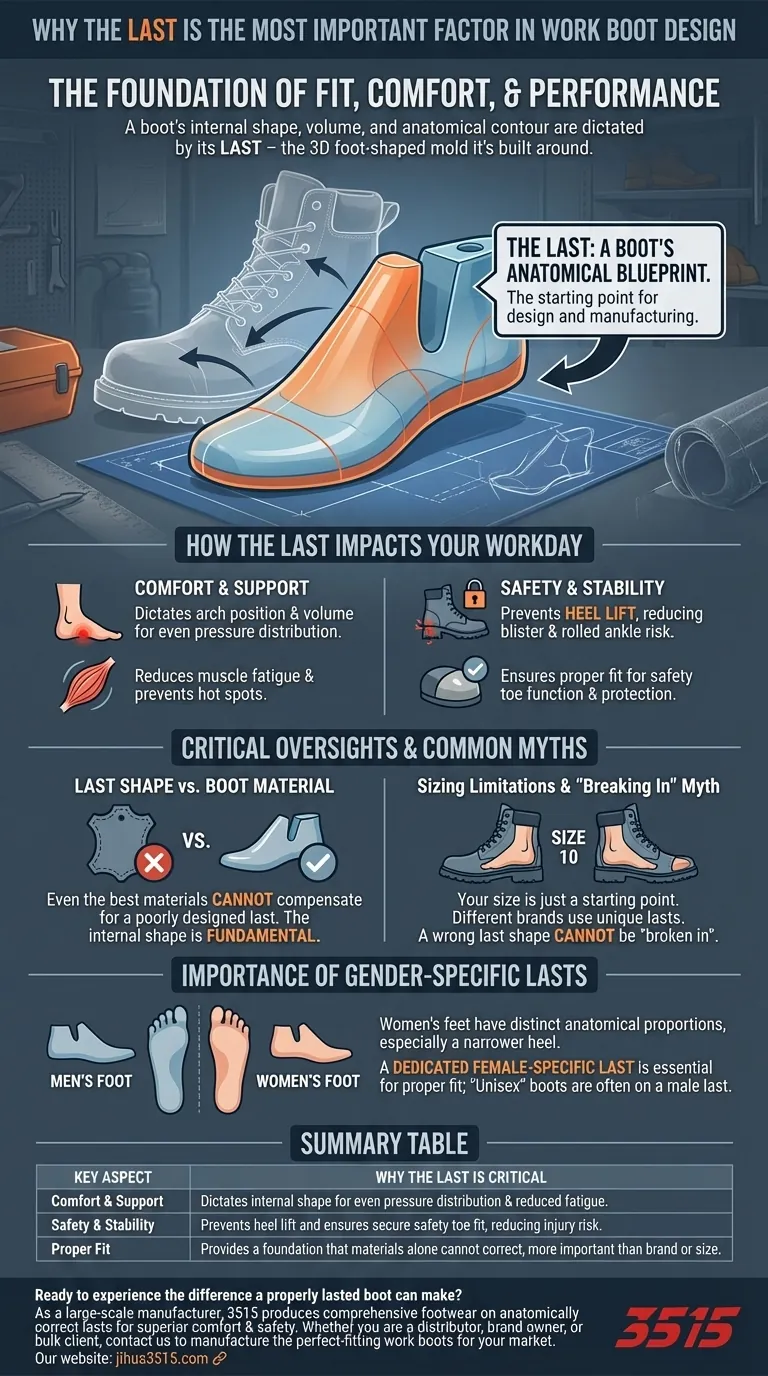

The single most important factor in the fit, comfort, and performance of any work boot is the last. A last is the three-dimensional, foot-shaped mold that a boot is built around. It is the foundational blueprint that dictates the boot's entire internal shape, volume, and anatomical contour, directly influencing how it supports your foot all day.

The last is the boot's fundamental anatomy. Choosing footwear built on a last that correctly matches your foot's geometry is the most critical decision for ensuring long-term comfort, support, and safety.

The Last: A Boot's Anatomical Blueprint

To understand why some boots feel perfect and others cause persistent pain, you must first understand the role of the last. It is the starting point for the entire design and manufacturing process.

What Exactly is a Boot Last?

Think of the last as the "formwork" for a concrete foundation. Every component of the boot—the leather, the sole, the heel counter—is stretched, stitched, and molded around this solid form.

