The primary factors contributing to the comfort and fit of safety footwear are a combination of proper arch support, adequate cushioning for shock absorption, and a fit that is snug enough to prevent sliding without being restrictive. The boot's internal shape, particularly the width of the toe box, along with the materials used for breathability and weight, are also critical for all-day comfort and consistent use.

The comfort of your safety footwear is not a luxury; it is a critical component of your personal protective equipment (PPE). True comfort and a proper fit are achieved when the boot's design aligns perfectly with your unique foot anatomy and the physical demands of your job.

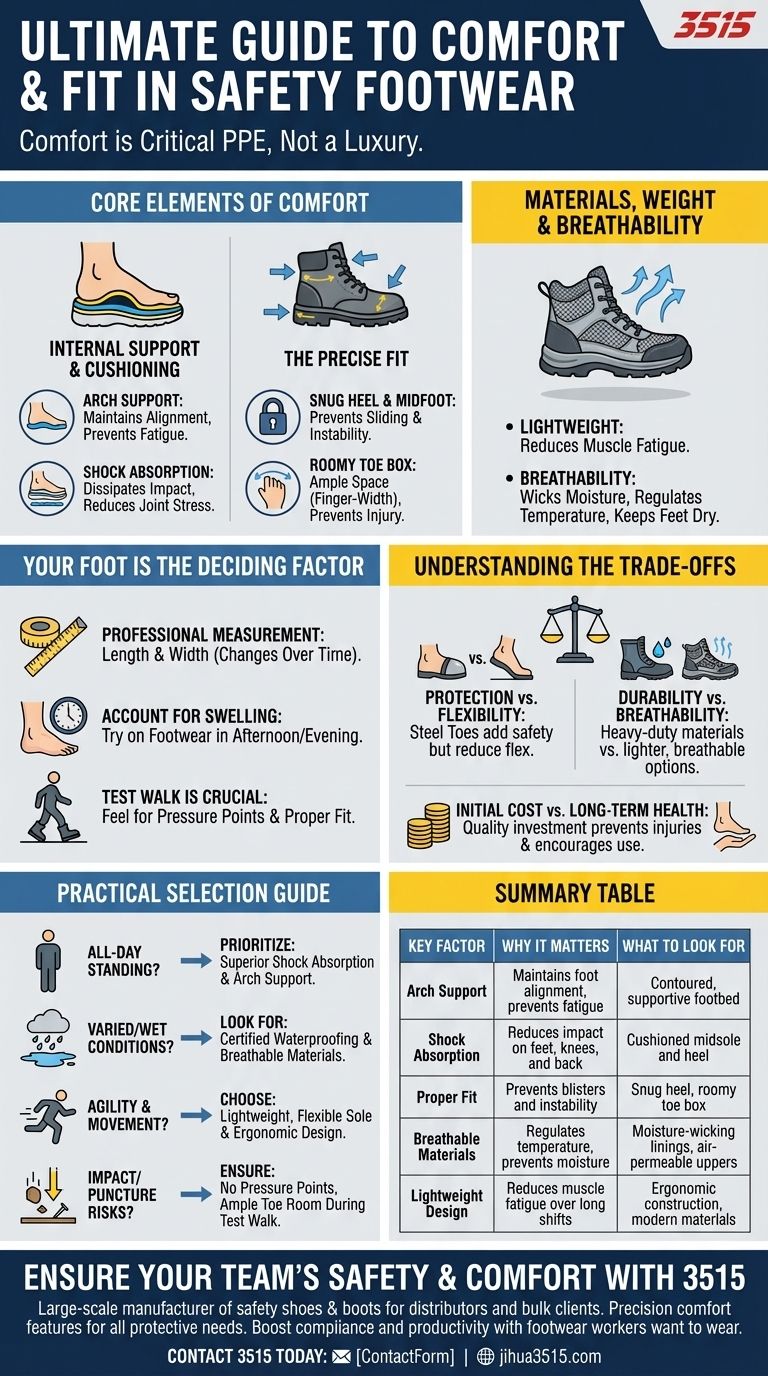

The Core Elements of Footwear Comfort

Understanding the specific components that create a comfortable boot allows you to assess footwear beyond just its safety rating.

Internal Support and Cushioning

Proper internal structure is the foundation of comfort. It directly combats the fatigue that comes from standing or walking on hard surfaces for long hours.

Arch support is essential for maintaining proper foot alignment and preventing conditions like plantar fasciitis. A well-designed insole or footbed will cradle the natural arch of your foot.

Shock absorption, typically found in the midsole and heel, dissipates the force of impact with each step. This reduces stress not only on your feet but also on your joints, including your ankles, knees, and back.

The Importance of a Precise Fit

A boot that fits poorly can be as hazardous as no protection at all, causing blisters, calluses, and long-term foot problems.

