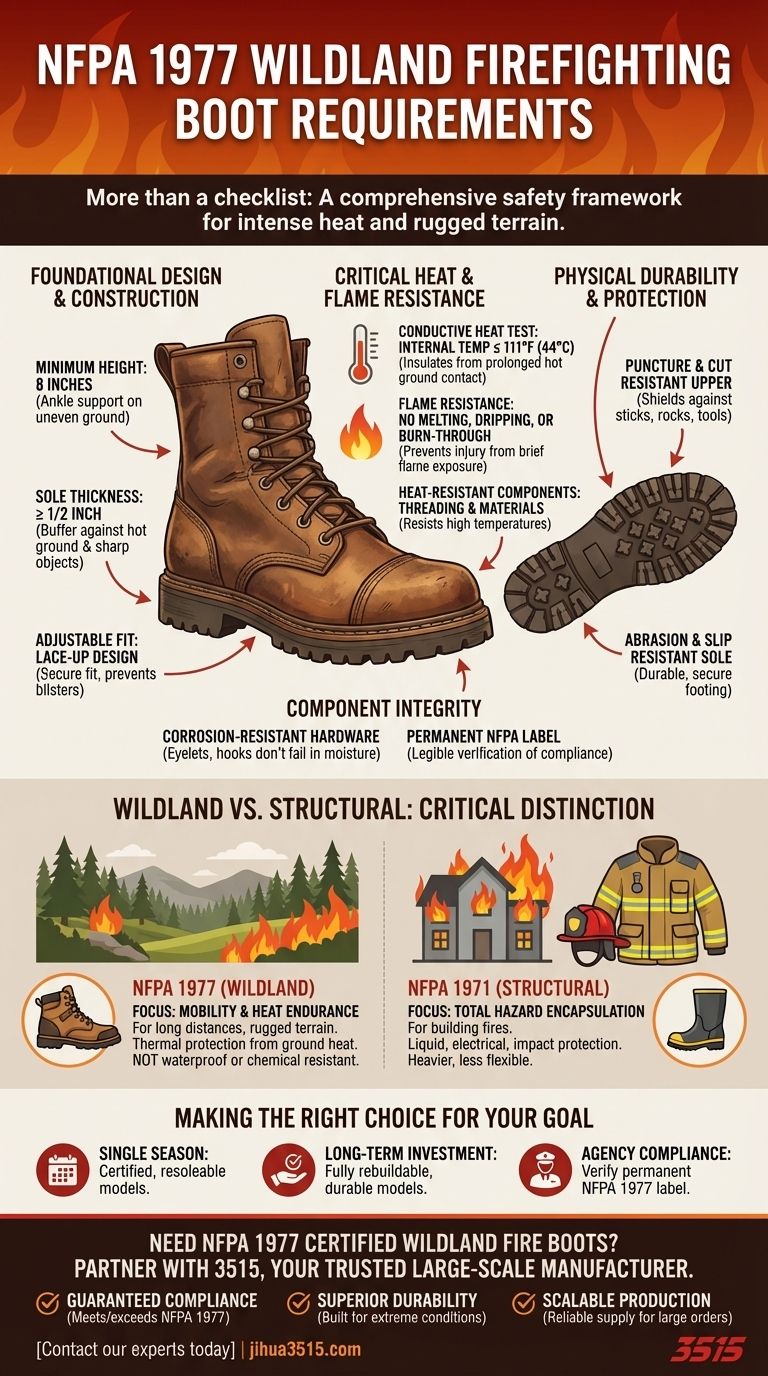

To meet the NFPA 1977 standard, a wildland firefighting boot must be a lace-up leather model with a minimum height of 8 inches and a sole at least a half-inch thick. Crucially, it must pass a battery of performance tests certifying its resistance to heat, flame, puncture, and cuts. Every component, from the threading to the metal eyelets, must be independently tested to ensure it will not fail under extreme fireline conditions.

The NFPA 1977 standard is more than a simple checklist; it is a comprehensive safety framework. It ensures a boot is not just a piece of footwear, but an integrated system of protection designed specifically for the unique combination of intense heat and rugged terrain encountered in wildland firefighting.

Deconstructing the NFPA 1977 Standard

The requirements set by the National Fire Protection Association (NFPA) are designed to protect firefighters from the most common and severe hazards they face. Each specification addresses a specific risk on the fireline.

Foundational Design and Construction

- Minimum Height: Boots must measure at least 8 inches from the bottom of the heel to the top of the boot. This provides essential ankle support and stability on steep, uneven ground, helping to prevent sprains and injuries.

- Sole Thickness: The sole must be at least 1/2-inch thick. This provides a critical buffer between the foot and hot ground, as well as protection from sharp objects underfoot.

- Adjustable Fit: The standard specifies a lace-up design to ensure a secure, adjustable fit that prevents shifting and blisters during long hours of hiking and working.

Critical Heat and Flame Resistance

- Conductive Heat Test: This is a key performance metric. During testing, the temperature on the inside bottom of the boot cannot exceed 111°F (44°C). This ensures the sole can insulate the foot from prolonged contact with hot ground and embers.

