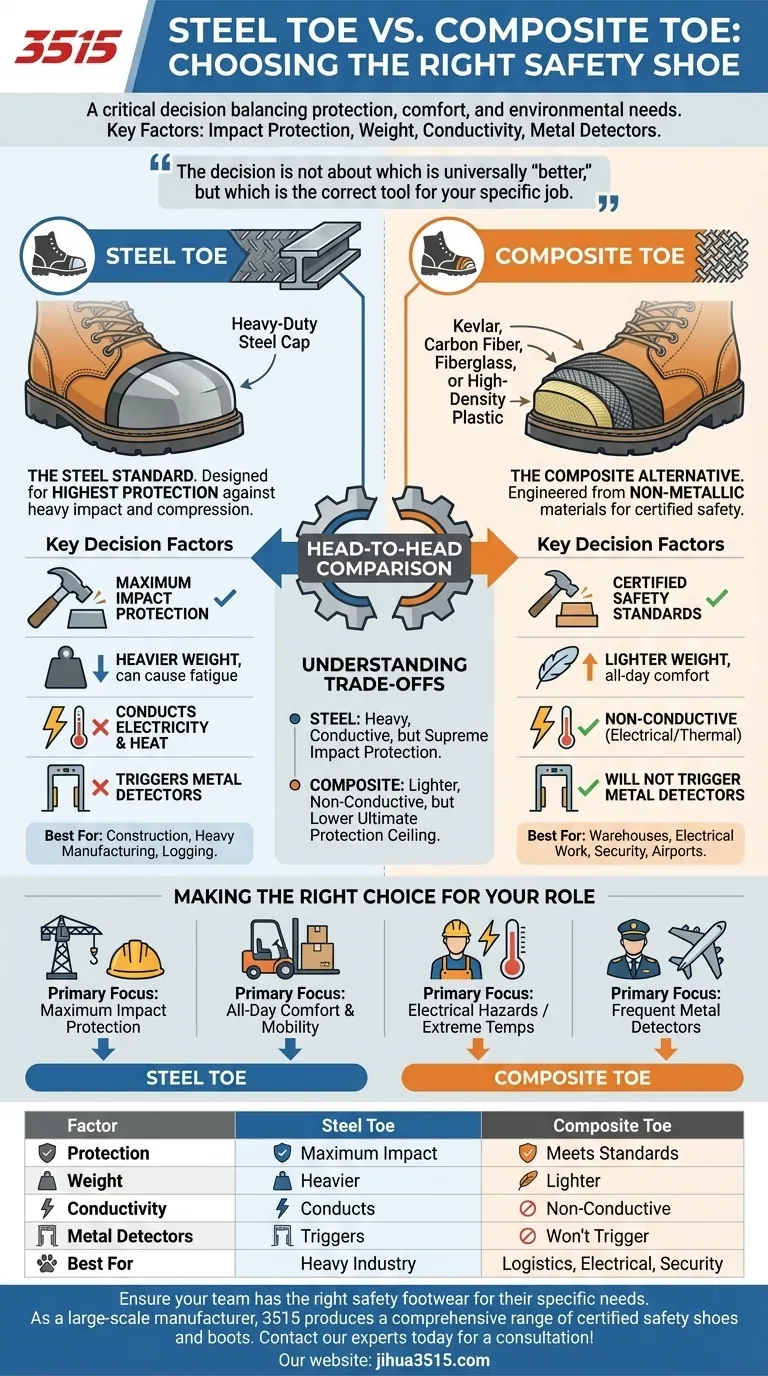

Choosing the right safety shoe is a critical decision that balances protection, comfort, and environmental needs. The primary factors to consider are the required level of impact protection, the shoe's weight, its conductivity of heat and electricity, and whether you work in an environment with metal detectors.

The decision between composite and steel toe shoes is not about which is universally "better," but which is the correct tool for your specific job. Steel offers maximum protection against impact and compression, while composite provides a lighter, non-conductive alternative ideal for certain specialized environments.

Breaking Down the Core Materials

Understanding the fundamental difference in materials is the first step in making an informed choice. Each material is engineered with a distinct set of properties and priorities.

The Steel Standard

Steel toe caps are the traditional standard for safety footwear. They are designed for one primary purpose: to provide the highest possible level of protection against heavy impact and compression hazards.

These caps are formed from heavy-duty steel, offering robust and reliable safety in high-risk environments.

The Composite Alternative

Composite toe caps are the modern evolution, engineered from non-metallic materials. These can include Kevlar, carbon fiber, fiberglass, or high-density plastics.

