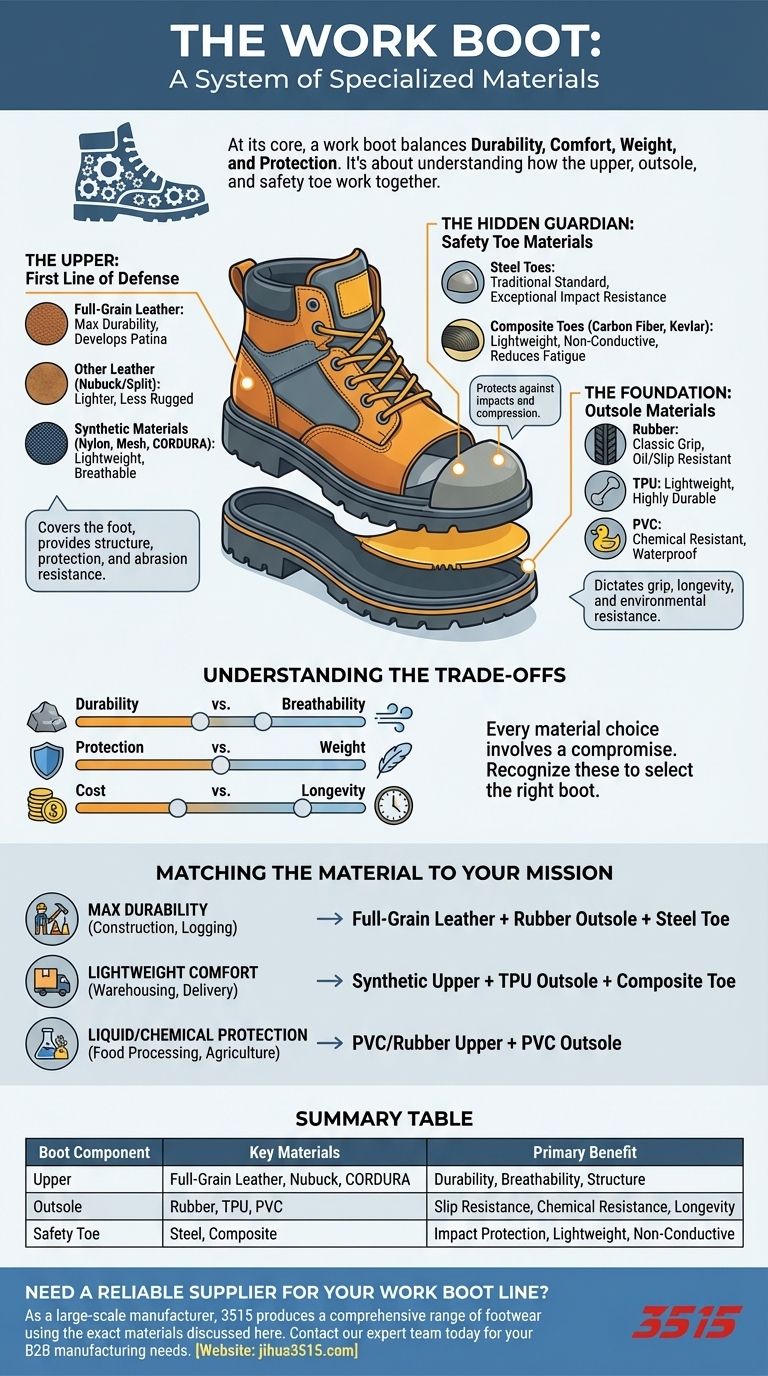

At its core, a work boot is a system of specialized materials. The most common include various types of leather and synthetic fabrics for the upper, rubber or thermoplastic compounds for the outsole, and steel or composites for the protective safety toe. Each material is chosen to balance durability, comfort, weight, and protection for a specific task.

Choosing the right work boot isn't about finding the single "best" material. It's about understanding how the materials in the upper, outsole, and safety toe work together to meet the specific demands of your work environment.

Deconstructing the Work Boot: A Tale of Three Parts

A work boot is more than a single piece of material. It's an assembly of distinct components, each with a critical role. We can break it down into the upper, the outsole, and the safety toe.

The Upper: Your First Line of Defense

The upper is the part of the boot that covers your foot. Its primary job is to provide structure, protection from the elements, and durability against abrasion.

Full-Grain Leather This is the highest quality leather, known for its exceptional durability and ability to develop a patina over time. It offers the best resistance to wear and tear, making it ideal for harsh environments.

