The most critical factors in choosing the best work boots are your specific work environment, the required safety features dictated by job site hazards, and the materials used in the boot's construction. A boot designed for an electrician has fundamentally different priorities than one for a construction worker, making a one-size-fits-all approach both ineffective and unsafe.

The right work boot is not simply the most durable or protective one available; it is a specialized tool engineered to provide the precise balance of safety, comfort, and durability your specific job demands.

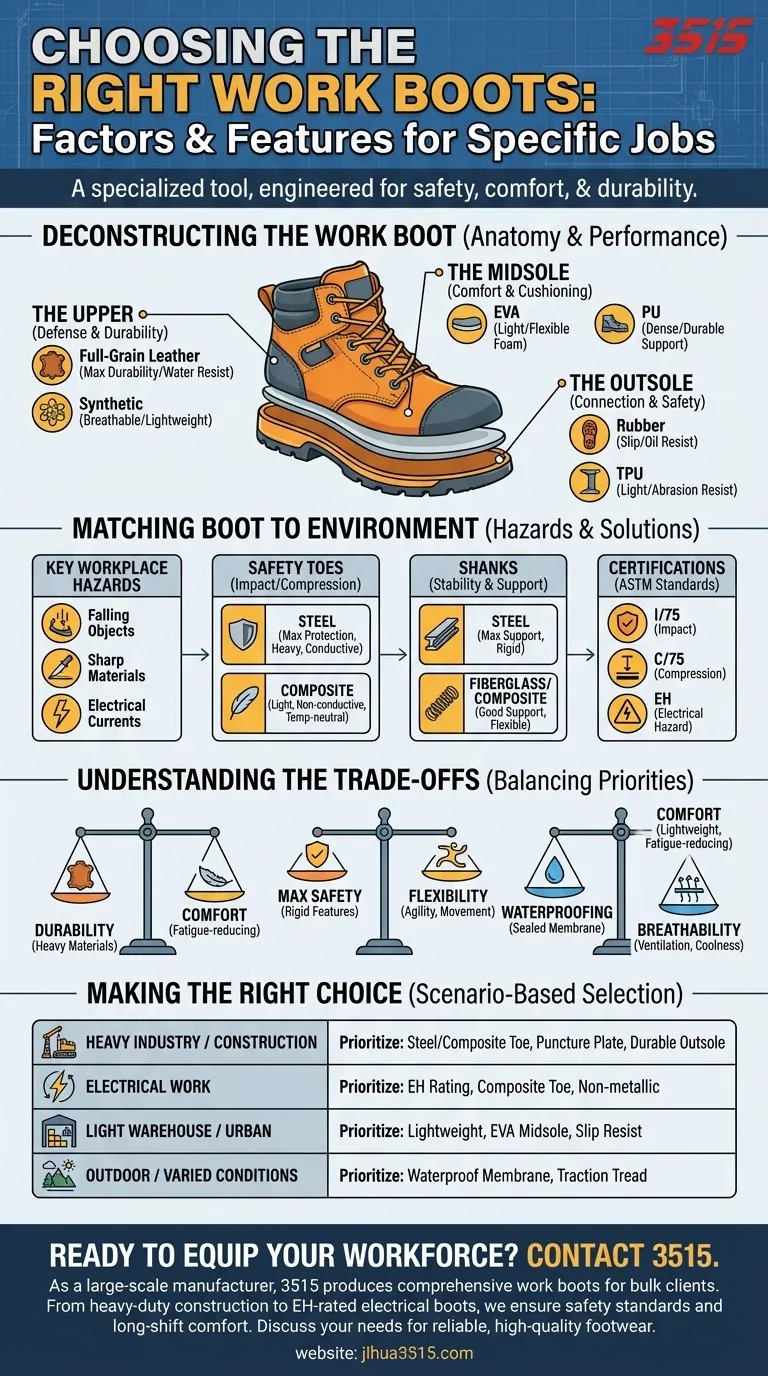

Deconstructing the Work Boot

To make an informed choice, you must first understand the core components of a work boot and how they contribute to its performance. Each part serves a distinct purpose.

The Upper: Your First Line of Defense

The "upper" is everything above the sole. Its material dictates the boot's durability, breathability, and resistance to the elements.

Full-grain leather is the traditional choice, offering maximum durability and water resistance. Lighter work may allow for synthetic materials, which improve breathability and reduce weight.

The Outsole: Your Connection to the Ground

The outsole is the layer that makes direct contact with the ground. Its material and tread pattern are critical for safety and longevity.

Rubber is common, providing excellent slip and oil resistance. Thermoplastic Polyurethane (TPU) is a more lightweight and abrasion-resistant alternative often found in higher-end boots.