The goal of composite materials is to provide certified safety protection while eliminating the weight and conductivity associated with steel.

A Note on Alloy Toes

A third category, alloy toes, also exists. These are crafted from lightweight metals like aluminum or titanium.

Alloy toes serve as a middle ground, offering protection comparable to steel but in a lighter, less bulky package. However, they are still metallic and will conduct electricity and trigger metal detectors.

Key Decision Factors: A Head-to-Head Comparison

Your specific work environment and daily tasks will determine which features are most important. A direct comparison reveals clear advantages for each type depending on the context.

Level of Protection

For sheer strength against crushing and impact forces, steel toe shoes offer the strongest protection. They are the preferred choice in industries with a high risk of heavy falling objects, such as construction, heavy manufacturing, and logging.

Composite toes meet the same official safety standards, but they typically do not withstand the same extreme levels of impact that steel can endure.

All-Day Comfort and Weight

This is where composite toes have a significant advantage. By using lightweight, non-metal materials, they dramatically reduce the overall weight of the shoe.

For professionals who are on their feet for long shifts or walk several miles a day, the reduced weight of composite shoes can lead to noticeably less fatigue.

Electrical and Thermal Hazards

Composite materials do not conduct electricity, making them the essential choice for electricians and other professionals working around live circuits.

Similarly, steel is an efficient conductor of temperature. In very cold or hot environments, steel toe caps can become uncomfortable, whereas composite materials provide superior insulation.

Environments with Metal Detectors

If your job requires you to pass through metal detectors frequently, composite toe shoes are the only practical option.

This makes them a requirement for many security, law enforcement, and airport personnel who need safety footwear that won't constantly trigger alarms.

Understanding the Trade-offs

Neither option is perfect for every situation. Being aware of the inherent limitations of each type is crucial for making a safe and practical decision.

The Downside of Steel: Weight and Conductivity

The primary drawbacks of steel are its weight and conductivity. The heavier design can cause fatigue over a long work week, and its ability to conduct electricity and heat makes it unsuitable for certain specialized jobs without proper insulation.

The Limitation of Composite: The Protection Ceiling

While composite toes meet required safety standards, they have a lower ceiling for ultimate protection. In a catastrophic impact event, a steel toe is more likely to provide a higher degree of protection. For the most extreme-risk environments, this difference is a critical consideration.

Making the Right Choice for Your Role

To simplify your decision, match the footwear's primary strength to your most critical job requirement.

- If your primary focus is maximum impact protection (e.g., construction, heavy machinery operation): Steel toe is the most reliable choice for its superior strength.

- If your primary focus is all-day comfort and mobility (e.g., warehouse logistics, trade work): Composite toe will significantly reduce fatigue and increase comfort.

- If your primary focus is working around electrical hazards or in extreme temperatures: Composite toe's non-conductive properties make it the safest and most comfortable option.

- If your primary focus is passing through metal detectors frequently (e.g., security, airports): Composite toe is a non-negotiable requirement for your role.

Selecting the correct safety shoe is a foundational element of your professional safety and daily well-being.

Summary Table:

| Factor | Steel Toe | Composite Toe |

|---|---|---|

| Protection Level | Maximum impact/compression protection | Meets safety standards, lighter protection |

| Weight | Heavier, can cause fatigue | Lighter, better for all-day comfort |

| Conductivity | Conducts electricity and temperature | Non-conductive, ideal for electricians |

| Metal Detectors | Will trigger alarms | Will not trigger alarms |

| Best For | Heavy manufacturing, construction | Warehouses, electrical work, security |

Ensure your team has the right safety footwear for their specific needs. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring durability, comfort, and compliance. Let us help you equip your workforce with the optimal safety solution. Contact our experts today for a consultation and to discuss your requirements!

Visual Guide

Related Products

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- Why are steel toes popular in safety footwear? The Ultimate Guide to Heavy-Duty Protection

- How should steel toe boots be maintained for longevity? A Guide to Maximize Safety and Durability

- Why is it important for organizations to prioritize the use of steel toe shoes? Boost Safety & Productivity

- When are steel-toe boots required or recommended? Essential Guide to Workplace Foot Safety

- What are the two safety standards for steel cap boots in Australia and New Zealand? Choose the Right Protection

- Can an employer require safety-toe footwear at all times? The Legal Basis Explained

- What are the different types of materials used in the toe portion of safety toe work boots? A Guide to Steel, Alloy & Composite

- What safety standards do modern steel toe boots adhere to? Understanding ASTM & EN ISO for Maximum Protection