There is no single "best" material for all work boots. The ideal choice depends entirely on your specific work environment and the primary hazards you face. While full-grain leather is the traditional and most versatile option for its balance of durability and comfort, specialized synthetic materials like rubber, PVC, and neoprene offer superior performance for specific conditions like chemical exposure or extreme cold.

The core takeaway is to shift from asking "what is the best material?" to "what is the right material for my job?" Your selection should be a deliberate choice that matches the material's strengths directly to the unique demands and risks of your workplace.

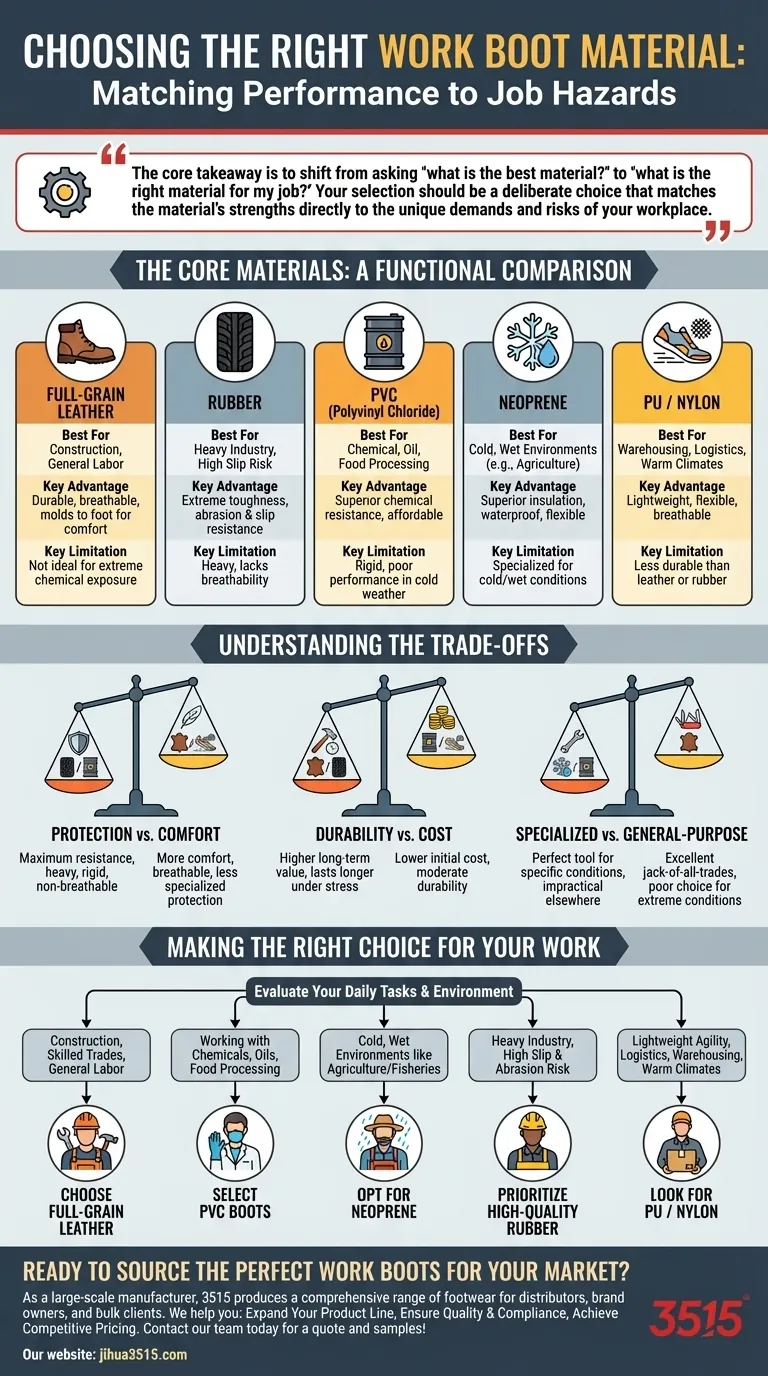

The Core Materials: A Functional Comparison

Understanding the primary function of each material is the key to making an informed decision. Each excels in a different domain of protection and comfort.

For All-Around Durability and Comfort: Leather

Full-grain leather is the benchmark for general-purpose work boots. Its primary advantage is its ability to be both tough and breathable.

Over time, leather molds to the unique shape of your foot, providing a custom fit and unparalleled long-term comfort. This makes it ideal for long days on your feet in construction or general labor.

For Maximum Physical Toughness and Grip: Rubber

When the job demands extreme durability against abrasion and wear, rubber is the top performer. Vulcanized rubber, in particular, is exceptionally tough.

Rubber also provides excellent slip resistance and impact protection, making it a staple for heavy-duty work. It is naturally waterproof but is also heavy and lacks breathability.