Once the boot is constructed, the last is removed, leaving behind an internal cavity that is a direct copy of its shape. This cavity becomes the space your foot occupies.

Why It Dictates Everything

The last determines every critical dimension of the boot's interior. This includes the width of the heel, the height of the instep, the position of the arch, and the volume and shape of the toe box.

A well-designed last provides support in the right places and room where your foot needs to flex and expand naturally.

The Myth of "Breaking In"

Many believe a painful boot can be "broken in." While materials like leather will soften over time, this process cannot change the fundamental geometry established by the last.

If the last's shape is fundamentally wrong for your foot, no amount of breaking in will correct a poorly placed arch or a cramped toe box.

From Blueprint to Performance: How the Last Impacts Your Workday

The invisible shape of the last has a very visible impact on your daily experience, affecting everything from comfort to on-the-job safety.

The Foundation of Comfort and Support

All-day comfort comes from a boot that works with your foot's anatomy, not against it. A boot built on an anatomically correct last will feel supportive right out of the box.

It distributes pressure evenly across the sole of your foot, preventing the development of painful hot spots and reducing overall muscle fatigue.

A Critical Factor in Safety

Proper fit is a non-negotiable safety feature. A boot built on the wrong last can lead to heel lift, where your heel slips up and down as you walk. This not only causes blisters but also creates instability, increasing the risk of a rolled ankle.

Likewise, an improperly shaped toe box can pinch your toes or allow too much movement, compromising the protective function of a safety toe.

The Importance of Gender-Specific Lasts

Men's and women's feet have different anatomical proportions. A woman's foot typically has a narrower heel in relation to the forefoot.

Using a dedicated female-specific last is crucial for creating a proper fit for women. Boots marketed as "unisex" are almost always built on a male last, which can result in poor heel lock and general discomfort for female wearers.

Understanding the Common Oversights

When selecting work boots, it's easy to focus on external features. However, understanding the central role of the last helps you avoid common purchasing mistakes.

Last Shape vs. Boot Material

Even the highest quality leather or most advanced materials cannot compensate for a poorly designed last. The internal shape is more important than the materials wrapped around it.

Prioritizing the foundational fit over surface-level features is essential for making a sound investment in your footwear.

The Limitation of Sizing

A "size 10" from one brand can feel completely different from another's. This is because each brand uses its own proprietary lasts with unique dimensions.

Your shoe size is just a starting point. The true measure of a boot is how the shape of its last corresponds to the shape of your foot.

How to Choose a Boot Based on Fit, Not Just Features

Use your understanding of the last to make a more informed choice that prioritizes the health and comfort of your feet.

- If your primary focus is all-day comfort: Prioritize brands known for their commitment to anatomically correct, gender-specific lasts over those that only highlight materials or style.

- If your primary focus is safety and stability: Ensure the boot's heel and toe box, which are shaped by the last, fit securely without causing excessive movement or pinching.

- If you are trying a new brand: Recognize that your standard size may not fit correctly due to a different last, and always prioritize the actual feel over the number on the box.

Understanding the last empowers you to look beyond surface features and choose a work boot built for the unique shape of your foot.

Summary Table:

| Key Aspect | Why the Last is Critical |

|---|---|

| Comfort & Support | Dictates internal shape, arch position, and volume for even pressure distribution and reduced fatigue. |

| Safety & Stability | Prevents heel lift and ensures a secure fit around the toe box, reducing the risk of injury. |

| Proper Fit | A well-designed last provides a foundation that materials alone cannot correct, making it more important than brand or size. |

Ready to experience the difference a properly lasted boot can make?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear built on anatomically correct lasts designed for superior comfort and safety. Whether you are a distributor, brand owner, or bulk client, our production capabilities encompass all types of work boots tailored to your specific needs.

Contact us today to discuss how we can manufacture the perfect-fitting work boots for your market.

Visual Guide

Related Products

- Wholesale Durable 6-Inch Work Boots | Custom & Private Label Manufacturer

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Steel Toe Safety Boots Wholesale & Custom Manufacturing

People Also Ask

- What are the signs that work boots need replacement? Protect Your Feet and Safety on the Job

- Are safety toe options available for women's work boots? A Guide to Steel, Composite & Alloy Toes

- How do work boots differ from cowboy boots? Choosing the Right Footwear for Your Job

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort