Beyond the classic steel cap, a new generation of safety toes offers certified protection without the traditional weight and conductivity of metal. Non-steel safety toes are primarily made from two categories of materials: advanced composites—such as carbon fiber, Kevlar, fiberglass, and hard plastics—or lightweight metal alloys containing elements like titanium and aluminum. These materials are engineered to meet the same rigorous ASTM safety standards as steel while providing distinct advantages for specific work environments.

The critical takeaway is that choosing a safety toe is no longer a simple matter of steel versus non-steel. It's about understanding the unique properties of composite and alloy materials to find the perfect balance of protection, weight, and environmental suitability for your specific job.

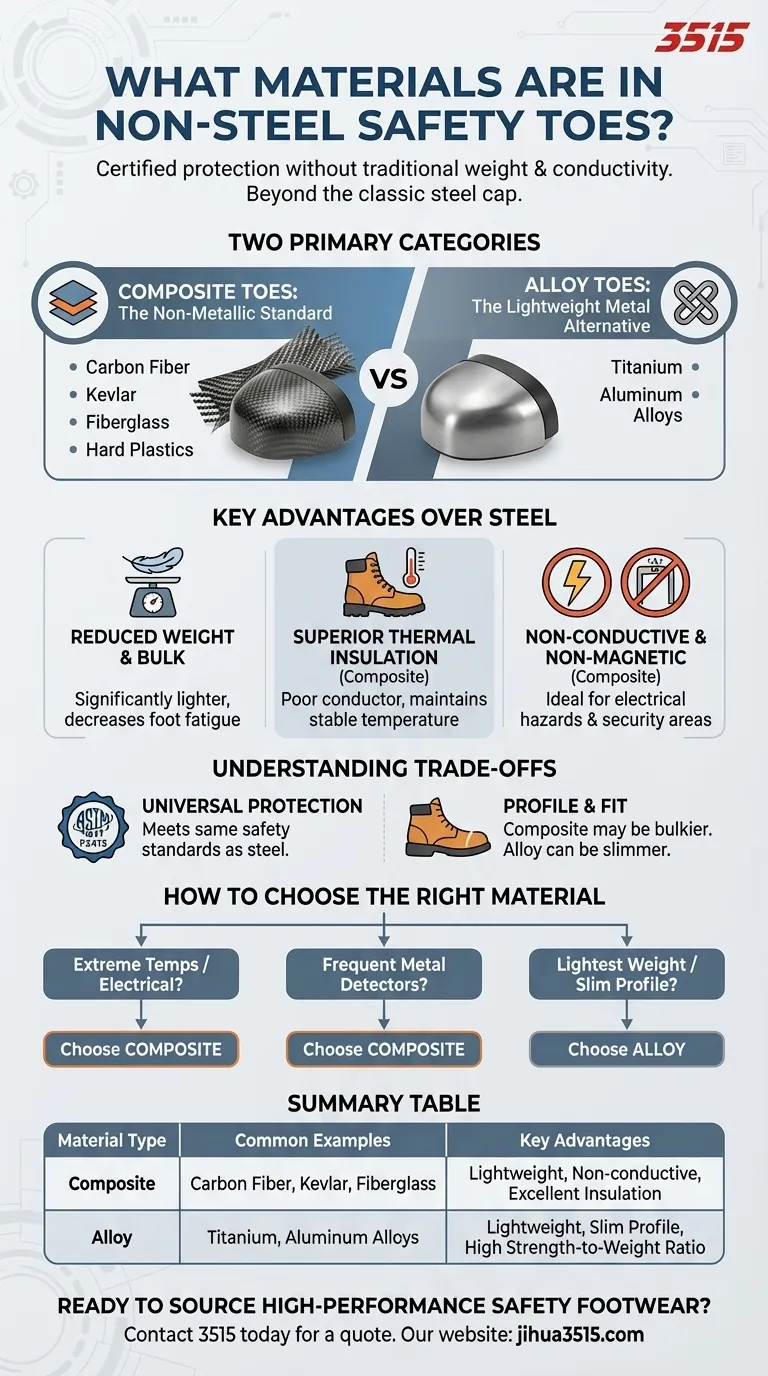

The Two Primary Categories of Non-Steel Toes

While often grouped together, "non-steel" safety toes fall into two distinct material families, each with its own composition and benefits.