A proper fit should be snug around the heel and midfoot to prevent your foot from sliding, which can cause friction and instability.

However, there must be ample room in the toe box. You should have at least a finger-width of space between your longest toe and the end of the boot, allowing your toes to spread naturally as you walk. Shoes that are too narrow or shallow are a leading cause of forefoot injuries.

Materials, Weight, and Breathability

The materials used in the boot's construction have a significant impact on your daily experience.

Lightweight materials and an ergonomic design reduce muscle activity and fatigue, making a noticeable difference over a long shift.

Breathability is also key. Linings that wick away moisture and uppers that allow for air circulation help regulate temperature, keeping your feet dry and reducing the risk of fungal infections and blisters.

Why Your Foot Shape is the Deciding Factor

No boot can be comfortable if it doesn't match the unique dimensions of your foot. Off-the-shelf sizes are a starting point, not a guarantee.

Understanding Your Foot's Dimensions

It is crucial to have your feet professionally measured for both length and width. Foot size and shape can change over time due to age or weight, so periodic re-measurement is a good practice.

Accounting for Daily Swelling

Your feet naturally swell throughout the day. To ensure a comfortable fit from the start of your shift to the end, always try on new footwear in the afternoon or evening when your feet are at their largest.

The Power of a Test Walk

Never buy safety footwear without walking around in it first. This is the only way to feel for potential pressure points, rubbing, or an improper fit that isn't immediately obvious when sitting down.

Understanding the Trade-offs

Choosing the right footwear often involves balancing competing needs. Being aware of these trade-offs helps you make a more informed decision.

Protection vs. Flexibility

Highly protective features, like steel toe caps and puncture-resistant plates, are non-negotiable in many environments. However, they can add weight and reduce the boot's overall flexibility. The key is to find a model where these features are integrated ergonomically.

Durability vs. Breathability

Heavy-duty, waterproof materials provide excellent protection against liquids and corrosive substances but may be less breathable than lighter synthetic options. Your choice should be guided by the specific environmental hazards of your workplace.

Initial Cost vs. Long-Term Health

High-quality, comfortable safety footwear is an investment in your health. Cheaper boots may save money initially but often lead to discomfort, fatigue, and foot injuries, which discourages consistent PPE use and can result in higher costs long-term.

A Practical Guide to Selecting Your Footwear

Use your primary work activity as a guide to prioritize the most important comfort features for your needs.

- If your primary focus is all-day standing on hard surfaces: Prioritize footwear with superior shock absorption and pronounced arch support to minimize fatigue.

- If your primary focus is working in varied or wet conditions: Look for a balance of certified waterproofing and high-quality breathable materials to keep your feet dry.

- If your primary focus is agility and frequent movement: Choose lightweight boots with a flexible sole and an ergonomic design that supports natural foot motion.

- If your primary focus is protection from impact or puncture: Ensure the protective components do not create pressure points or cramp your toes during a test walk.

Making a deliberate, informed choice based on comfort and fit is the best way to guarantee both your safety and your well-being at work.

Summary Table:

| Key Factor | Why It Matters | What to Look For |

|---|---|---|

| Arch Support | Maintains foot alignment, prevents fatigue | Contoured, supportive footbed |

| Shock Absorption | Reduces impact on feet, knees, and back | Cushioned midsole and heel |

| Proper Fit | Prevents blisters and instability | Snug heel, roomy toe box |

| Breathable Materials | Regulates temperature, prevents moisture | Moisture-wicking linings, air-permeable uppers |

| Lightweight Design | Reduces muscle fatigue over long shifts | Ergonomic construction, modern materials |

Ensure your team's safety and comfort with perfectly fitted footwear from 3515.

As a large-scale manufacturer, we produce a comprehensive range of safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, designed with the precise comfort features detailed above.

We can help you provide footwear that workers will want to wear, boosting compliance and productivity.

Contact 3515 today to discuss your specific needs and request samples.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- How can you determine the right safety toe boot for your workplace? Match Boots to Hazards

- What is the benefit of incorporating modern aesthetics and industrial design into safety shoes? Drive Compliance Now

- What is a potential drawback of composite toes after an impact? The Hidden Danger of 'One-and-Done' Failure

- What role do integrated pressure-sensing insoles play in safety shoes for assessing lower back disease risk?

- What is the primary function of Structural Equation Modeling (SEM) when analyzing consumer repeat purchase intentions for industrial and protective footwear? Gain Actionable Insights for Loyalty & Sales

- What should safety shoes have? Essential Features for Ultimate Workplace Protection

- What are the advantages of rubber soles in safety boots? Unbeatable Grip & Durability

- What should customers consider when choosing safety footwear? A Guide to Perfect Fit & Protection