In short, the most common insoles in safety boots are made from foam, gel, or feature air-cushioning. Each type is engineered to solve a specific problem, from providing foundational support to absorbing the shock of walking on hard surfaces all day. Their primary purpose is to reduce foot fatigue and dramatically improve wearer comfort over long shifts.

The right insole isn't just a piece of padding; it's a critical component that matches the boot to your foot and your job. Understanding the difference between cushioning, shock absorption, and personalized support is the key to eliminating foot fatigue.

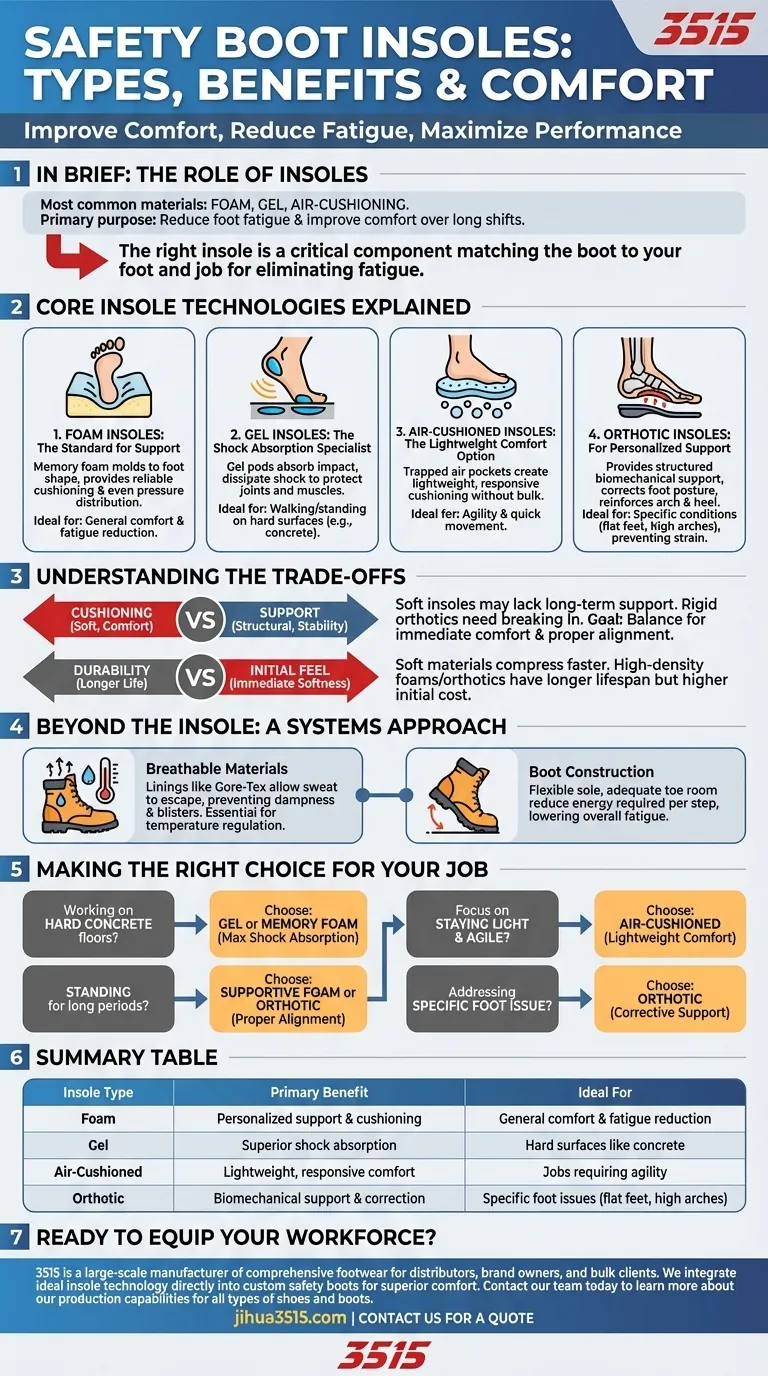

The Core Insole Technologies Explained

Choosing an insole starts with understanding the material science behind it. Each type offers a distinct advantage depending on your daily tasks and foot mechanics.