Composite Toes: The Non-Metallic Standard

Composite safety toes are crafted by layering non-metallic materials like carbon fiber, fiberglass, Kevlar, or specialized hard plastics.

This layered construction creates a protective cap that is incredibly strong yet significantly lighter than steel. It completely eliminates metal from the toe box.

Alloy Toes: The Lightweight Metal Alternative

Alloy toes are made from a mixture of two or more metals. They are a metallic alternative that is still lighter than traditional steel.

Common components in these alloys include titanium and aluminum, which are prized for their high strength-to-weight ratio.

Key Advantages Over Traditional Steel

The shift away from steel is driven by a need for footwear that does more than just protect against impact. Modern materials enhance comfort and performance in ways steel cannot.

Reduced Weight and Bulk

Both composite and alloy toes offer a significant weight reduction compared to steel. This decreases foot fatigue over long shifts, contributing to overall comfort and endurance.

Superior Thermal Insulation

Steel is an excellent thermal conductor, meaning it quickly becomes uncomfortably hot or cold in extreme temperatures.

Composite materials, by contrast, are poor conductors. They provide far better insulation, helping to maintain a stable and comfortable temperature inside the boot regardless of the external environment.

Non-Conductive and Non-Magnetic Properties (Composite Only)

Because they contain no metal, composite toes are ideal for electricians or others working in environments with electrical hazards.

They also will not trigger metal detectors, making them essential for workers in high-security areas like airports or sensitive government facilities.

Understanding the Trade-offs

While all certified safety toes meet the same impact and compression standards, the material choice involves balancing different factors.

Protection Standards Are Universal

It's a common misconception that non-steel options are less protective. Any safety toe sold in compliant footwear, whether steel, composite, or alloy, must pass the same ASTM F2413 standard. The core level of safety is comparable across all certified materials.

Profile and Fit

To achieve the same strength as steel, a composite toe may sometimes need to be slightly bulkier. Conversely, modern alloy toes can often provide a slimmer profile than both steel and composite options, which can affect the fit and feel of the boot.

How to Choose the Right Material for Your Job

Selecting the correct safety toe material is about matching its properties to the demands and hazards of your workplace.

- If your primary focus is working in extreme temperatures or around electricity: Choose a composite toe for its superior insulation and non-conductive properties.

- If your primary focus is passing through metal detectors frequently: A composite toe is the only non-metallic option and is essential for this need.

- If your primary focus is achieving the lightest possible weight with a slim profile: An alloy toe is often the best choice, providing strength that is comparable to steel at a fraction of the weight.

By understanding these material differences, you can select safety footwear that provides not just certified protection, but also superior comfort and performance for your specific needs.

Summary Table:

| Material Type | Common Examples | Key Advantages |

|---|---|---|

| Composite | Carbon Fiber, Kevlar, Fiberglass | Lightweight, Non-conductive, Excellent Insulation |

| Alloy | Titanium, Aluminum Alloys | Lightweight, Slim Profile, High Strength-to-Weight Ratio |

Ready to source high-performance safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots with composite, alloy, and steel toes for distributors, brand owners, and bulk clients. We ensure all our products meet rigorous ASTM safety standards while delivering the comfort and performance your customers need.

Contact 3515 today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What are the pros and cons of artificial leather in motorcycle boots? Choose the Right Material for Your Ride

- What makes these boots suitable for sensitive electronic environments? ESD Protection Explained

- What performance requirements must sensor hardware meet in safety shoes? High-Precision Biofeedback Standards

- What are the primary benefits of using oilfield safety shoes? Maximize Protection on the Rig

- What are the advantages of self-modeling and stretchable materials for shoe uppers? Unlock Ergonomic Safety & Comfort

- What types of insoles are used in safety boots, and how do they improve comfort? Choose the Right Support for Your Job

- How does Warehouse Capacity (Wcap) contribute to the long-term supply chain integration of safety shoes? Boost Stability

- What technical features are required in work shoes for manual collection on plantations? Essential Safety Standards