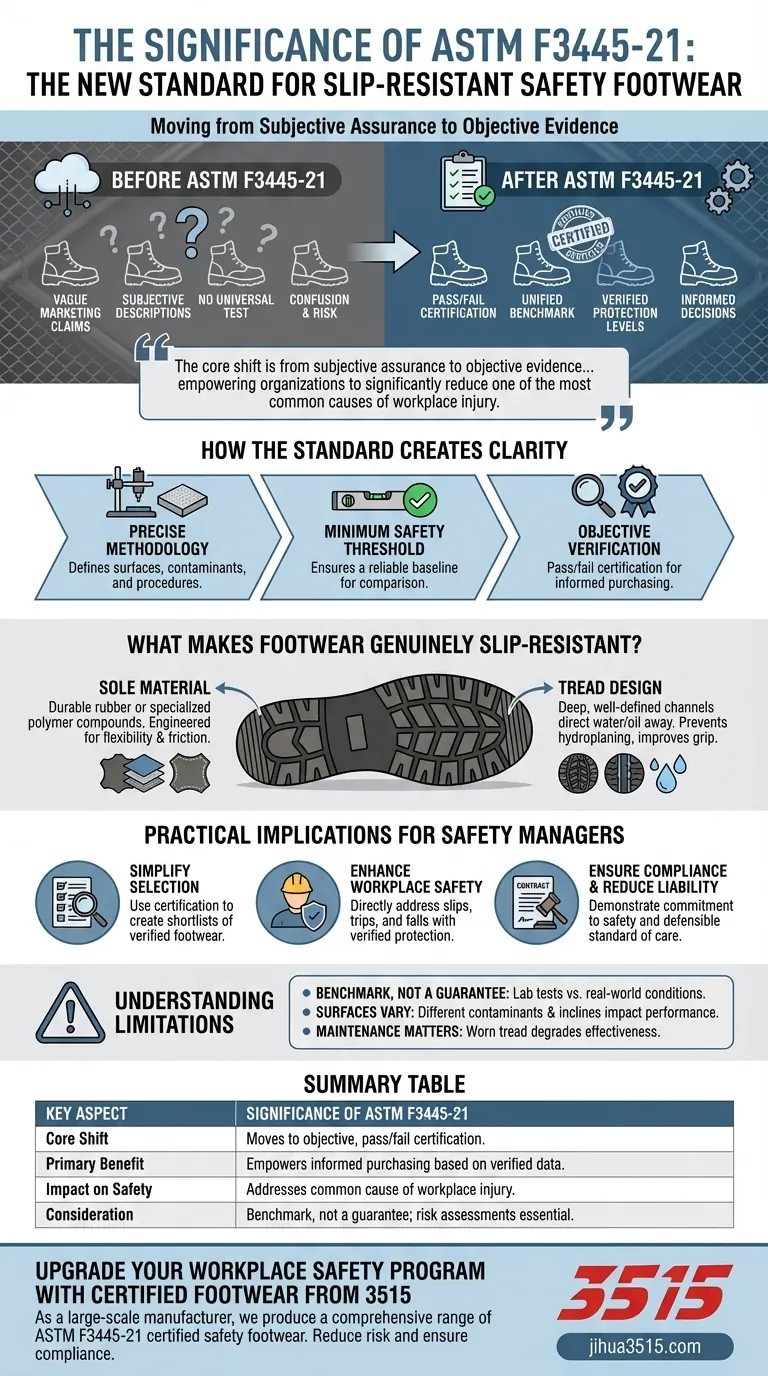

The single greatest significance of the new ASTM F3445-21 standard is that it establishes a clear, unified, and testable benchmark for slip-resistant safety footwear. It replaces vague marketing claims with a pass/fail certification, giving safety professionals an objective tool to verify protection levels and make informed purchasing decisions.

The core shift is from subjective assurance to objective evidence. For the first time, a "slip-resistant" label on safety footwear can be backed by a standardized, verifiable test, empowering organizations to significantly reduce one of the most common causes of workplace injury.

From Ambiguity to a Clear Standard

For years, selecting slip-resistant footwear was a significant challenge. The lack of a single, required standard created confusion and risk for safety managers and employees alike.

The Problem with Vague Claims

Historically, terms like "slip-resistant" or "high-traction" were marketing descriptions, not technical specifications. There was no universal method to substantiate these claims, leaving buyers to rely on brand reputation or tread design appearance alone.

Introducing ASTM F3445-21

The ASTM F3445-21 standard specification directly addresses this problem. It outlines a precise testing methodology that footwear must pass to be officially certified for slip resistance under specific conditions.

