The primary feature that makes these boots suitable for sensitive electronic environments is their ability to manage and control electrostatic discharge (ESD). They are specifically engineered to prevent the sudden flow of static electricity from a person's body into a component, which could otherwise cause catastrophic damage.

The human body constantly generates static electricity, which can instantly destroy sensitive electronic components. ESD-safe footwear acts as a controlled pathway, safely grounding the wearer and dissipating this static charge before it can cause damage.

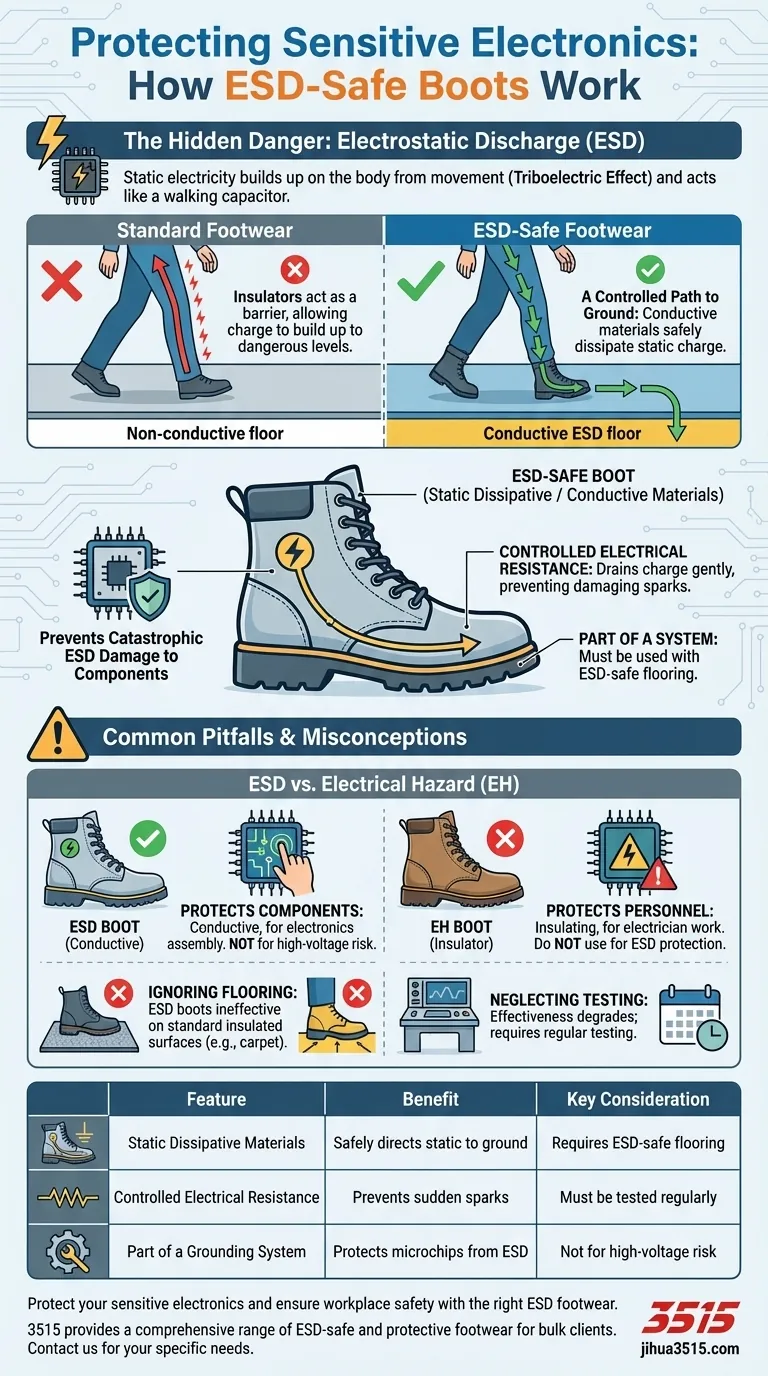

The Hidden Danger: Understanding Electrostatic Discharge (ESD)

To appreciate why specialized footwear is necessary, we must first understand the threat it's designed to prevent.

How Static Builds Up

As you walk or move, the simple friction between your clothes and your body, or your shoes and the floor, generates an electrical charge. This is known as the triboelectric effect.

This charge builds up on your body, turning you into a walking capacitor, ready to discharge at the first opportunity.

The Threat to Electronics

While a static shock might be a minor annoyance to a person, it is a catastrophic event for a modern microchip or circuit board.