The Midsole: The Core of Comfort

Sandwiched between the insole and the outsole, the midsole provides cushioning and absorbs shock. This is the primary source of all-day comfort.

EVA (ethylene vinyl acetate) is a lightweight and flexible foam that provides excellent cushioning. Polyurethane (PU) is denser and more durable, offering longer-lasting support in demanding conditions.

Matching the Boot to Your Environment

Beyond construction, the most important step is to analyze the specific hazards and requirements of your daily work. This analysis will guide your selection of crucial safety features.

Identifying Key Workplace Hazards

First, assess your environment. Do you face risks from falling objects, sharp materials on the ground, or electrical currents? Each hazard requires a specific protective feature.

The Role of Safety Toes

Safety toes protect your feet from impact and compression. The choice of material affects weight, protection level, and conductivity.

Steel toes offer the maximum protection but are the heaviest and conduct temperature. Composite toes (made of carbon fiber, plastic, or Kevlar) are lighter, do not conduct electricity, and are better for temperature-varying environments.

Understanding Shanks for Stability

A shank is a rigid piece placed between the midsole and outsole that adds support and stability, especially when climbing ladders or walking on uneven terrain.

Steel shanks provide maximum support but can be rigid. Fiberglass or composite shanks offer good support with less weight and more flexibility.

Meeting Safety Certifications

Always look for a boot's ASTM (American Society for Testing and Materials) rating. These certifications guarantee the boot has been tested to meet specific safety standards for things like impact resistance (I/75), compression resistance (C/75), and electrical hazard protection (EH).

Understanding the Trade-offs

Selecting a work boot is an exercise in balancing competing priorities. Excelling in one area often means compromising in another.

Durability vs. Comfort

Heavier, more robust materials like full-grain leather and steel components offer superior durability. However, they significantly increase the boot's weight, which can lead to fatigue over a long workday.

Maximum Safety vs. Flexibility

Boots with extensive safety features like steel toes, shanks, and puncture-resistant plates provide comprehensive protection. This added structure can make the boot stiffer and reduce your agility.

Waterproofing vs. Breathability

A fully waterproof membrane is essential for wet environments, but it inherently limits the boot's ability to breathe. In hot, dry climates, this can lead to excessive sweat and discomfort.

Making the Right Choice for Your Job

Your goal is to align the boot's features with the primary demands of your work. Use your hazard assessment to find the optimal balance of protection, support, and comfort.

- If your primary focus is heavy industry or construction: Prioritize maximum protection with a steel or composite safety toe, a puncture-resistant plate, and a durable, slip-resistant outsole.

- If your primary focus is electrical work: Insist on a boot with an Electrical Hazard (EH) rating and choose non-metallic components like a composite toe.

- If your primary focus is light warehouse or urban work: Emphasize comfort and fatigue-reduction with a lightweight design, an EVA midsole, and good slip resistance.

- If your primary focus is outdoor work in varied conditions: Select a boot with a reliable waterproof membrane and a tread pattern designed for traction on uneven, natural surfaces.

Ultimately, viewing your work boots as a critical piece of personal protective equipment will guide you to the correct choice.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Work Environment | Hazards present (electrical, impact, slips), indoor/outdoor, temperature. |

| Safety Features | Safety toe type (steel, composite), shank, puncture plate, ASTM certifications (I/75, C/75, EH). |

| Materials & Construction | Upper (leather, synthetic), outsole (rubber, TPU), midsole (EVA, PU) for durability and comfort. |

| Primary Job Focus | Heavy industry, electrical work, warehouse, or outdoor conditions dictate feature priority. |

Ready to equip your workforce with the perfect safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of specialized work boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, from heavy-duty boots with steel toes and puncture-resistant plates for construction to EH-rated composite toe boots for electricians. We ensure every pair meets rigorous safety standards while providing the comfort needed for long shifts.

Contact 3515 today to discuss your specific needs and discover how our manufacturing expertise can provide reliable, high-quality footwear for your customers or workforce.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- Why are high-durability work boots essential for stone cutting? Protect Operators from High-Velocity Shards

- What are the key features of work boots for commercial fishing? Essential Safety & Durability Guide

- What is the significance of safety training with safety boots? Maximizing Protection in High-Risk Zones

- What should be considered for comfort and fit in farming and gardening boots? Ensure Long-Term Endurance

- What are the different types of firefighter boots and their features? Essential Guide for Safety & Performance

- What are some tips for wearing engineer boots? Master the Pants-to-Boot Silhouette

- What are the risks of using ordinary rubber boots in forest clearing? Why professional safety boots are essential

- What factors determine the durability of construction boots? A Guide to Long-Lasting Work Footwear