How a Standard Creates Clarity

This standard defines the exact surfaces, contaminants (like water or oil), and testing procedures to be used. This ensures that every certified boot has met the same minimum safety threshold, providing a reliable baseline for comparison and selection.

What Makes Footwear Genuinely Slip-Resistant?

While the standard provides a benchmark, it's still crucial to understand the physical characteristics that enable a boot to pass these rigorous tests. The design and material of the outsole are the most critical factors.

The Role of Sole Material

High-performance slip-resistant soles are typically made from durable rubber or specialized polymer compounds. These materials are engineered to maintain their flexibility and provide a strong coefficient of friction against various surfaces.

The Importance of Tread Design

Effective footwear features deep, well-defined tread patterns. These channels are not just for show; they are designed to direct water, oil, and other debris away from the sole's contact points, preventing hydroplaning and improving direct grip on the ground.

The Practical Implications for Safety Managers

The introduction of ASTM F3445-21 is a significant development for anyone responsible for occupational health and safety. It simplifies processes and elevates the standard of care.

Simplifying the Selection Process

Safety managers no longer need to interpret ambiguous product descriptions. They can simply look for the ASTM F3445-21 certification to create a shortlist of footwear that meets a verified safety benchmark.

Enhancing Workplace Safety

By mandating certified footwear, you can directly address one of the leading causes of workplace accidents—slips, trips, and falls. This standard provides a powerful tool to match verified protection to known worksite hazards.

Ensuring Compliance and Reducing Liability

Adopting a recognized international standard like ASTM F3445-21 demonstrates a clear commitment to employee safety. It strengthens your safety program and provides a defensible standard of care in the event of an incident.

Understanding the Limitations

While this standard is a major step forward, it is a tool, not a complete solution. A technical advisor must caution against viewing it as an absolute guarantee of safety in all conditions.

A Benchmark, Not a Guarantee

The ASTM test is performed in a controlled laboratory setting. Real-world conditions—with unexpected contaminants, worn surfaces, and dynamic movements—can present greater challenges than the test accounts for.

Not All Surfaces Are the Same

A boot that passes the standard test on a wet tile surface may perform differently on greasy metal, loose gravel, or icy inclines. The standard provides an excellent baseline, but site-specific risk assessments remain essential.

Maintenance Still Matters

The slip-resistant properties of any footwear degrade over time. A worn-out tread or a sole caked with mud will not perform as designed, regardless of its initial certification. Regular inspection and replacement are critical.

Making the Right Choice for Your Environment

Use the ASTM F3445-21 standard as the foundation of your footwear safety program, not the entirety of it. Your specific workplace hazards should always guide your final decision.

- If your primary focus is compliance and general safety: Mandate that all new safety footwear must meet or exceed the ASTM F3445-21 standard.

- If your environment has specific liquid hazards: Use the standard as a filter, then verify that the chosen footwear's sole material is chemically resistant to the specific oils or fluids present.

- If you manage a highly varied or rugged worksite: Require footwear certified to the standard as a baseline, but conduct practical assessments for extreme conditions like steep grades or unique surfaces.

By leveraging this clear standard, you can move from guesswork to confidence in your workplace safety strategy.

Summary Table:

| Key Aspect | Significance of ASTM F3445-21 |

|---|---|

| Core Shift | Moves from subjective marketing claims to objective, pass/fail certification. |

| Primary Benefit | Empowers safety managers to make informed purchasing decisions based on verified data. |

| Impact on Safety | Provides a tool to directly address one of the most common causes of workplace injury. |

| Consideration | A benchmark, not an absolute guarantee; site-specific risk assessments are still essential. |

Upgrade your workplace safety program with certified footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F3445-21 certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of slip-resistant shoes and boots, engineered with durable materials and effective tread patterns to meet this crucial standard.

Let us help you reduce risk and ensure compliance. Contact our experts today to discuss your specific needs and request a catalog.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- Why are professional conveyor systems used for process flow management in safety shoe production? Ensure Consistency

- What role does seamless and non-binding construction play in footwear? Enhance Vascular Health & Prevent Skin Breakage

- What factors contribute to the comfort and fit of safety footwear? Find the Perfect Fit for Your Workforce

- What is the importance of puncture-resistant midsoles in safety shoes? Protect Workers from Industrial Hazards

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- How significant are slips, trips, and falls in workplace injuries? The $13 Billion Problem

- What is the purpose of the heel cap in safety footwear? Essential for Stability and Injury Prevention

- What is the role of professional industrial safety shoes in HIRARC? Essential Risk Mitigation for Manufacturing