Foam Insoles: The Standard for Support

Foam, particularly memory foam, is the workhorse of the insole world. It provides a reliable combination of cushioning and support.

This material molds to the unique shape of your foot, offering a personalized fit that distributes pressure evenly across the sole. This makes it an excellent all-around choice for general comfort and fatigue reduction.

Gel Insoles: The Shock Absorption Specialist

Gel insoles are specifically designed to absorb impact. They are ideal for workers who spend long hours walking or standing on unforgiving surfaces like concrete.

The gel pods, often placed in the heel and forefoot, dissipate the shock that would otherwise travel up your legs and back. This targeted protection is crucial for preventing joint pain and muscle soreness.

Air-Cushioned Insoles: The Lightweight Comfort Option

These insoles use trapped air pockets to create a lightweight and responsive cushioning effect. They provide a high level of comfort without adding significant weight or bulk to the boot.

This makes them a great option for workers who value agility and need to move quickly throughout the day.

Orthotic Insoles: For Personalized Support

Beyond generic options, orthotic insoles provide structured, biomechanical support. They are designed to correct foot posture and provide specific reinforcement for the arch and heel.

For individuals with flat feet, high arches, or other specific conditions, orthotics are not just about comfort—they are essential for preventing long-term strain and injury.

Understanding the Trade-offs

No single insole is perfect for every situation. It's crucial to understand the inherent compromises to make an informed decision.

Cushioning vs. Support

An extremely soft, cushioned insole might feel comfortable initially but can lack the structural support needed for long-term stability.

Conversely, a highly supportive orthotic might feel rigid at first. The key is to find a balance that provides both immediate comfort and proper alignment.

Durability vs. Initial Feel

Softer materials like basic foams and gels can provide excellent immediate comfort but may compress and lose their effectiveness more quickly.

Higher-density foams or professional-grade orthotics often have a longer lifespan, providing more consistent performance over time, though they may represent a higher initial investment.

Beyond the Insole: A Systems Approach to Comfort

While the insole is critical, it works as part of a larger system. The construction and materials of the boot itself play a significant role in your overall comfort.

The Importance of Breathable Materials

Boots featuring breathable materials or linings like Gore-Tex allow sweat and moisture to escape.

This prevents dampness, which can lead to blisters and make your feet feel cold. Proper temperature regulation is a cornerstone of all-day comfort.

The Impact of Boot Construction

The overall design of the boot, from a flexible sole to adequate toe room, contributes to reducing fatigue. A boot that works with your foot's natural movement requires less energy with every step, making a noticeable difference by the end of the day.

Making the Right Choice for Your Job

Your work environment is the ultimate guide to selecting the right insole. Match the technology to your daily demands for the best results.

- If your primary focus is working on hard concrete floors: Choose a gel or memory foam insole for maximum shock absorption.

- If your primary focus is standing for long periods: Opt for a supportive foam or orthotic insole to maintain proper arch support and alignment.

- If your primary focus is staying light and agile: An air-cushioned insole will provide comfort without adding unnecessary weight.

- If your primary focus is addressing a specific foot issue (like flat feet): A dedicated orthotic insole is the only choice for providing true corrective support.

By investing in the right insole, you are taking direct control over your comfort and well-being on the job.

Summary Table:

| Insole Type | Primary Benefit | Ideal For |

|---|---|---|

| Foam | Personalized support & cushioning | General comfort & fatigue reduction |

| Gel | Superior shock absorption | Hard surfaces like concrete |

| Air-Cushioned | Lightweight, responsive comfort | Jobs requiring agility |

| Orthotic | Biomechanical support & correction | Specific foot issues (flat feet, high arches) |

Ready to equip your workforce with safety boots featuring the perfect insoles? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. We can integrate the ideal insole technology—from foam and gel to orthotic support—directly into your custom safety boots, ensuring superior comfort and reducing fatigue for the end-user. Let's discuss your specific needs and volume requirements. Contact our team today to get a quote and learn more about our production capabilities for all types of shoes and boots.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?