A discharge that is too small for a human to even feel can carry enough voltage to permanently destroy the microscopic internal structures of a component.

The Problem with Standard Footwear

Most conventional shoes, especially those with rubber or synthetic soles, are electrical insulators.

Insulators prevent the static charge on your body from safely dissipating into the ground. This allows the charge to accumulate to dangerous levels, making an uncontrolled discharge more likely.

How ESD-Safe Boots Provide Protection

ESD-safe footwear is not an insulator; it is engineered to be part of a grounding system that continuously and safely removes static charge.

A Controlled Path to Ground

These boots are constructed with materials, such as carbon-infused compounds, that are static dissipative or conductive.

This allows the electrical charge on your body to flow through the boot and into a specially designed ESD-safe floor, effectively grounding you.

Dissipating Charge Safely

The goal is not just to discharge the electricity, but to do so in a slow, controlled manner.

ESD-safe boots are designed with a specific range of electrical resistance. This ensures the static drains away gently rather than in a sudden, damaging spark.

A Critical Part of a System

It is crucial to understand that these boots do not work in isolation.

They are one component of a complete ESD control system. For them to function, the wearer must be standing on a grounded, ESD-safe floor or mat.

Common Pitfalls and Misconceptions

Selecting the wrong footwear can create a false sense of security or, in some cases, introduce new hazards.

Confusing ESD with Electrical Hazard (EH)

This is the most critical distinction. Electrical Hazard (EH) rated boots are thick insulators designed to protect the wearer from shock if they step on a live electrical circuit.

ESD boots are the functional opposite; they are conductive. Wearing ESD boots in an environment with high-voltage shock risk is extremely dangerous.

Ignoring the Flooring

ESD boots are completely ineffective on an insulated surface like a standard office carpet or sealed concrete floor.

Without a conductive path from the boot's sole to the ground, the static charge has nowhere to go.

Neglecting Maintenance and Testing

The effectiveness of ESD footwear can degrade over time due to dirt, debris, and wear.

For this reason, facilities with strict ESD protocols often require daily testing of footwear to ensure it remains within its specified resistance range.

Making the Right Choice for Your Environment

To ensure safety and effectiveness, your choice must align with your specific operational goal.

- If your primary focus is protecting sensitive components (e.g., electronics assembly, data centers): You must use certified ESD-safe footwear in conjunction with a properly grounded flooring system.

- If your primary focus is protecting personnel from live electrical circuits (e.g., electrician work): You must use Electrical Hazard (EH) rated boots, which are insulators and are fundamentally different from ESD footwear.

- If your focus is chemical resistance in an industrial setting: You need boots made from specifically formulated chemical-resistant materials, which may or may not have ESD properties.

Choosing the correct footwear is a critical and non-negotiable step in creating a safe and reliable electrostatic-protected area.

Summary Table:

| Feature | Benefit | Key Consideration |

|---|---|---|

| Static Dissipative Materials | Safely directs static charge to the ground | Requires use with ESD-safe flooring |

| Controlled Electrical Resistance | Prevents sudden, damaging sparks | Must be tested regularly for effectiveness |

| Part of a Grounding System | Protects microchips and circuit boards from ESD damage | Not for use in high-voltage shock risk environments |

| Different from EH-rated Boots | Designed for electronics protection, not personal electrical hazard insulation | Critical to choose based on primary operational goal |

Protect your sensitive electronics and ensure workplace safety with the right ESD footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of ESD-safe and protective footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, engineered to meet stringent industry standards.

We can provide the precise ESD-safe footwear your operations require, ensuring component protection and compliance.

Contact us today to discuss your specific needs and request a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What is the role of the midsole in safety shoes? The Key to Comfort and Protection

- What are composite toe work boots and what are their benefits? Lightweight, Non-Conductive Safety Footwear

- How does a dual-belt medical treadmill contribute to the gait analysis of safety footwear? Precision Kinetic Testing

- How do professional protective footwear or shoe covers control contamination? Elevate Medical Ward Safety & Hygiene

- Why are industrial safety shoes necessary for mining machinery maintenance? Protect Feet from Crushing and Punctures

- What are the key features of safety shoe soles? A Complete Guide to Workplace Foot Protection

- How does professional protective footwear assist in preventing Low Back Pain (LBP)? Ergonomic Solutions for Heavy Labor

- Why are multiple piezoelectric transducers connected in parallel? Boosting Current for Smart Safety Shoes