- Flame Resistance: When exposed to a direct flame for under 5 seconds, the boot materials must not melt, drip, or burn through. This test confirms the boot will not contribute to an injury during brief, direct contact with fire.

- Heat-Resistant Components: All threading used in the boot's construction must be inherently heat-resistant to prevent seams from failing when exposed to high temperatures.

Physical Durability and Protection

- Puncture Resistance: The upper part of the boot must be certified as puncture-resistant, protecting the foot from sharp sticks, rocks, and debris common in wildland environments.

- Cut Resistance: The boot's upper must also demonstrate a high degree of cut resistance, safeguarding against lacerations from tools or jagged terrain.

- Abrasion and Slip Resistance: The sole is required to be both abrasion-resistant for durability and slip-resistant to provide secure footing on loose or challenging surfaces.

Component Integrity

- Corrosion Resistance: All metal parts, such as hooks and eyelets, must be corrosion-resistant to prevent failure due to moisture and environmental exposure.

- Hardware Strength: These same eyelets and hooks must pass rigorous attachment strength tests to ensure they will not pull out or break under high stress.

- Permanent Label: Every certified boot must have an NFPA label permanently affixed to the interior that remains legible throughout the life of the boot, providing a clear verification of its compliance.

Understanding the Critical Distinction: Wildland vs. Structural Boots

It is vital to understand that NFPA 1977 is a specific standard for wildland firefighting. It should not be confused with NFPA 1971, the standard for structural firefighting gear, as the boots are designed for entirely different environments and hazards.

NFPA 1977 (Wildland): Focus on Mobility and Heat Endurance

Wildland boots are built for mobility over long distances on rugged terrain. Their primary function is to provide thermal protection from ground heat and embers while remaining durable and supportive enough for what is essentially extreme hiking. They are not designed to be waterproof or provide protection from chemical or bloodborne pathogens.

NFPA 1971 (Structural): Focus on Total Hazard Encapsulation

Structural boots, often rubber pull-on models, are designed for protection against a wider array of hazards found in building fires. They feature requirements for liquid penetration resistance, electrical insulation, and impact protection. This makes them heavier, less flexible, and poorly suited for the long-distance travel required in wildland operations.

Making the Right Choice for Your Goal

Selecting a boot that meets the NFPA 1977 standard is non-negotiable for safety and compliance. Your choice within that category will depend on your specific needs and expected use.

- If your primary focus is meeting the minimum requirement for a single season: Look for a certified, resoleable boot that provides the necessary protection without the higher cost of a fully rebuildable model.

- If your primary focus is long-term investment and career use: Prioritize a fully rebuildable NFPA-approved boot known for its durability, which will last for many seasons with proper care.

- If your primary focus is agency compliance and procurement: Always verify the permanent, sewn-in NFPA 1977 label inside the boot to ensure you are purchasing authentic, certified equipment for your personnel.

Choosing a boot that meets the NFPA 1977 standard is the foundational step in ensuring your safety and effectiveness on the fireline.

Summary Table:

| Requirement | Key Specification | Purpose |

|---|---|---|

| Boot Height | Minimum 8 inches | Ankle support and stability on rugged terrain |

| Sole Thickness | At least 1/2 inch | Insulation from hot ground and protection from sharp objects |

| Heat Resistance | Internal temp ≤ 111°F (44°C) | Protects feet from prolonged contact with hot surfaces |

| Flame Resistance | No melting, dripping, or burn-through | Prevents injury from brief, direct flame contact |

| Physical Protection | Puncture and cut-resistant upper | Shields feet from debris, sticks, and sharp rocks |

| Component Integrity | Corrosion-resistant hardware | Ensures durability and reliability in harsh conditions |

Need NFPA 1977 Certified Wildland Fire Boots? Partner with 3515, Your Trusted Large-Scale Manufacturer.

As a leading manufacturer, 3515 produces a comprehensive range of certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots, ensuring your team has the durable, compliant gear they need for the fireline.

We deliver:

- Guaranteed Compliance: Boots that meet and exceed all NFPA 1977 requirements.

- Superior Durability: Built to withstand the extreme conditions of wildland firefighting.

- Scalable Production: Reliable supply for large orders and ongoing procurement needs.

Protect your team with confidence. Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- High Performance Fire-Retardant Waterproof Safety Boots

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Lightweight Tactical Boots Custom Manufacturer for Desert & Combat Use

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- How do heavy duty work boots reduce foot fatigue? Maximize Comfort and Endurance on the Job

- What are pull-on work boots? Unlock Speed vs. Support for Your Workforce

- What are the key parts of a work boot's interior? The 3 Core Components for All-Day Comfort & Support

- What was the original purpose of engineer boots? From Industrial Protection to Iconic Style

- What are the key considerations when choosing work boot materials? Find the Perfect Boot for Your Job

- Why are work boots considered essential PPE? Unlock Superior Foot Protection for Your Workforce

- What are the advantages of using PU for work boots? Lightweight Comfort & Durability Explained

- Why are protective work boots essential in certain industries? Protect Your Workforce from Hazards