For Unmatched Chemical Resistance: PVC

Polyvinyl Chloride (PVC) is the definitive choice for environments with chemical hazards. It offers robust protection against oils, animal fats, acids, and other corrosive substances.

While highly protective and affordable, PVC is less flexible and comfortable than other materials and offers poor performance in cold weather.

For Superior Insulation in Cold & Wet Conditions: Neoprene

Neoprene is the premier material for boots used in cold, wet environments. It is a fantastic insulator that traps warmth effectively.

Its flexibility also ensures a snug fit around the foot and calf, preventing heat loss and keeping you comfortable in freezing or wet conditions.

For Lightweight Flexibility: PU and Nylon

Polyurethane (PU) is a synthetic material that mimics the feel of leather but is significantly lighter and more flexible. It offers a good balance of durability and comfort for less demanding jobs.

Nylon is often integrated into leather or synthetic boots to reduce weight and dramatically increase breathability, making it ideal for warmer climates or indoor work.

Understanding the Trade-offs

Selecting a work boot material is always a matter of balancing competing priorities. Being aware of these trade-offs is essential.

Protection vs. Comfort

The most fundamental trade-off is between absolute protection and all-day comfort. Materials like rubber and PVC offer maximum resistance to physical and chemical hazards but are often heavy, rigid, and non-breathable.

Conversely, leather, PU, and nylon provide significantly more comfort and breathability but offer less specialized protection against extreme conditions.

Durability vs. Cost

While a less expensive PVC boot may be tempting, it typically offers only moderate durability compared to high-quality rubber or leather. Investing in a more durable material often results in a lower long-term cost, as the boots will last longer under stress.

Specialized vs. General-Purpose

A neoprene boot is the perfect tool for a worker in a cold storage facility but is impractical and uncomfortable for a roofer on a hot day. A general-purpose leather boot is an excellent jack-of-all-trades but is a poor choice for a chemical processing plant. The key is to avoid using a specialized boot for the wrong application.

Making the Right Choice for Your Work

Evaluate your daily tasks and environment, then select the material that best aligns with your primary need for protection and performance.

- If your primary focus is construction, skilled trades, or general labor: Choose full-grain leather for its superior balance of durability, support, and long-term comfort.

- If your primary focus is working with chemicals, oils, or in food processing: Select PVC boots for their unmatched chemical resistance and ease of cleaning.

- If your primary focus is working in cold, wet environments like agriculture or fisheries: Opt for Neoprene for its superior insulation and flexible, waterproof comfort.

- If your primary focus is heavy industry or work with high slip and abrasion risk: Prioritize high-quality rubber for its extreme toughness and reliable grip.

- If your primary focus is lightweight agility in logistics, warehousing, or warm climates: Look for boots made with PU or featuring nylon panels for breathability and reduced fatigue.

Choosing the right material is the first and most critical step in ensuring your safety, comfort, and performance on the job.

Summary Table:

| Material | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| Full-Grain Leather | Construction, General Labor | Durable, breathable, molds to foot for comfort | Not ideal for extreme chemical exposure |

| Rubber | Heavy Industry, High Slip Risk | Extreme toughness, abrasion & slip resistance | Heavy, lacks breathability |

| PVC | Chemical, Oil, Food Processing | Superior chemical resistance, affordable | Rigid, poor performance in cold weather |

| Neoprene | Cold, Wet Environments (e.g., Agriculture) | Superior insulation, waterproof, flexible | Specialized for cold/wet conditions |

| PU / Nylon | Warehousing, Logistics, Warm Climates | Lightweight, flexible, breathable | Less durable than leather or rubber |

Ready to Source the Perfect Work Boots for Your Market?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and work boots, ensuring you get the right material and construction for your customers' needs.

We help you:

- Expand Your Product Line: Offer a complete range from durable leather to specialized PVC and insulated neoprene boots.

- Ensure Quality and Compliance: Benefit from our expertise in manufacturing boots that meet rigorous safety standards.

- Achieve Competitive Pricing: Leverage our scale for cost-effective bulk orders and reliable supply.

Let's discuss your specific requirements. Contact our team today to get a quote and samples!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- Why is high abrasion resistance essential for professional work boots in volcanic regions? Maximize Durability & Safety

- Why are ergonomic design and comfort critical for safety boot compliance? Boost Worker Safety and Adoption Rates

- What are the main factors to consider when selecting work boots? A Guide to Safety, Comfort & Durability

- How do wildland firefighting boots differ from other firefighting boots? Key Design & Safety Differences

- What are the characteristics of synthetic/leather boots? Modern Performance Meets Lightweight Durability

- What should be considered when choosing PVC work boots? Select the Right Boot for Your Job Hazards

- Do work boot manufacturers use the same construction methods? Choose the Right Foundation for Your Job

- How do wildfire boots protect feet from extreme heat? A Multi-Layer Defense System Explained