Other Leather Variants Boots may also use split-grain or nubuck leather. These are often lighter and more breathable than full-grain leather but offer slightly less ruggedness. "Genuine leather" is a lower-grade material used in more budget-friendly options.

Synthetic Materials Materials like nylon, mesh, or high-performance fabrics like CORDURA are frequently used to reduce weight and significantly increase breathability. They are excellent for light-duty work or jobs requiring a lot of walking.

The Foundation: Understanding Outsole Materials

The outsole is the part of the boot that contacts the ground. Its material dictates grip, longevity, and resistance to environmental factors like oil or chemicals.

Rubber: The Classic Choice for Grip

Rubber is the traditional go-to for outsoles. It provides excellent resistance to abrasions, oil, and slips, making it a reliable choice for a wide range of industrial and outdoor settings.

TPU and PVC: Modern Lightweight Compounds

Thermoplastic Polyurethane (TPU) is a modern material that is lighter than rubber but still highly durable. It has a superior resistance to splitting and cracking. Polyvinyl Chloride (PVC) is another common choice, particularly for boots designed to be fully waterproof and chemical-resistant.

The Hidden Guardian: Safety Toe Materials

For many jobs, the protective toe cap is the most critical safety feature. It's designed to protect your feet from impacts and compression from falling or rolling objects.

Steel Toes: The Traditional Standard

Steel has been the industry standard for decades for a reason: it provides exceptional impact resistance. It sets the benchmark for protection against heavy objects.

Composite Toes: The Lightweight Alternative

Composite toes are made from non-metal materials like carbon fiber, fiberglass, or Kevlar. They are significantly lighter than steel, which reduces foot fatigue, and they do not conduct electricity, making them essential for electricians and workers in high-security environments.

Understanding the Trade-offs

Every material choice involves a compromise. Recognizing these trade-offs is the key to selecting the right boot for your needs.

Durability vs. Breathability

A thick, full-grain leather upper offers maximum durability but can be heavy and warm. In contrast, an upper with synthetic mesh panels provides excellent breathability for comfort but is more susceptible to tearing in rugged conditions.

Protection vs. Weight

Steel toes offer immense protection but add noticeable weight to each boot, which can cause fatigue over a long shift. Lighter composite toes provide certified protection while making the boot feel more agile and comfortable.

Cost vs. Longevity

Premium materials like full-grain leather and high-end synthetics come with a higher initial price tag. However, they often outlast cheaper alternatives, providing better value over the boot's lifespan.

Matching the Material to Your Mission

Your final choice should be guided entirely by the realities of your job.

- If your primary focus is maximum durability in harsh environments (e.g., construction, logging): Prioritize a full-grain leather upper paired with a rugged rubber outsole and a steel toe.

- If your primary focus is lightweight comfort and mobility (e.g., warehousing, delivery driver): Look for boots with synthetic uppers, TPU outsoles, and composite safety toes to minimize fatigue.

- If your primary focus is protection from liquids or chemicals (e.g., food processing, agriculture): Choose a boot constructed primarily from waterproof rubber or PVC.

Understanding these materials empowers you to choose a tool, not just a boot, that is perfectly suited for the demands of your work.

Summary Table:

| Boot Component | Key Materials | Primary Benefit |

|---|---|---|

| Upper | Full-Grain Leather, Nubuck, CORDURA | Durability, Breathability, Structure |

| Outsole | Rubber, TPU, PVC | Slip Resistance, Chemical Resistance, Longevity |

| Safety Toe | Steel, Composite (Carbon Fiber) | Impact Protection, Lightweight, Non-Conductive |

Need a reliable supplier for your work boot line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, using the exact materials discussed here—from rugged full-grain leather and steel toes to lightweight composites and advanced synthetics. We can help you source or develop the perfect work boot for your target market, ensuring quality, compliance, and value.

Contact our expert team today to discuss your manufacturing needs and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What are some user experiences with packer boots? Unmatched Durability & All-Day Comfort

- What are the main purposes of safety labels on work boots? A Guide to Choosing the Right PPE

- What does the 'C' in ASTM F2413-18 M/I/C EH PR MT stand for? Essential Guide to Compression Resistance

- What features are often included in welted work boots for comfort? A Guide to All-Day Support

- How should composite toe boots be cared for to ensure longevity? Extend Boot Life with Simple Steps

- Why is it worth investing in a high-quality pair of moc toe boots? For Long-Term Value & Durability

- What clothing items complement the Outdoorsman/Heritage Look with moc toe boots? Build a Timeless, Rugged Wardrobe

- Which material is the most durable for work boots? Find the Right Boot for Your Job